Optical component, manufacturing method thereof, bonding method, and display device

A technology for optical components and optical adhesive layers, which can be used in bonding methods, chemical instruments and methods, identification devices, etc., and can solve problems such as low bonding accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

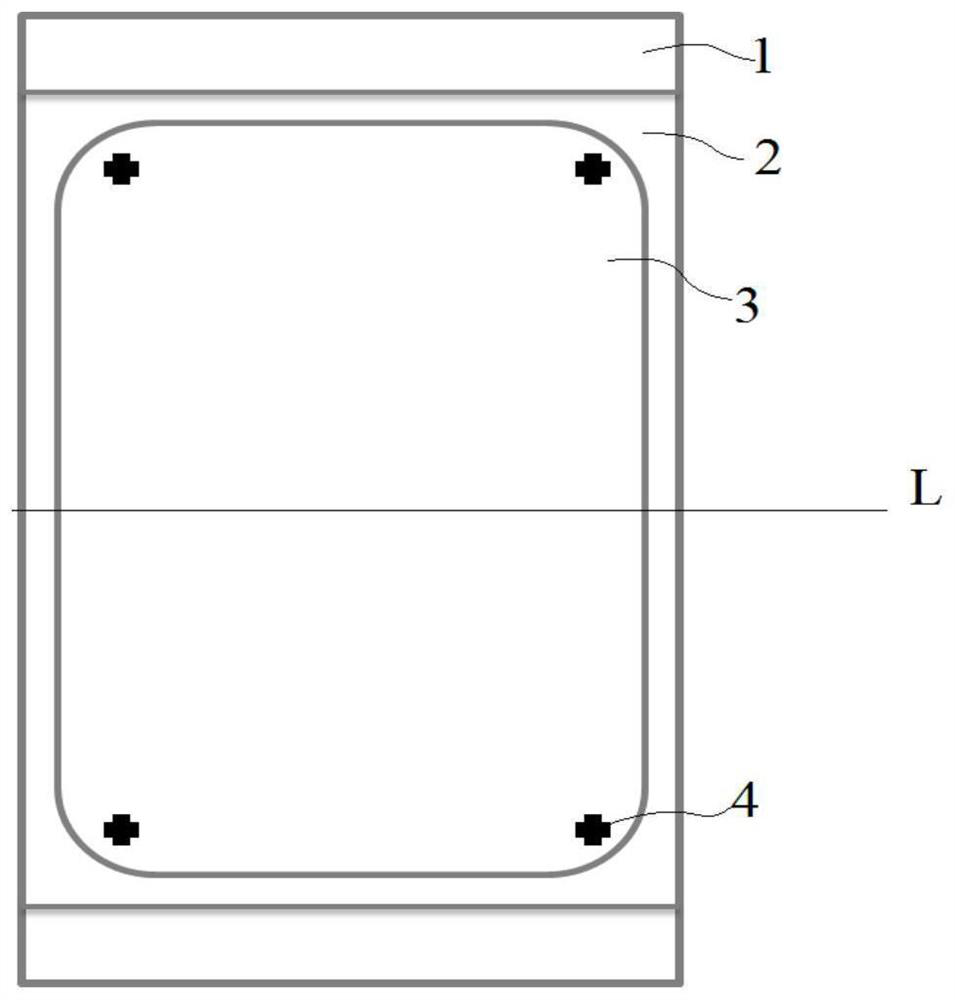

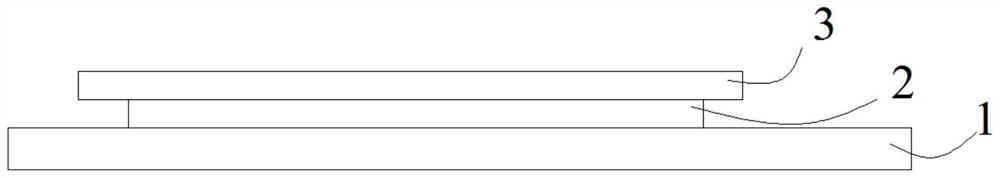

[0021] combine figure 1 and figure 2 , the present embodiment provides an optical assembly, including a stacked first release film 1, an optical adhesive layer 2, and a second release film 3, on the surface of the optical adhesive layer 2 facing away from the first release film 1 At least one alignment mark 4 is also provided, and the material of the alignment mark 4 includes an up-conversion luminescent material, which can convert infrared light into visible light.

