Optical adhesive, manufacturing method thereof, bonding method and display device

A technology of optical glue and optical glue layer, which is applied in the field of display devices and optical glue, and can solve problems such as low lamination accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

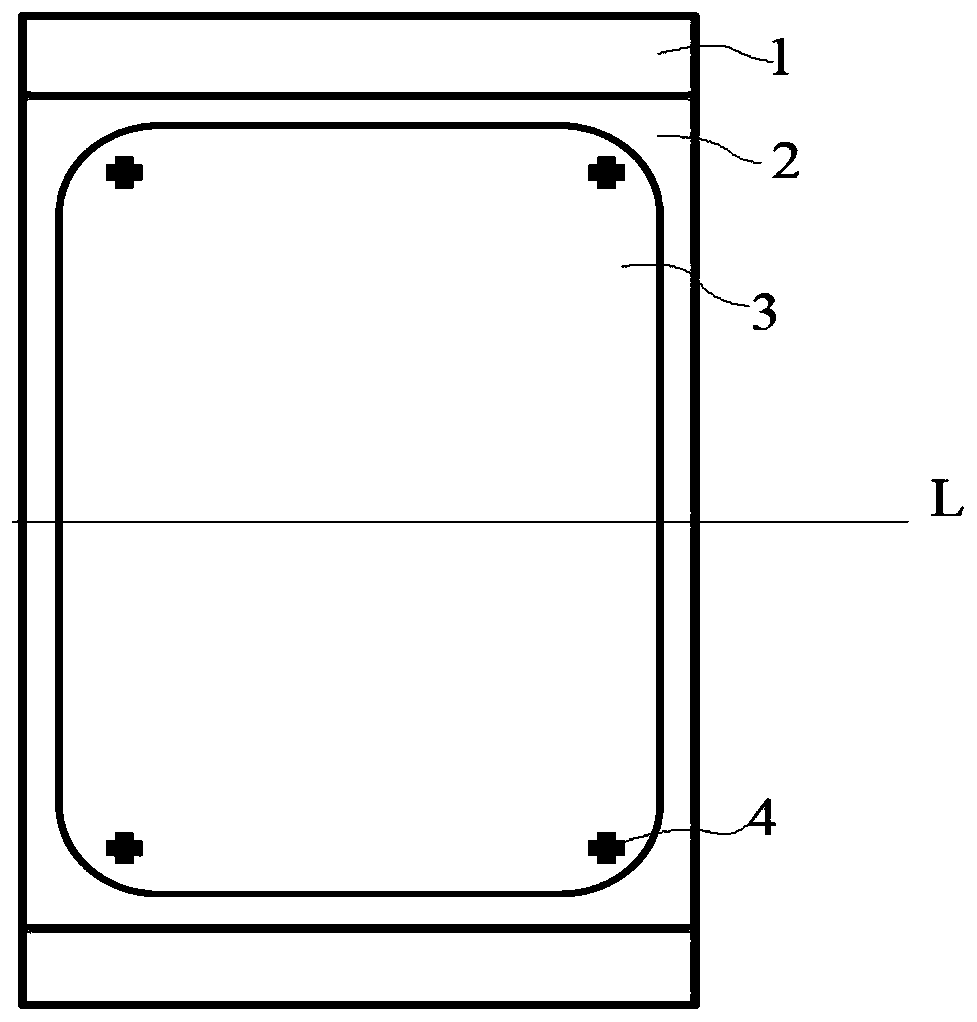

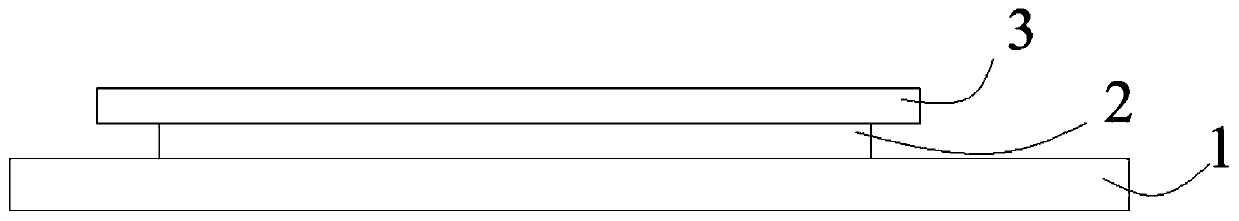

[0021] to combine figure 1 and figure 2 , the present embodiment provides an optical adhesive, including a stacked first release film 1, an optical adhesive layer 2, and a second release film 3, on the surface of the optical adhesive layer 2 facing away from the first release film 1 At least one alignment mark 4 is also provided, and the material of the alignment mark 4 includes an up-conversion luminescent material, which can convert infrared light into visible light.

[0022] If the first release film 1 is a heavy release film, the second release film 3 is a light release film. If the first release film 1 is a light release film, the second release film 3 is a heavy release film. In the above solution, the alignment mark 4 is made on the optical adhesive layer 2, or it is made on the heavy release film as in the prior art. Of course, the alignment mark 4 can be made on the surface of the optical adhesive layer 2 facing the heavy release film, or on the surface of the opt...

