Full-automatic mobile phone screen assembling device

A mobile phone screen and assembly device technology, which is applied in hand-held tools, telephone structure, telephone communication, etc., can solve the problems of low production efficiency, high labor intensity of workers, misoperation, etc., and achieve the goal of improving production efficiency and improving production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

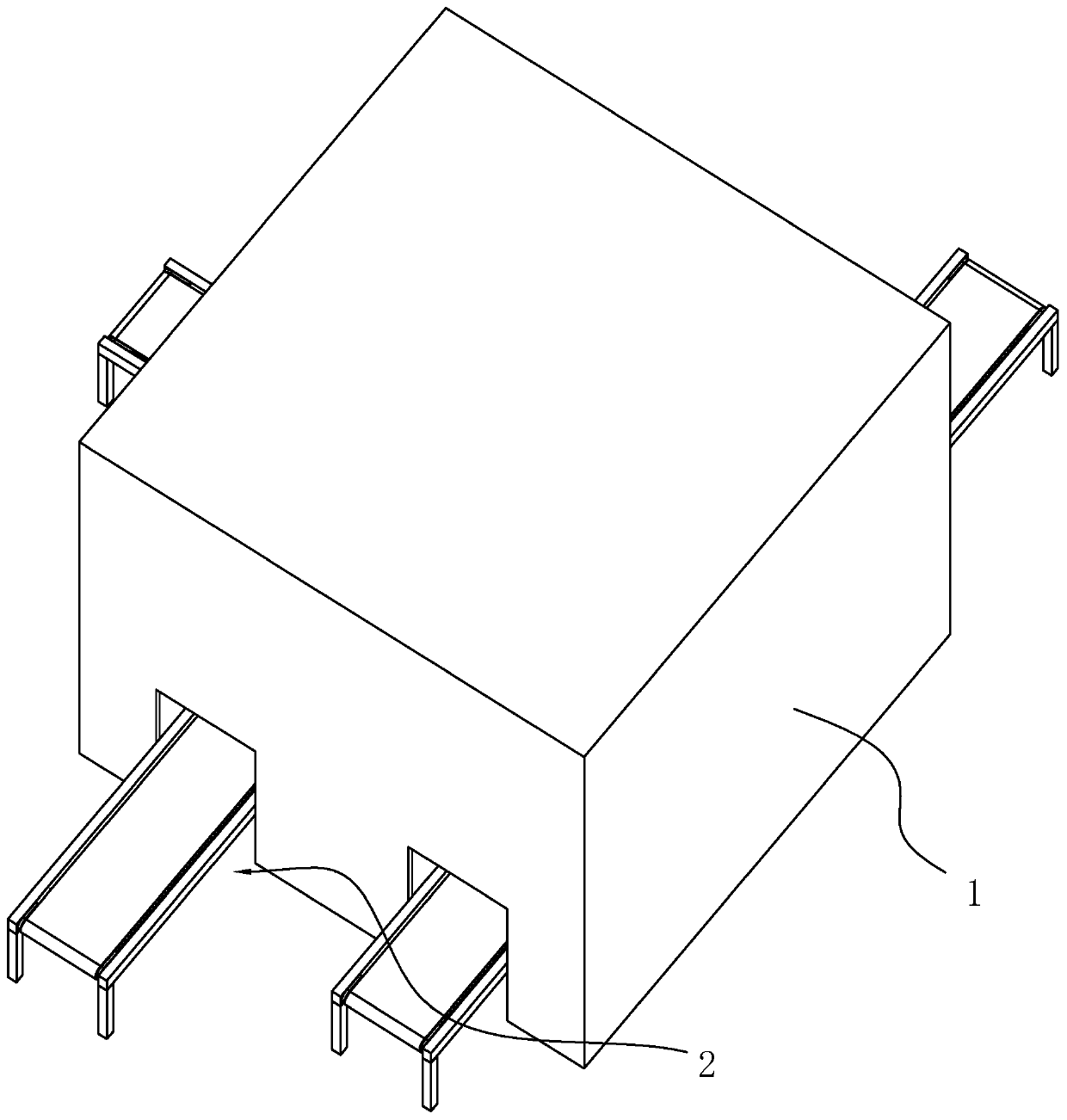

