A bottom blowing air supply component installation method

A technology of gas supply components and installation methods, applied in the metallurgical field, can solve problems such as affecting the arrangement of security measures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

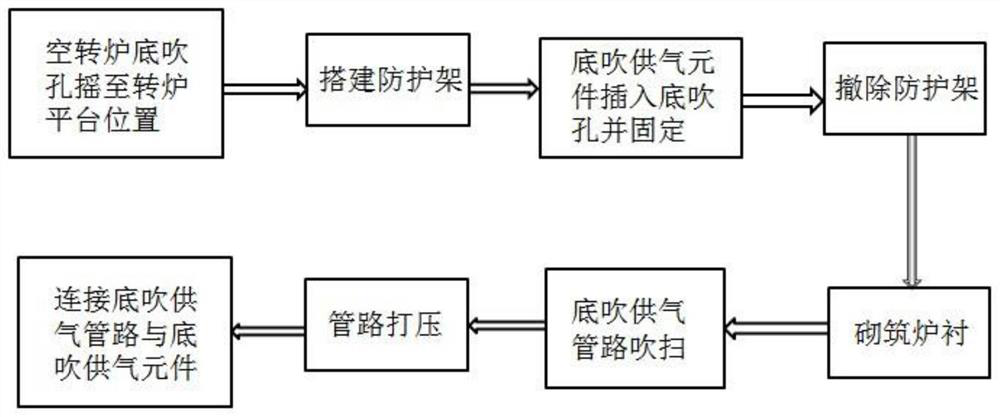

[0074] The installation method of the annular seam bottom blowing air supply element includes the following steps:

[0075] (1) Shake the blowing hole at the bottom of the empty rotary furnace to be built to the position facing the converter platform;

[0076] (2) Build a protective frame from the converter platform to the converter bottom of step (1);

[0077] (3) Insert the bottom blowing gas supply element into the blowing hole at the bottom of the converter through the protective frame described in step (2) and fix it;

[0078] (4) Remove the protective frame built in step (2);

[0079] (5) Shake the furnace to the 0 position, and start to build the furnace lining;

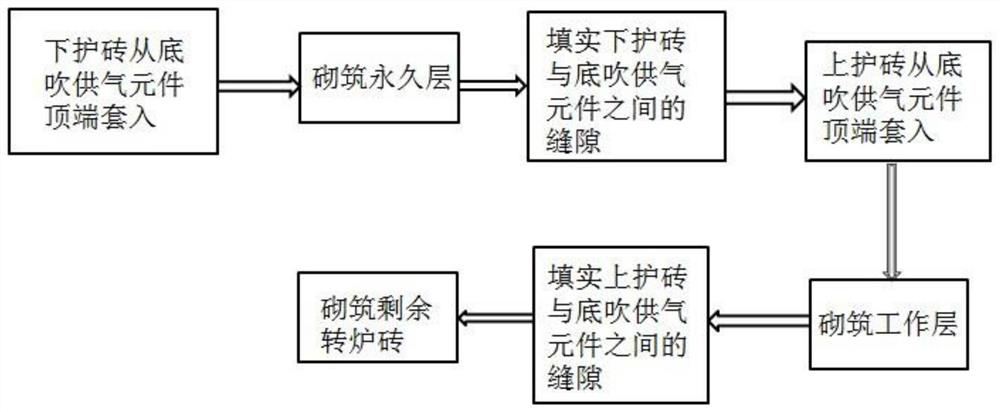

[0080] (6) Insert the lower protective brick from the top of the bottom blowing gas supply element, and fit it with the furnace shell;

[0081] (7) Permanent layer masonry at the bottom of the converter;

[0082] (8) Fill the gap between the lower protective brick and the bottom blowing air supply element ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com