Vertical ultra low leakage probe card for DC parameter test

A probe card and probe technology, applied in the field of probe cards, can solve problems such as increasing manufacturing costs, and achieve the effects of preventing current leakage, reducing the number of electrical contacts, and reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] Hereinafter, preferred embodiments of the present invention will be described in detail. It should be understood, however, that the detailed description and specific examples, while indicating preferred embodiments of the invention, are illustrative only since various changes and modifications within the spirit and scope of the invention will be suggested to those skilled in the art from the detailed description. Personnel becomes apparent.

[0044] Also, the size and shape of components shown in the drawings referred to in the following detailed description may be exaggerated for convenience and conciseness of description.

[0045] In addition, the terms used herein are defined by considering the functions of the present invention, and may be changed according to user's or operator's habit or purpose. Therefore, definitions of terms should be made based on the entire disclosure set forth herein.

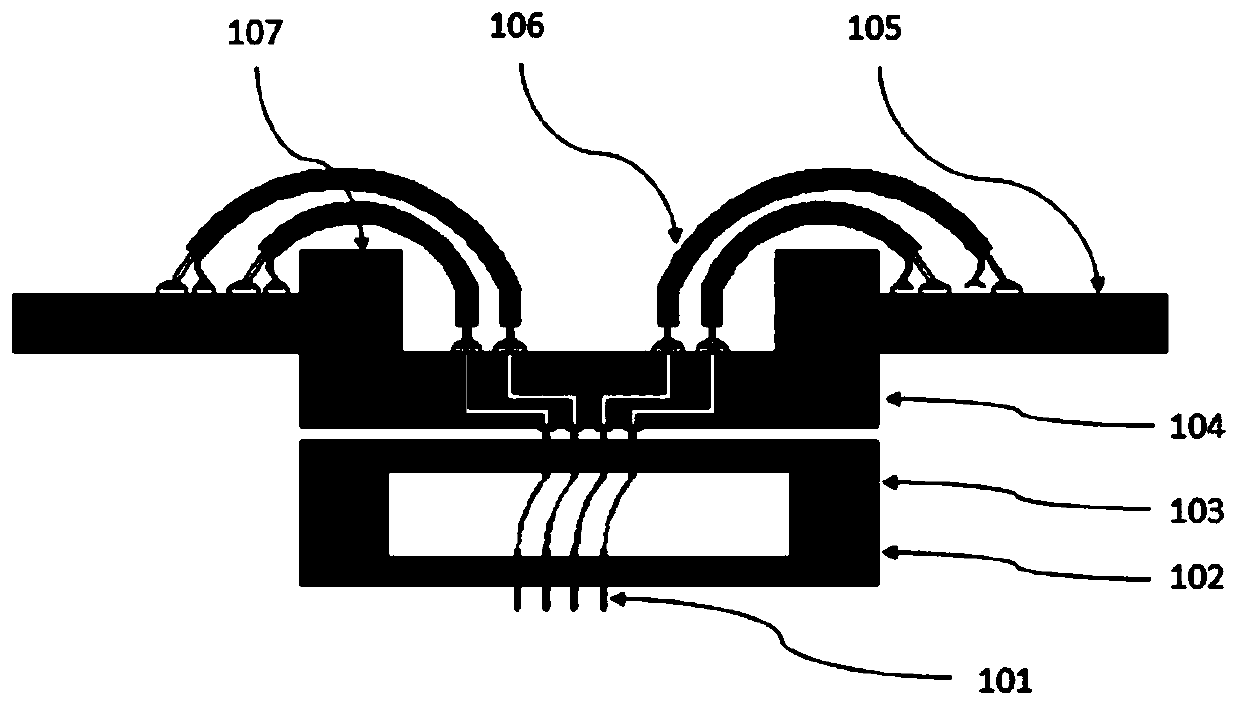

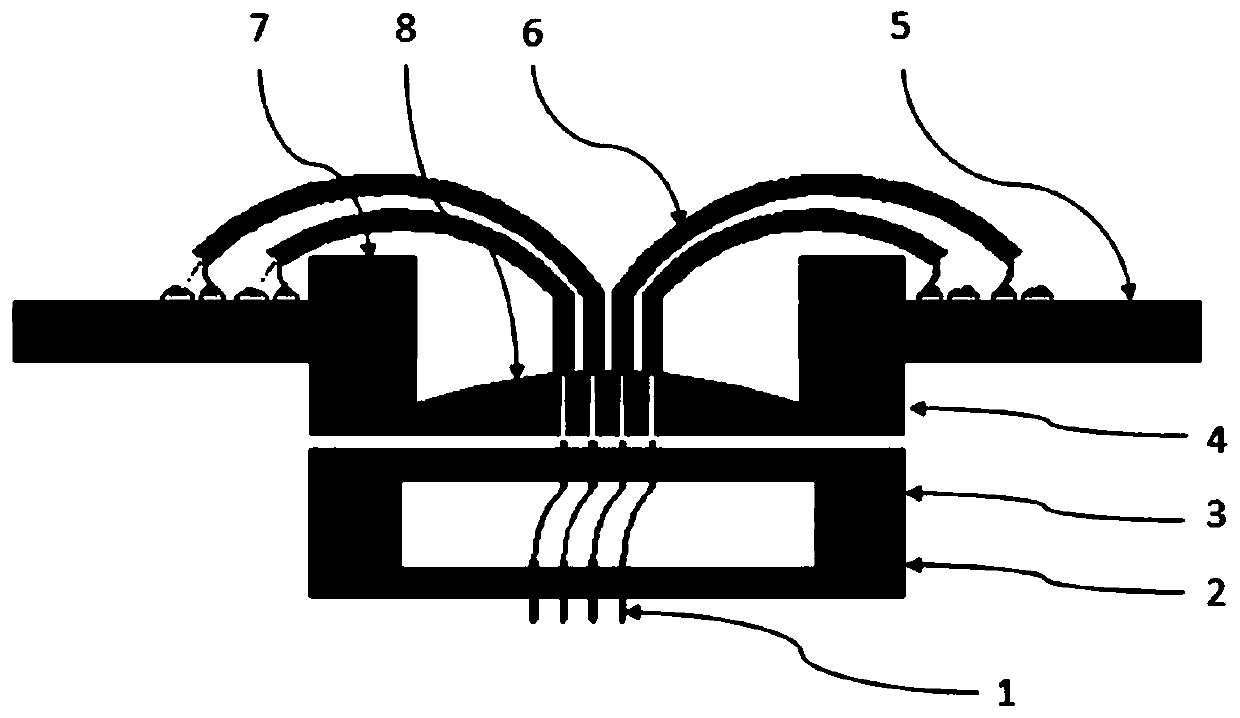

[0046] figure 2is a cross-sectional view showing the structure of a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com