Automatic packaging production line for canned ink

An automated production line and ink technology, applied in the directions of automatic packaging control, packaging, packaging protection, etc., can solve the problems of ink filling efficiency reduction and achieve the effect of filling market vacancies

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

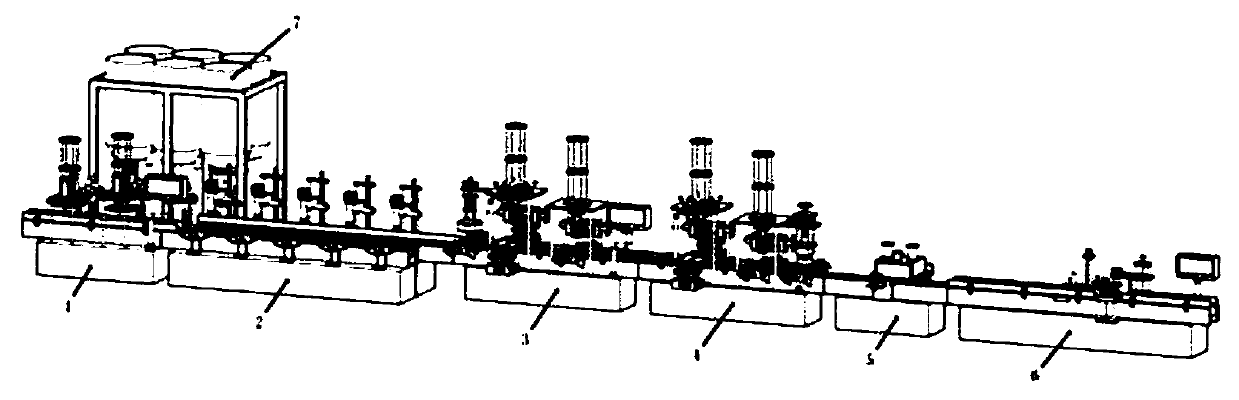

[0075] A kind of packing automatic production line of canned ink of the present invention, structure is as follows figure 1 As shown, it includes a tank drop section 1, a filling section 2, a film drop cover I section 3, a film drop cover II section 4, a vacuum section 5, a label section 6 and an ink storage tank 7 arranged in sequence.

