Comprehensive improvement device for saline-alkali land

A technology of saline-alkali land and frame, which is applied in the direction of shovel, plow, and soil lifting machinery, etc. It can solve the problems of low degree of automation, reduce the efficiency of transformation construction, increase the difficulty of construction, etc., and achieve the effect of shortening the transformation time and improving the degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

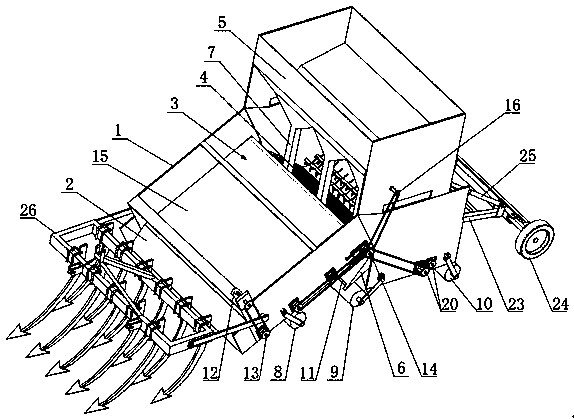

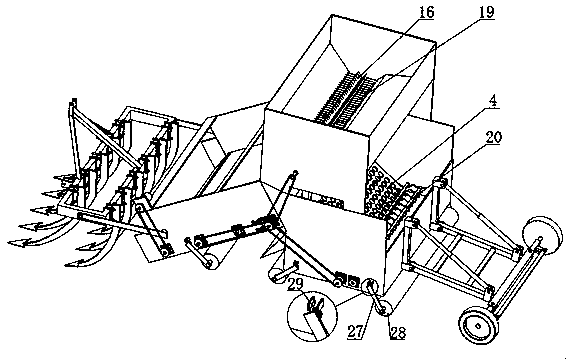

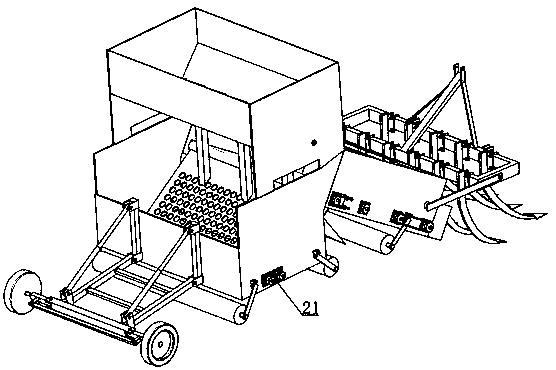

[0031] Below in conjunction with accompanying drawing, preferred embodiment of the present invention is described:

[0032] like Figures 1 to 8 As shown, a comprehensive improvement device for saline-alkali land includes a frame 1, a topsoil extraction mechanism, a topsoil backfill mechanism, a material addition mechanism, and a suppression mechanism; the frame 1 can be connected to agricultural traction equipment, such as an agricultural tractor, to realize this equipment The operation and walking of the topsoil extraction mechanism is used to dig the surface soil in the planting area and form a paving trough, so as to add materials for improvement; the topsoil backfilling mechanism is connected with the topsoil extraction mechanism, and passes through the topsoil backfilling mechanism after the topsoil is transported and lifted. Realize automatic soil covering; the material adding mechanism is used to add material between the surface soil extraction mechanism and the surfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com