Oil filter net mounting structure and integrated stove

An installation structure and oil filter technology, which can be applied to household stoves, oil fume removal, household stoves/stoves, etc., can solve problems such as troublesome cleaning, reduced air suction rate of oil filter, and affecting comfort in use, so as to achieve firm fixation, The effect of improving the overall structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

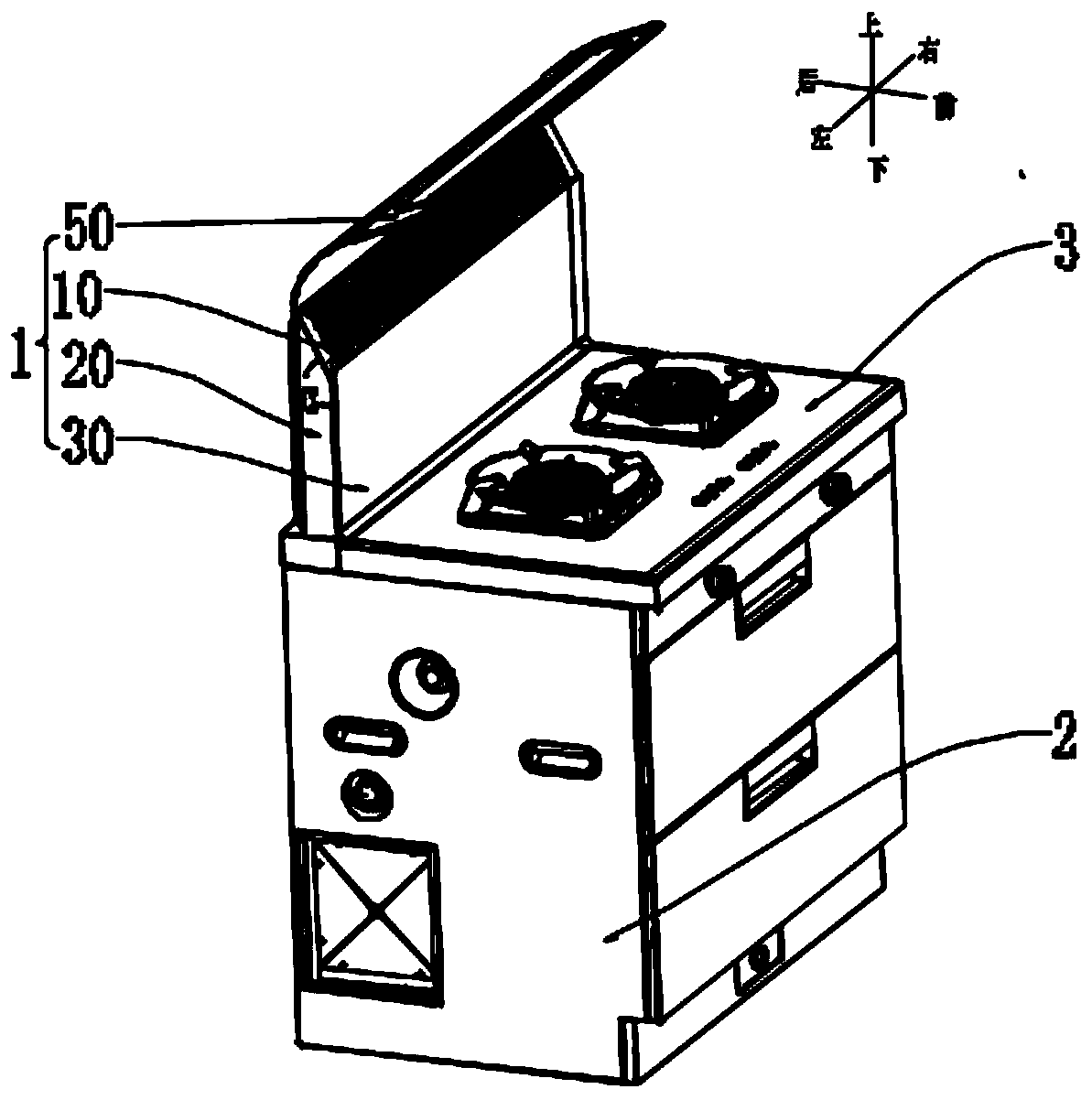

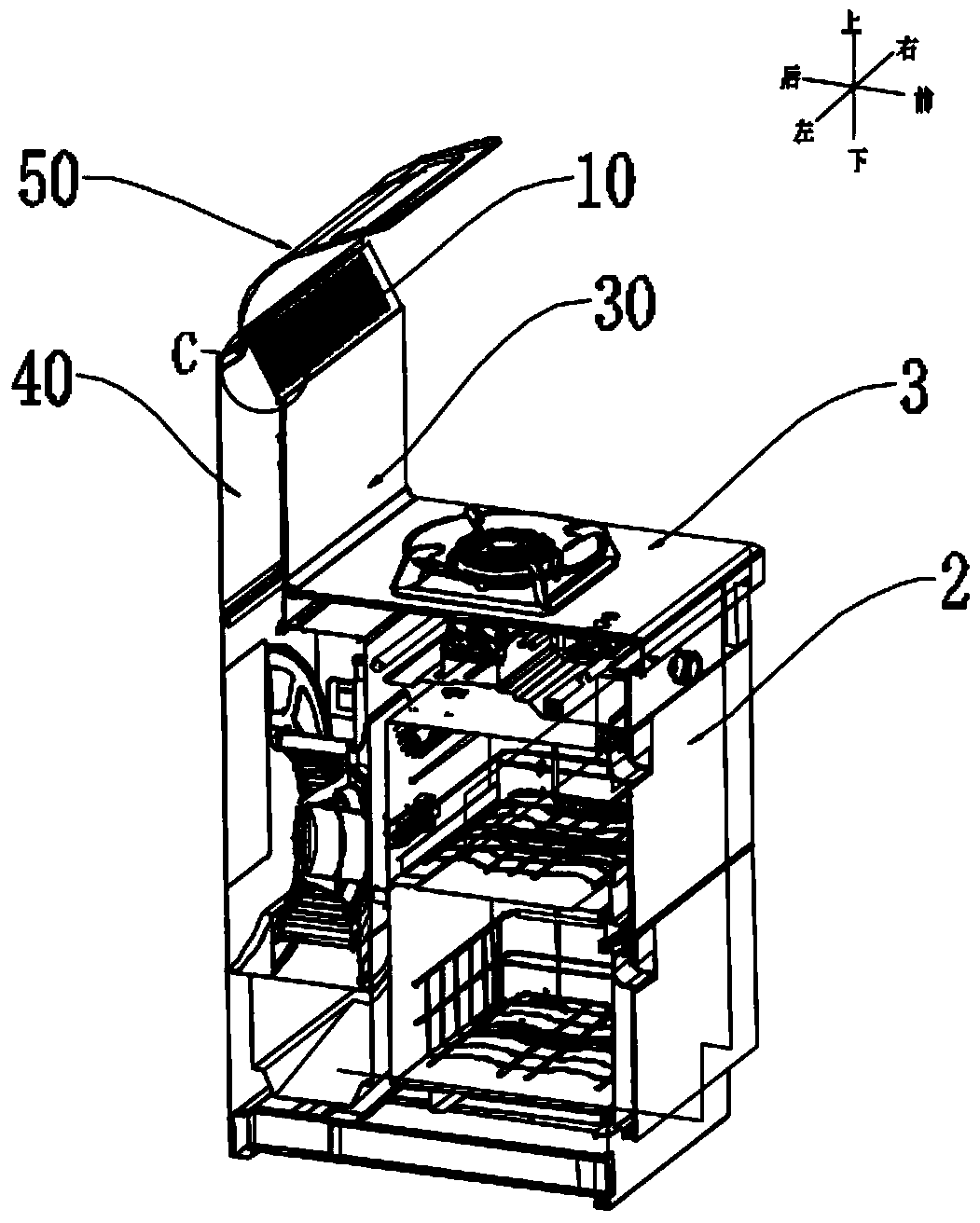

[0036] Such as figure 1 , figure 2 As shown, the integrated stove includes a box body 2, a stove 3 installed on the box body 2, a smoking hood 1 arranged above the stove 3, and a smoking channel connecting the box body 2 and the smoking hood 1, and the smoking channel includes a suction chamber And the air collection chamber, the suction chamber communicates with the air suction port on the smoke hood 1, wherein the smoke hood 1 includes a back plate 40, an arc-shaped top plate 50 positioned above the back plate 40, support columns 20 connected to both sides of the back plate 40, and an oil baffle 30 positioned on the front side of the support column 20 and an oil filter 10 positioned above the oil baffle 30. The oil baffle 30 is located at the rear of the cooktop 3 and is vertically connected with the cooktop 3. The back plate 40 and both sides The support column 20 and the oil baffle 30 together form a suction chamber, and the air suction port is located above the oil baff...

