Opening device for casting box of wear-resistant casting

A technology for castings and boxes, applied in the field of wear-resistant castings, can solve the problems of time-consuming, labor-intensive, etc., and achieve the effects of reasonable structural design, improved work efficiency, and high practical value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

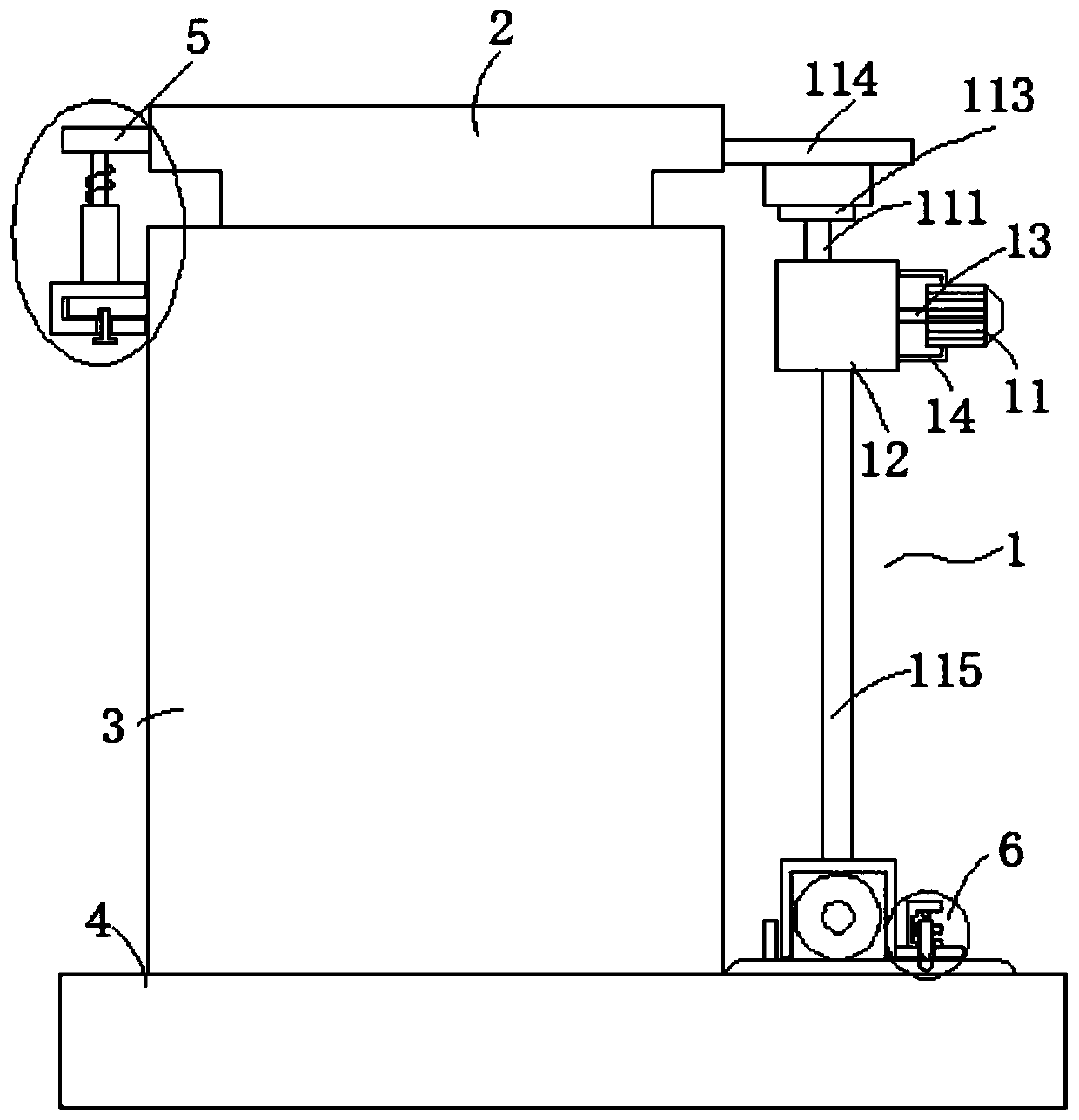

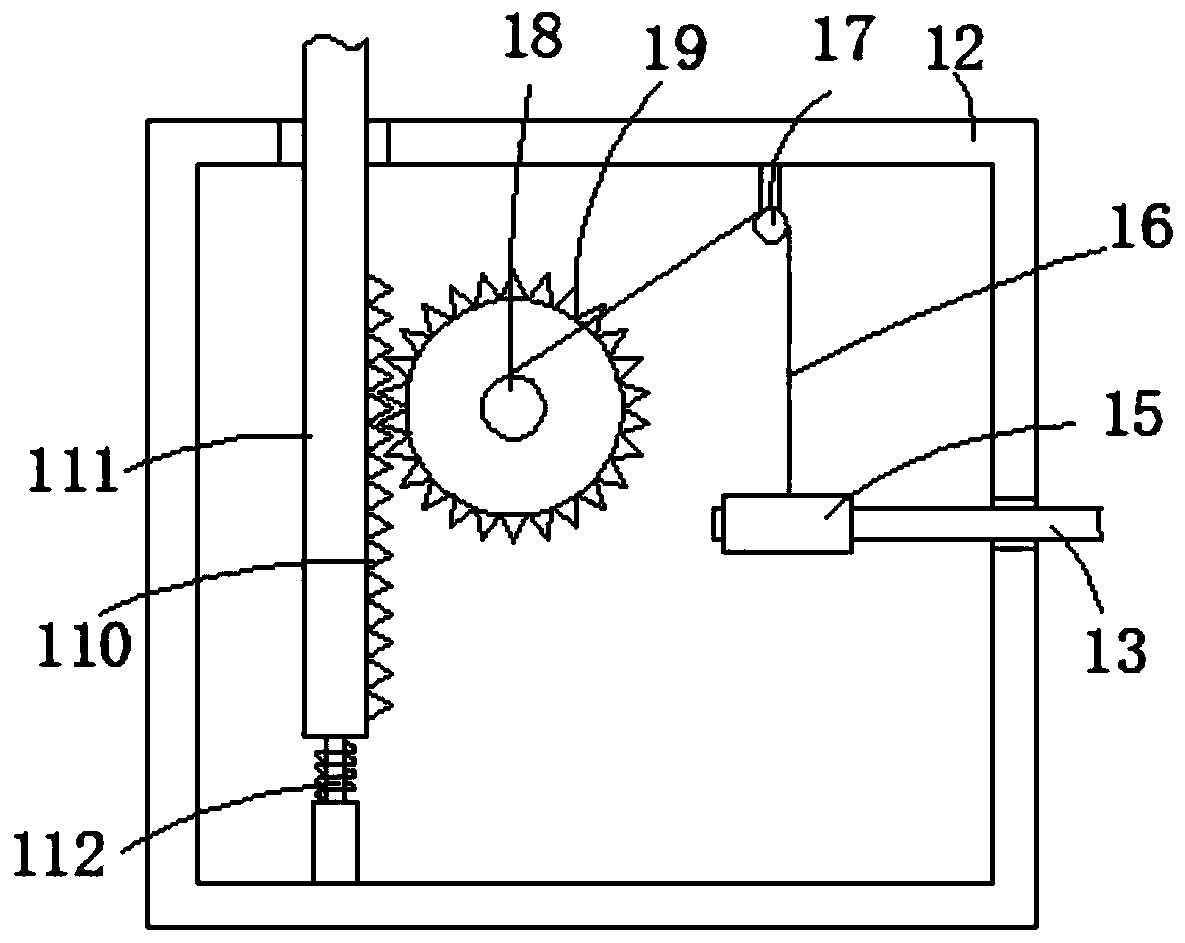

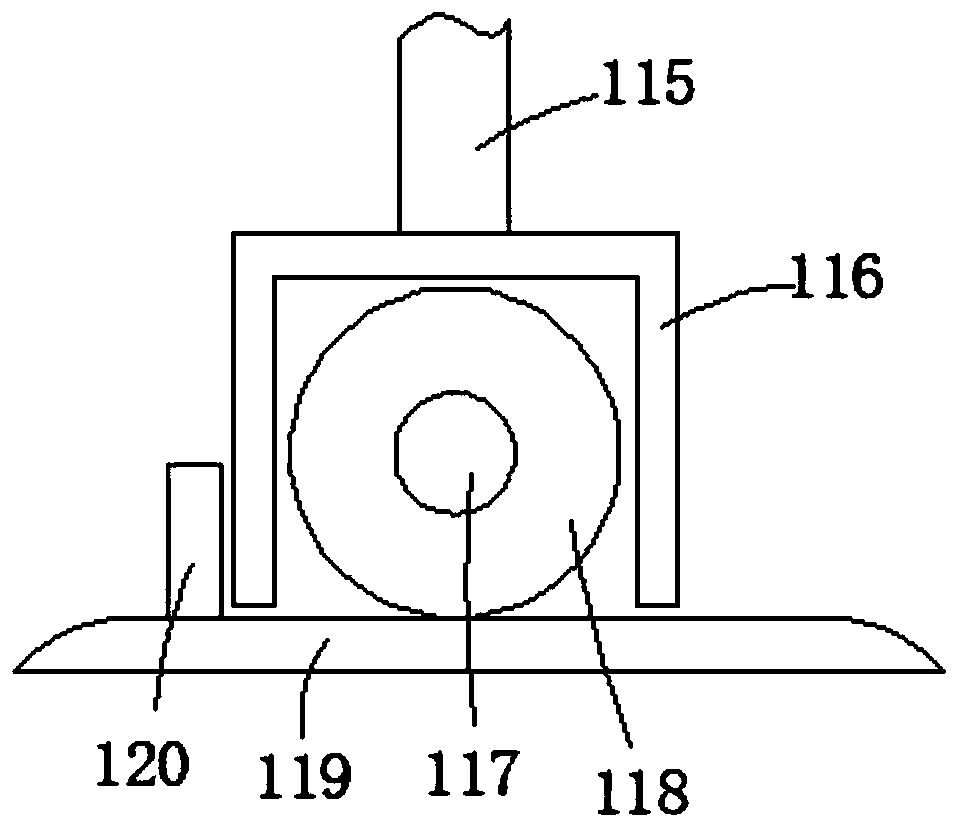

[0027] Attached below Figure 1-6 The present invention is further described with embodiment:

[0028] An opening device for a casting box of wear-resistant castings, comprising an opening device 1, the opening device 1 comprising a supporting plate 114 and a slide rail 119, the supporting plate 114 is fixedly arranged on the side plate of the box cover 2, And the case cover 2 is arranged on the case body 3, the case body 3 is fixedly arranged on the support base 4, the lower end of the support plate 114 is provided with a conflict block 113, and the lower end of the conflict block 113 is fixedly provided with a push rod 111, and the push rod 111 The lower end of the lower end moves through the top plate of the opening frame 12 and extends into the opening frame 12, and the lower end of the push rod 111 is fixedly provided with the first elastic telescopic rod 112, and the lower end of the first elastic telescopic rod 112 is fixedly arranged on the opening frame 12. On the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com