Adjustable rolling-type sand and stone screening device

A screening device and rolling technology, which is applied in the direction of filter screen, solid separation, grille, etc., can solve the problems of unable to adjust, easy to block the screen holes, etc., achieve simple structure, avoid filter blockage, and easy and fast operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

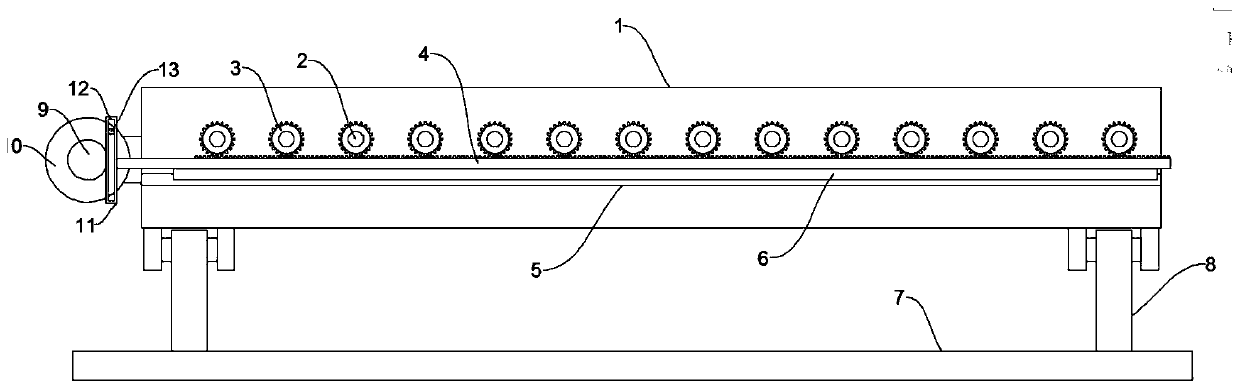

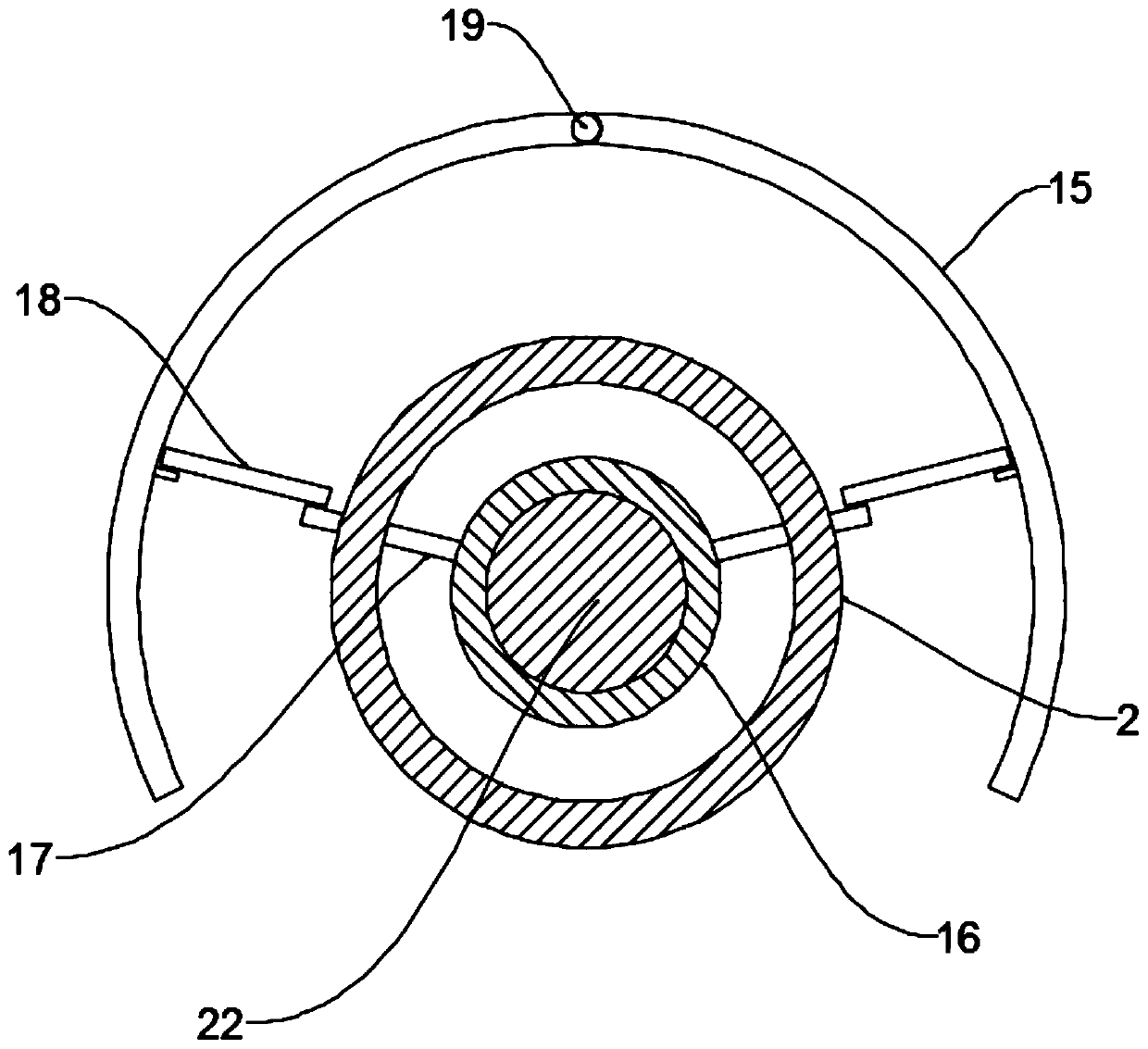

[0025] see figure 1 and 2 , in the embodiment of the present invention, an adjustable rolling sand screening device includes a screening channel 1 and a base substrate 7, the screening channel 1 is installed with the upper side of the base substrate 7, and the screening channel The inside of 1 is provided with a plurality of parallel rotating round rods 2, the axis distance between each rotating round rod 2 is equidistant and each rotating round rod 2 is provided with a baffle plate 14, and each rotating round rod 2 The ends protruding from the side wall of the screening channel 1 are all provided with driving gears 3, and the side of the screening channel 1 is provided with a rack 4 meshing with a plurality of driving gears 3, and the lower end of the rack 4 passes through the The sliding mechanism is connected to the side wall of the screening channel 1, specifically, a limiting guide rail 5 is fixed on the side wall of the screening channel 1, and the limiting guide rail 5...