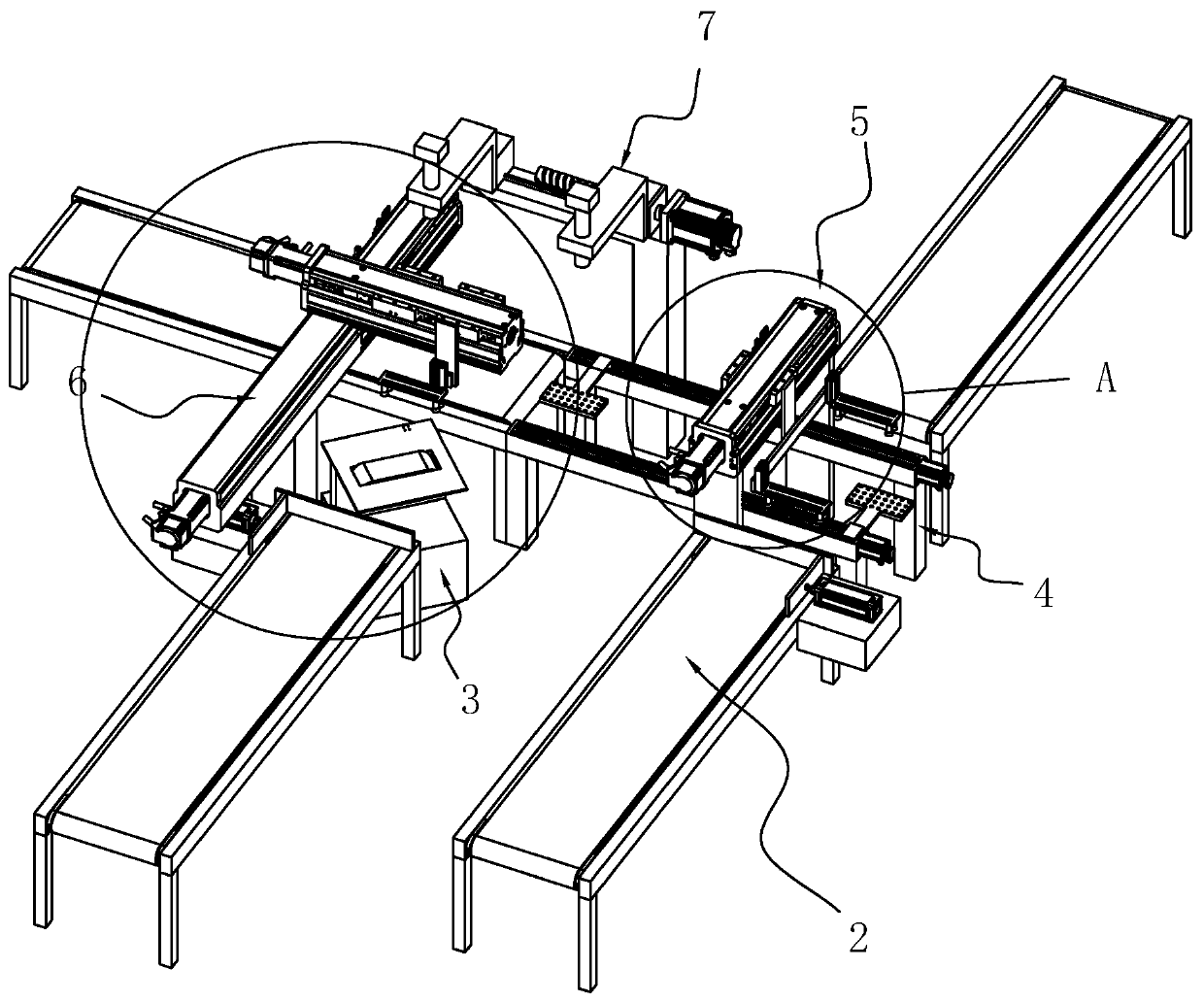

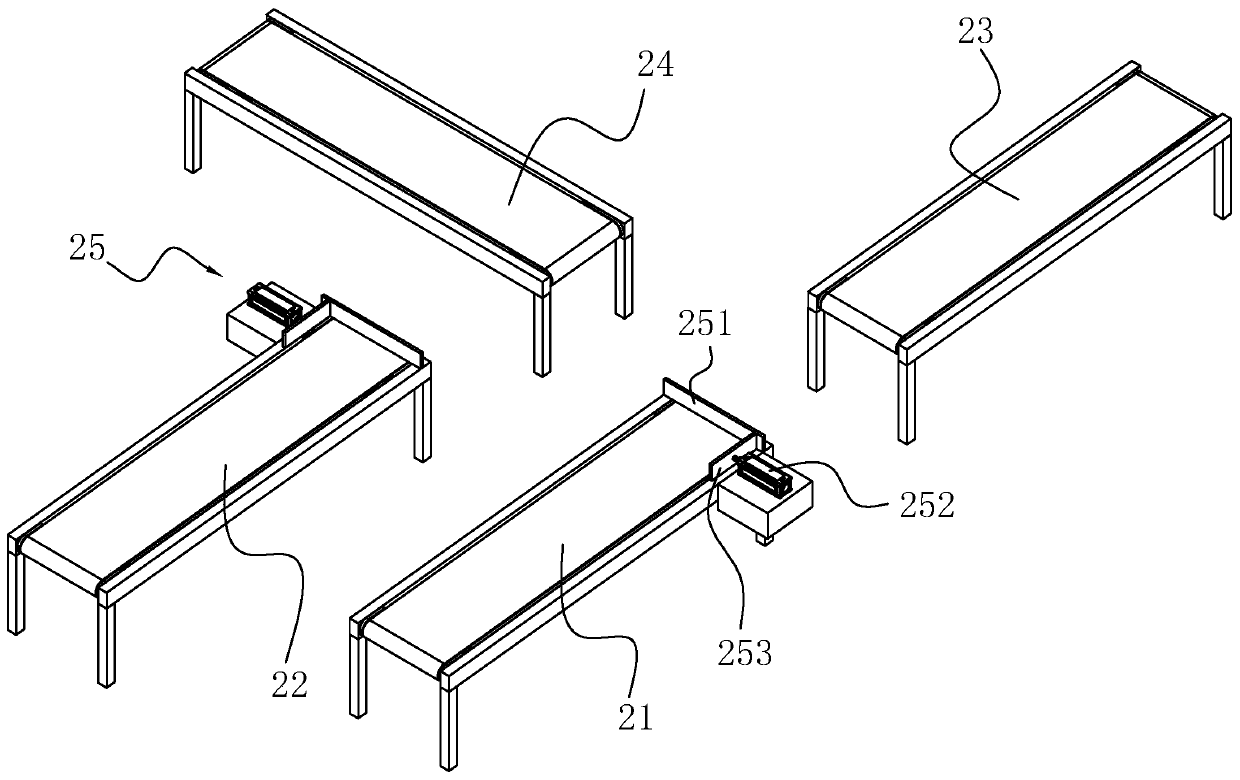

[0042] A fully automatic mobile phone screen assembly device, combined with figure 1 and figure 2 As shown, it includes a conveying assembly 2 for intermittently conveying various parts and can convey finished products, a release film tearing assembly 3 for tearing off the release film attached to the tempered glass surface, and a transfer Tooling assembly 4 for display modules and finished products, first pick-and-place manipulator assembly 5 for pick-and-place display modules and finished products, second pick-and-place manipulator assembly 6 for pick-and-place tempered glass, and inspection of finished products Component 7; wherein, it also includes a dust cover 1 that covers the above-mentioned components to prevent dust intrusion, and the input ends of the components, the output end of the finished product and the output end of the waste produc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com