Embodiment 2

[0030] to combine figure 1 and figure 2 , the present embodiment provides a method for manufacturing optical glue, including the following steps.

[0031] In step S1, an optical adhesive layer 2 attached with a first release film 1 is provided.

[0032] In step S2, at least one alignment mark 4 is formed on the surface of the optical adhesive layer 2 facing away from the first release film 1, the material of the alignment mark 4 includes an up-conversion luminescent material, and the up-conversion luminescent material can convert infrared light for visible light.

[0033] Of course, an up-conversion luminescent material needs to be prepared. The above conversion luminescent material is NaGdF4:Er3 + Nanoparticles are taken as an example.

[0034] First, the Er(NO 3 ) 3 , Yb(NO 3 ) 3 and Gd(NO 3 ) 3 (The above three are usually in powder form or dissolved in solution) into deionized water, and at the same time add ethylenediaminetetraacetic acid (EDTA, usually in pow...

Embodiment 3

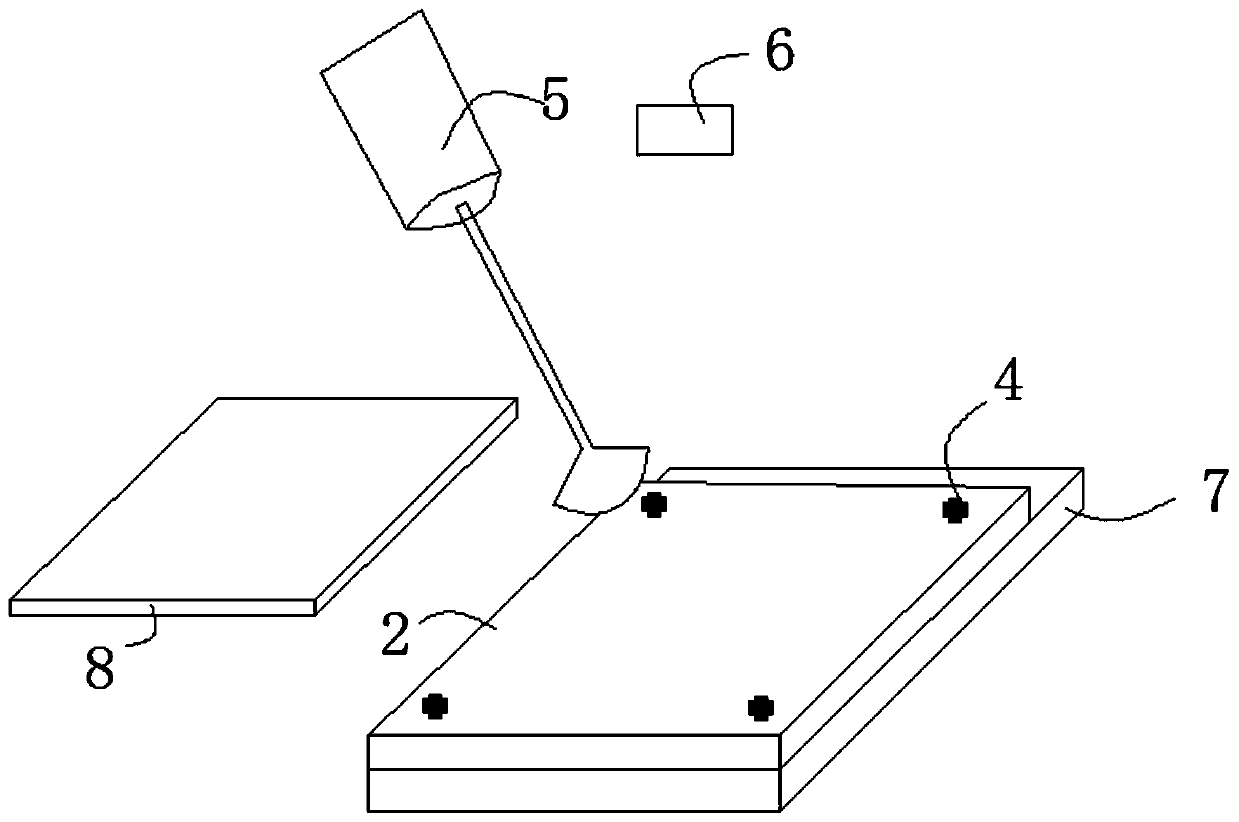

[0039] to combine Figure 1-3 , the present embodiment provides a bonding method, using the above-mentioned optical glue for bonding, the bonding method includes: using infrared light to irradiate the area on the optical adhesive layer 2 provided with a contrast mark, and using the identification device 6 to identify the area Shoot for alignment.

[0040] The lamination of the display panel and the touch panel by optical glue is still taken as an example for illustration. That is, the first substrate 7 is the substrate to be bonded on the touch panel. The second substrate 8 is the substrate to be bonded on the display panel. The detailed bonding process is as follows.

[0041] Tear off the light release film, use an infrared light source 5 to irradiate the area where the alignment mark 4 is set, and at the same time use a CCD to capture the alignment mark 4 on the optical adhesive layer 2 and capture the alignment mark 4 on the touch panel , and accordingly attach the optica...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com