Embodiment 2

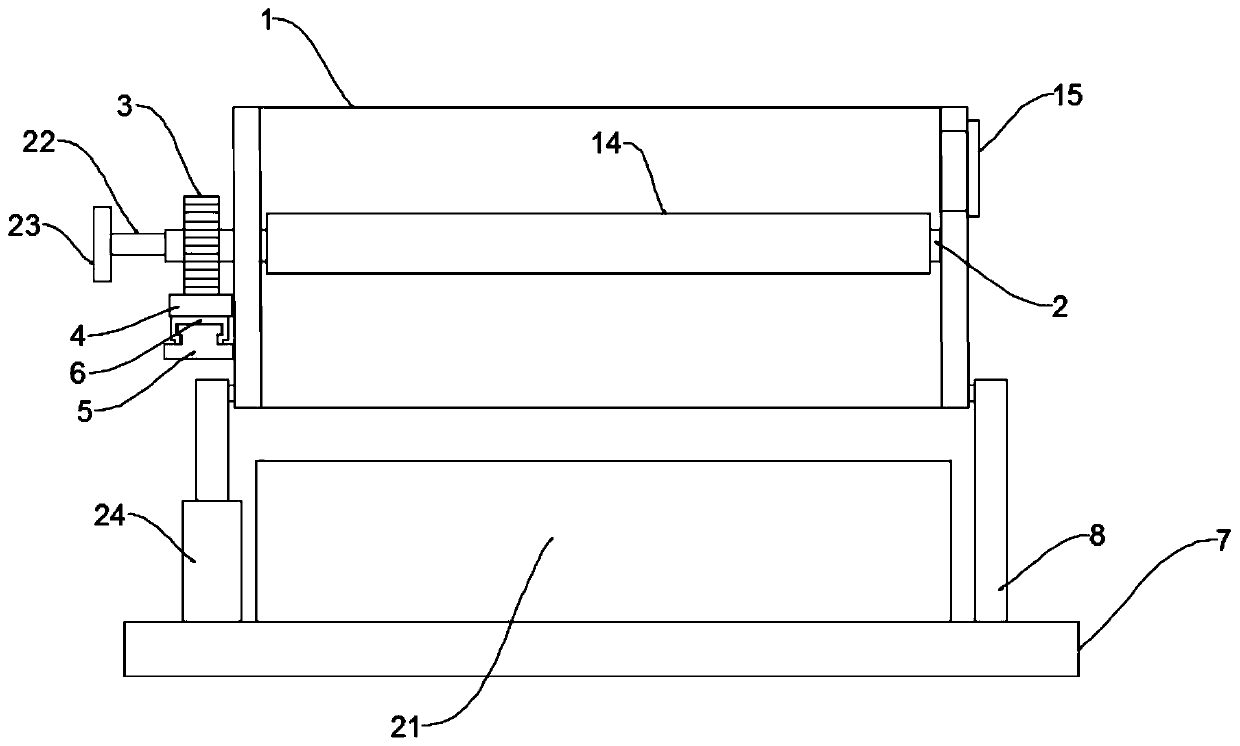

[0029] The difference between the embodiment of the present invention and embodiment 1 is that a spiral sleeve 16 is provided on the side wall of the screening channel 1 away from the drive gear 3, and the bottom edge of the spiral sleeve 16 is located at the top wall of the baffle plate 14. On the same plane, one end of the bottom wall of the screening channel 1 is hinged to the upper end surface of the screening channel 1 through a support frame 8, and the other end of the bottom wall of the screening channel 1 is provided with a hydraulic cylinder 24. When the hydraulic cylinder 24 is activated, it can One end of the screening channel 1 is raised, and then the arc plate 15 is opened, so that the stones stranded on the baffle plate 14 are released from the arc plate 15, and it is more convenient to discharge the stones.

[0030] The upper end surface of the base plate 7 is also provided with a collecting tank 21 located directly below the screening channel 1 to facilitate the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com