latch assembly

A technology of latches and components, applied to vehicle parts, transmissions, vehicle springs, etc., can solve problems such as high energy consumption and slow response time, achieve low production costs, prevent unintentional movement, and simple design effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

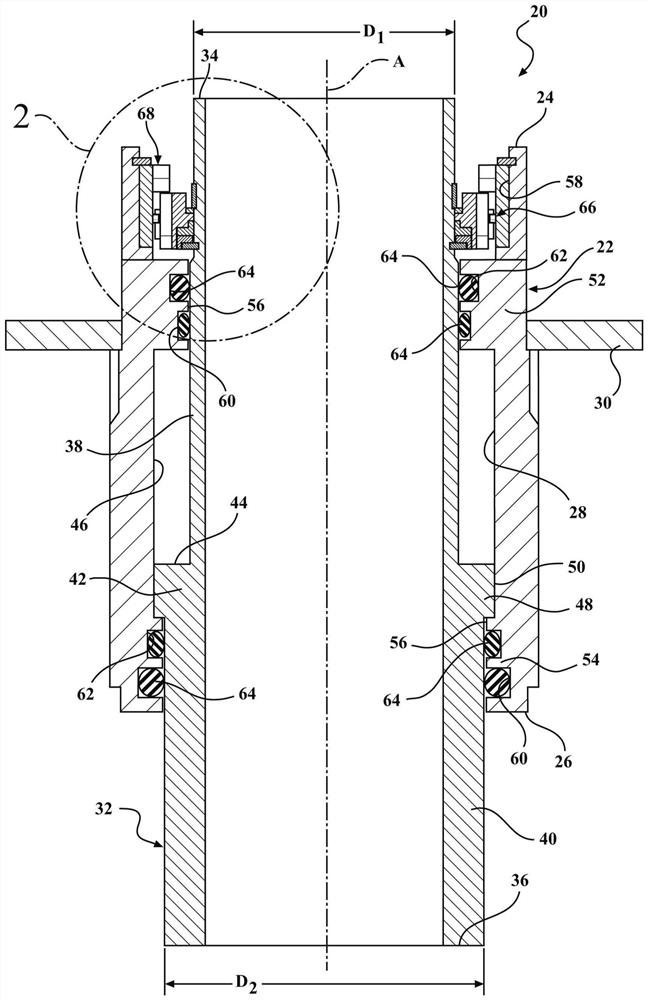

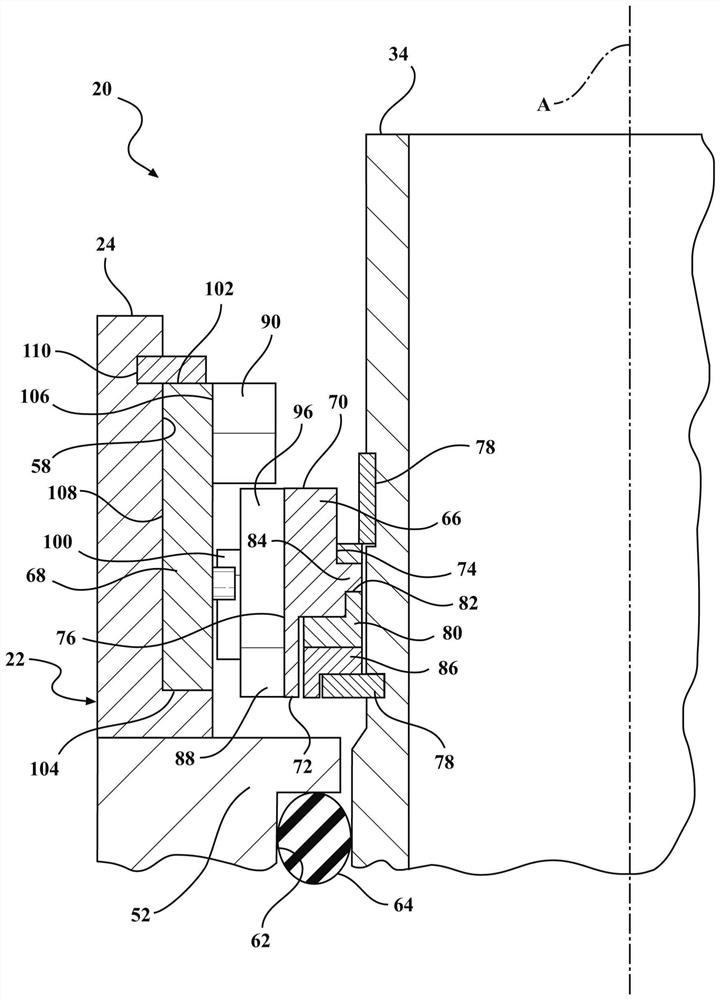

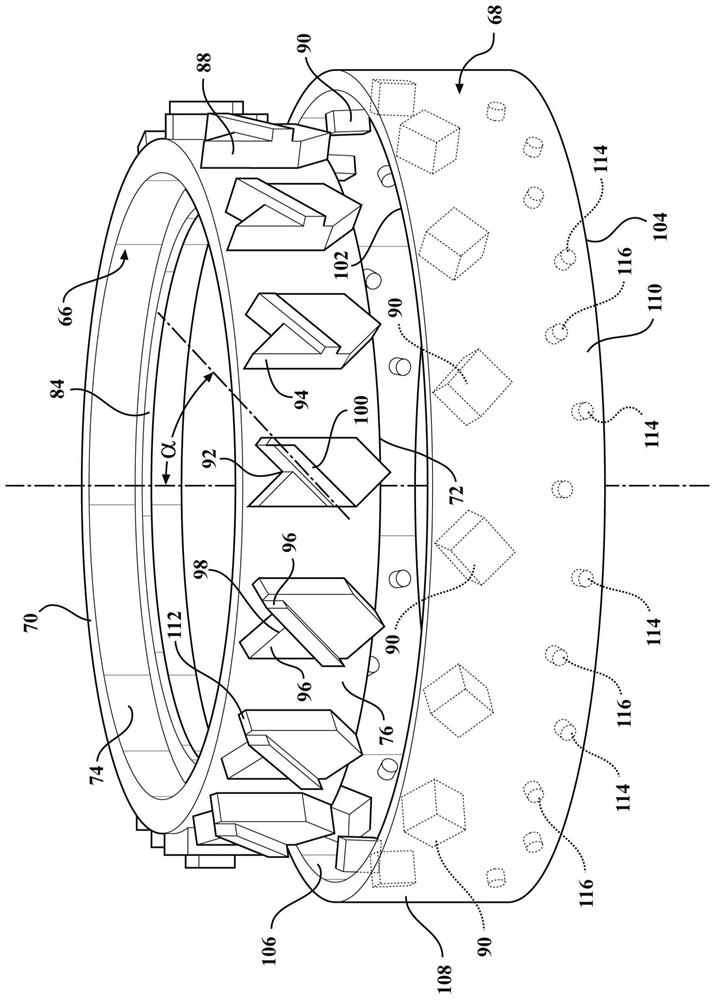

[0014] Referring to the drawings, wherein like reference numerals indicate corresponding parts throughout the several views, figure 1 A latch assembly 20 constructed in accordance with one embodiment of the present invention is generally shown in . Typically, the latch assembly 20 is used in vehicles to raise and lower the height of the vehicle.

[0015] refer to figure 1 The latch assembly 20 includes a lift housing 22 having a generally tubular shape annularly disposed about a central axis A and extending along the central axis A between a first open end 24 and a second open end 26 . Lift housing 22 defines a chamber 28 extending between first open end 24 and second open end 26 . A lift spring seat 30 is disposed about the first open end 24 , is attached to the lift housing 22 , and extends annularly about the central axis A. As shown in FIG. A support tube 32 having a generally cylindrical shape is slidably disposed in the chamber 28 . The support tube 32 is disposed in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com