Embodiment 2

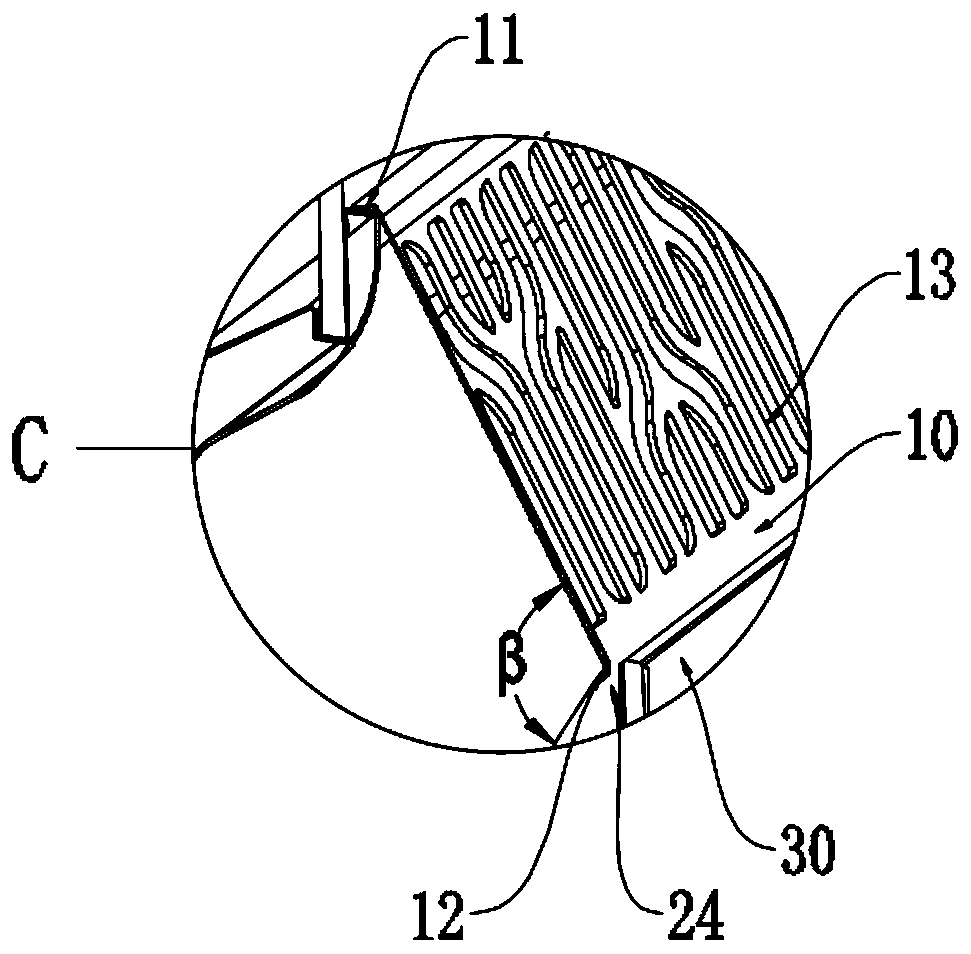

[0047] combine Figure 7 , Figure 8 , Figure 10 As shown, the difference between this embodiment and the above-mentioned embodiments is that the installation structure of the oil filter screen also includes the first folded edge 11 arranged on the upper side edge of the oil filter screen 10 and the first folded edge 11 arranged on the support column 20 Adapted limit surface 23, the limit surface 23 is connected with the side of the first connection surface 21 away from the second connection surface 22, the lower surfaces at both ends of the first folded edge 11 are respectively connected with the limit surfaces 23 on both sides of the air suction port fit.

[0048] Specifically, in order to play a position-limiting role, the position-limiting surface 23 is inclined relative to the first connection surface 21, and the position-limiting surface 23 is perpendicular to the backboard 40. Since the second connection surface 22 and the backplane 40 are both perpendicular to the c...

Embodiment 3

[0054] combine image 3 , Figure 4 As shown, the difference between this embodiment and the above-mentioned embodiments is that a second folded edge 12 is provided on the lower edge of the oil filter 10, and the second folded edge 12 is suitable for guiding the flow of oil.

[0055] Specifically, the second folded edge 12 is located in the middle of the lower edge of the oil filter screen 10, and is formed by folding the oil filter screen 10 inward along the lower edge, and the second folded edge 12 and the first folded edge 11 are located in the middle of the oil filter screen 10. Net 10 is on the same side. Preferably, the length of the second folded edge 12 is shorter than the length of the lower side of the oil filter screen 10, and the length of the second folded edge 12 is the same as the length of the air suction port. The width of the oil filter 10 corresponding to the second fold 12 is smaller than the width of the oil filter 10, that is, the bent second fold 12 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com