[0022] If the first release film 1 is a heavy release film, the second release film 3 is a light release film. If the first release film 1 is a light release film, the second release film 3 is a heavy release film. In the above solution, the alignment mark 4 is made on the optical adhesive layer 2, or it is made on the heavy release film as in the prior art. Of course, the alignment mark 4 can be made on the surface of the optical adhesive layer 2 facing the heavy release film, or on the surface of the optica...

Embodiment 2

[0030] combine figure 1 and figure 2 , this embodiment provides a method for manufacturing an optical component, including the following steps.

[0031] In step S1, an optical adhesive layer 2 attached with a first release film 1 is provided.

[0032] In step S2, at least one alignment mark 4 is formed on the surface of the optical adhesive layer 2 facing away from the first release film 1, the material of the alignment mark 4 includes an up-conversion luminescent material, and the up-conversion luminescent material can convert infrared light for visible light.

[0033] Of course, an up-conversion luminescent material needs to be prepared. The above conversion luminescent material is NaGdF4:Er3 + Nanoparticles are taken as an example.

[0034] First, the Er(NO 3 ) 3 , Yb(NO 3 ) 3 and Gd(NO 3 ) 3 (The above three are usually in powder form or dissolved in solution) into deionized water, and at the same time add ethylenediaminetetraacetic acid (EDTA, usually in powde...

Embodiment 3

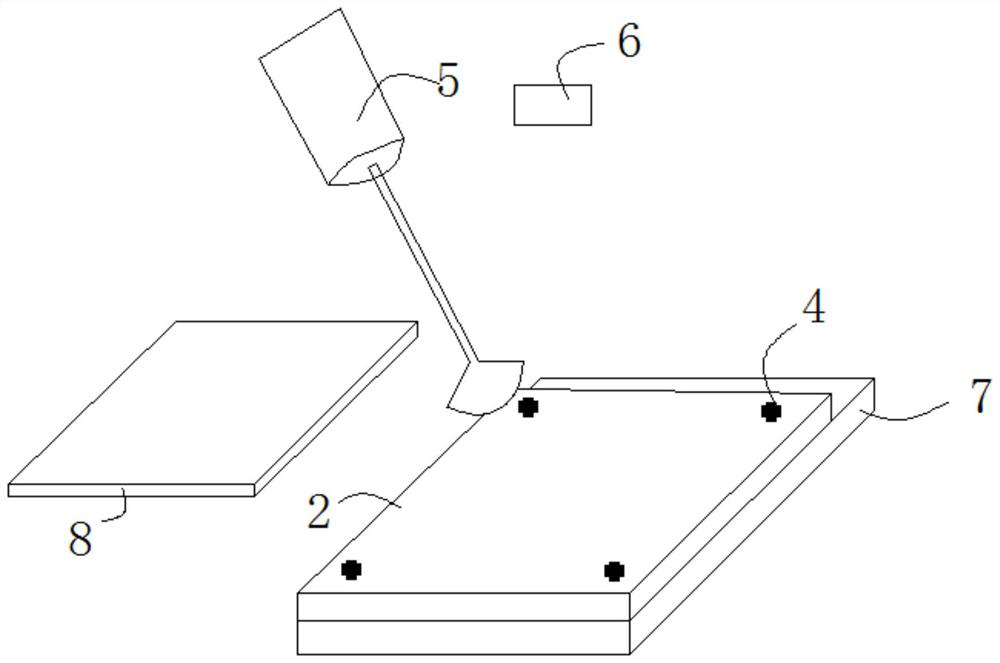

[0039] combine Figure 1-3 , this embodiment provides a bonding method, using the above-mentioned optical components for bonding, the bonding method includes: using infrared light to irradiate the area on the optical adhesive layer 2 provided with alignment marks, and using the identification device 6 to identify the area Shoot to achieve alignment.

[0040]The lamination of the display panel and the touch panel through the optical component is still taken as an example for illustration. That is, the first substrate 7 is the substrate to be bonded on the touch panel. The second substrate 8 is the substrate to be bonded on the display panel. The detailed bonding process is as follows.

[0041] Tear off the light release film, use an infrared light source 5 to irradiate the area where the alignment mark 4 is set, and at the same time use a CCD to capture the alignment mark 4 on the optical adhesive layer 2 and capture the alignment mark 4 on the touch panel , and accordingly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com