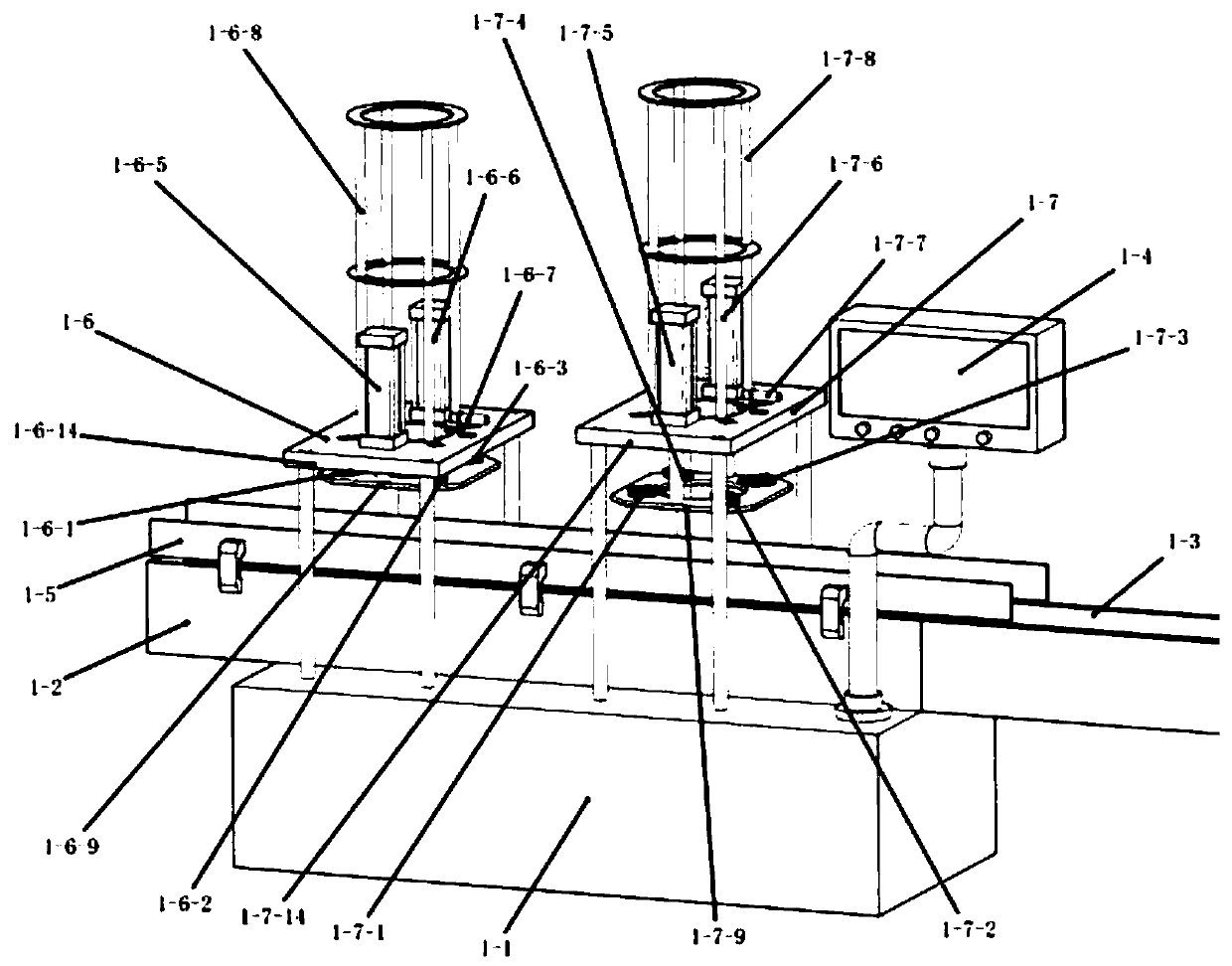

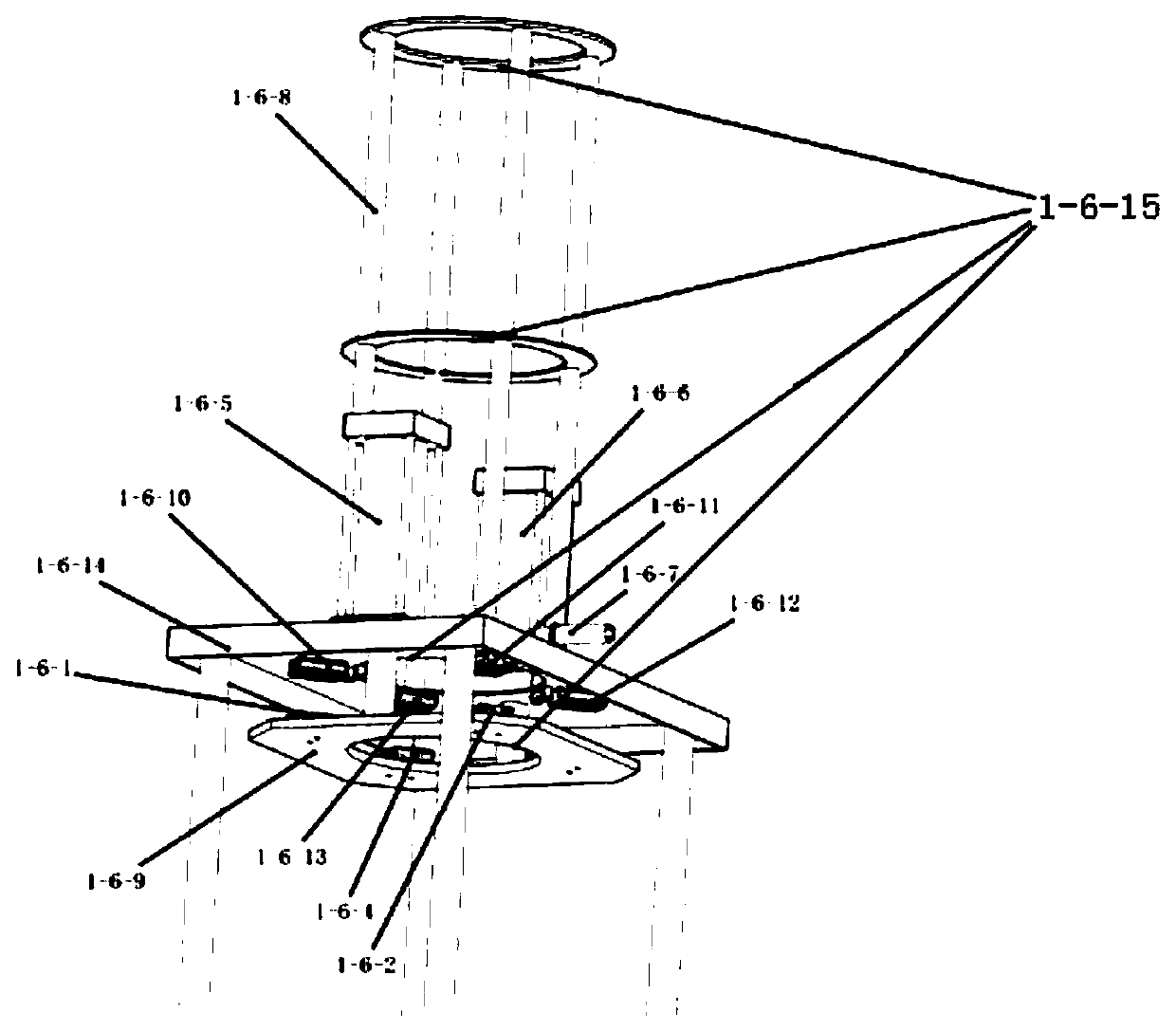

[0076] Such as figure 2 As shown, the can falling part 1 includes a can falling part frame 1-1, a can falling part conveying rack 1-2 is arranged above the can falling part frame 1-1, and a tank falling part conveying frame 1-2 is arranged side by side directly above 1-6 and 2.5 kg tank racks 1-7, the opposite sides of the upper end of the tank transport frame 1-2 are respectively provided with tank baffles 1-5 to limit ink The path of the cans; the cans falling part conveyor frame 1-2 is also provided with a cans falling part conveyor belt 1-3, and the cans falling part conveyor belt 1-3 is located between the two cans falling part retaini...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com