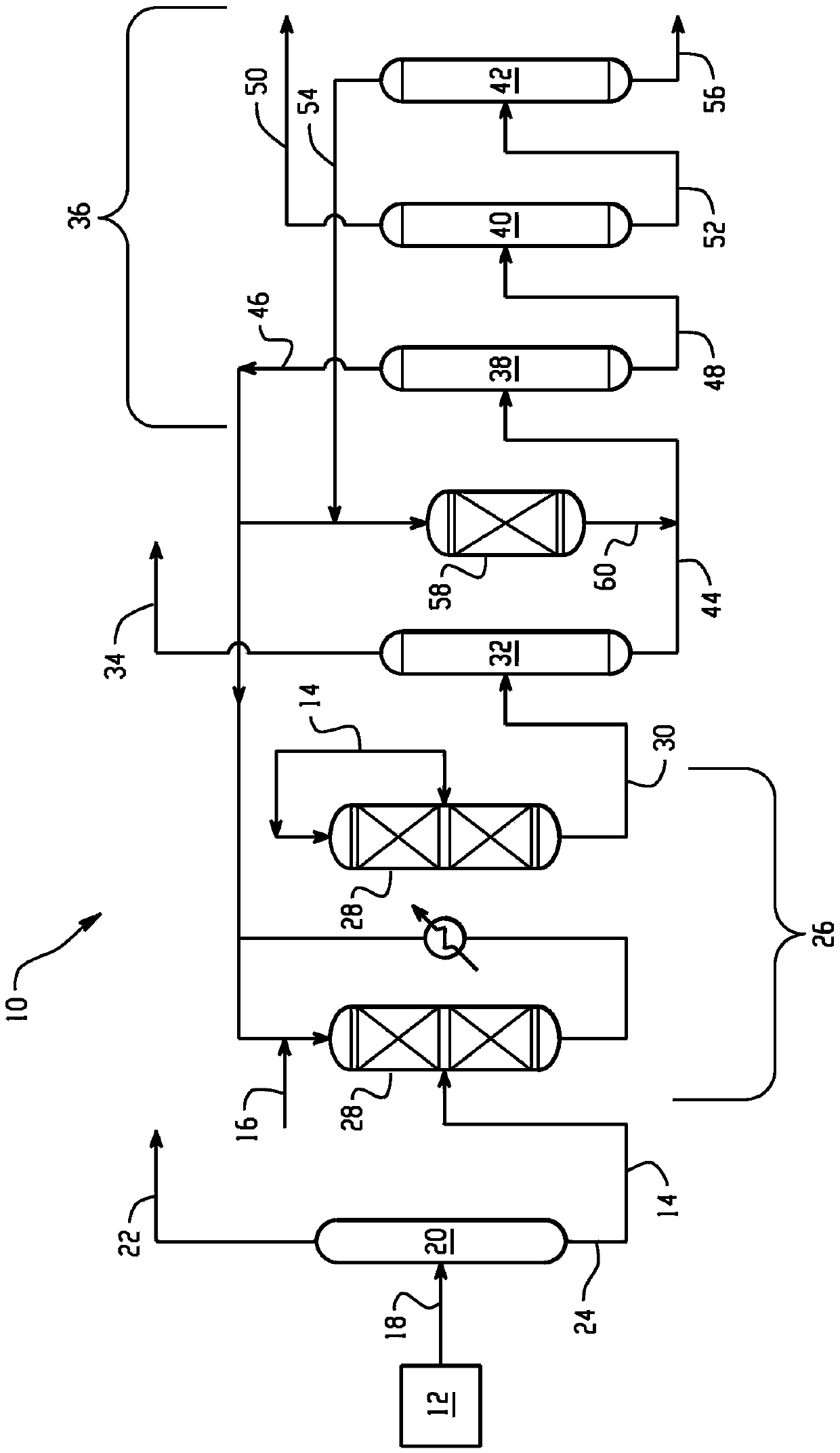

C3 fractionation system

A fractionation system and distillation tower technology, applied in the field of C3 fractionation system, can solve problems such as loss of propylene

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The term "C3" is understood herein as a hydrocarbon having 3 carbon atoms. In known C3 fractionation columns, the separation is performed with the aim of obtaining a bottom product in which the concentration of propylene is as low as possible. In the disclosed system, fractionation occurs by producing a relatively large amount of a propylene-depleted bottoms product, which results in a bottoms product containing relatively high amounts of propylene. The bottoms product is then used by the cumene production unit to produce cumene. By separating the feed in this way (increased bottoms), more feed can be processed while producing the same purity overhead using the same C3 fractionator. The system of the present disclosure may also allow for a higher purity overhead product to be obtained from the same feed, or to obtain an overhead product of the same purity using a feed having a lower concentration of propylene, without changing the C3 fractionator.

[0012] The bottoms...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com