Welding fume purifier

A technology of welding fumes and purifiers, which is applied to chemical instruments and methods, separation devices, and separation of dispersed particles. Large working space, compact structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

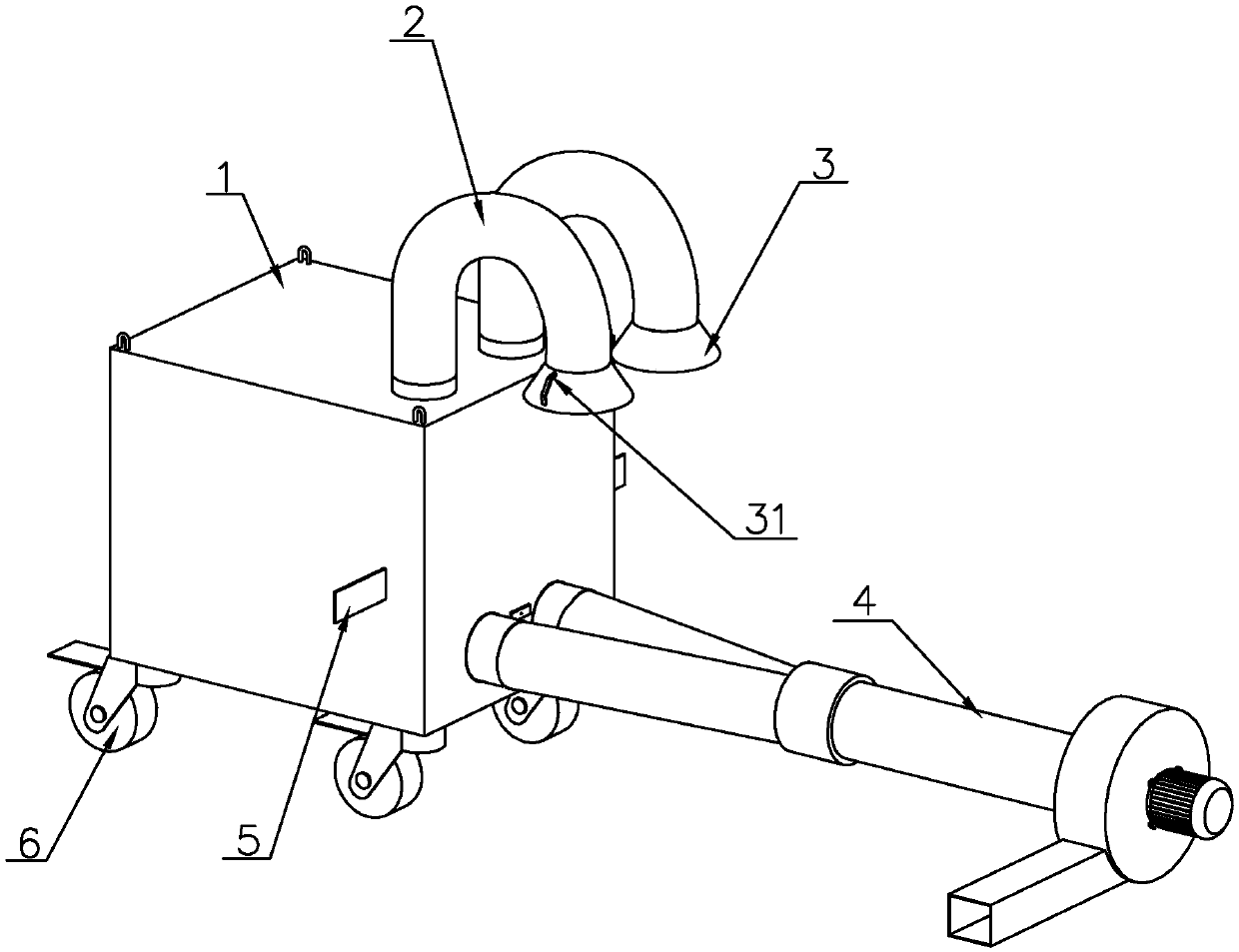

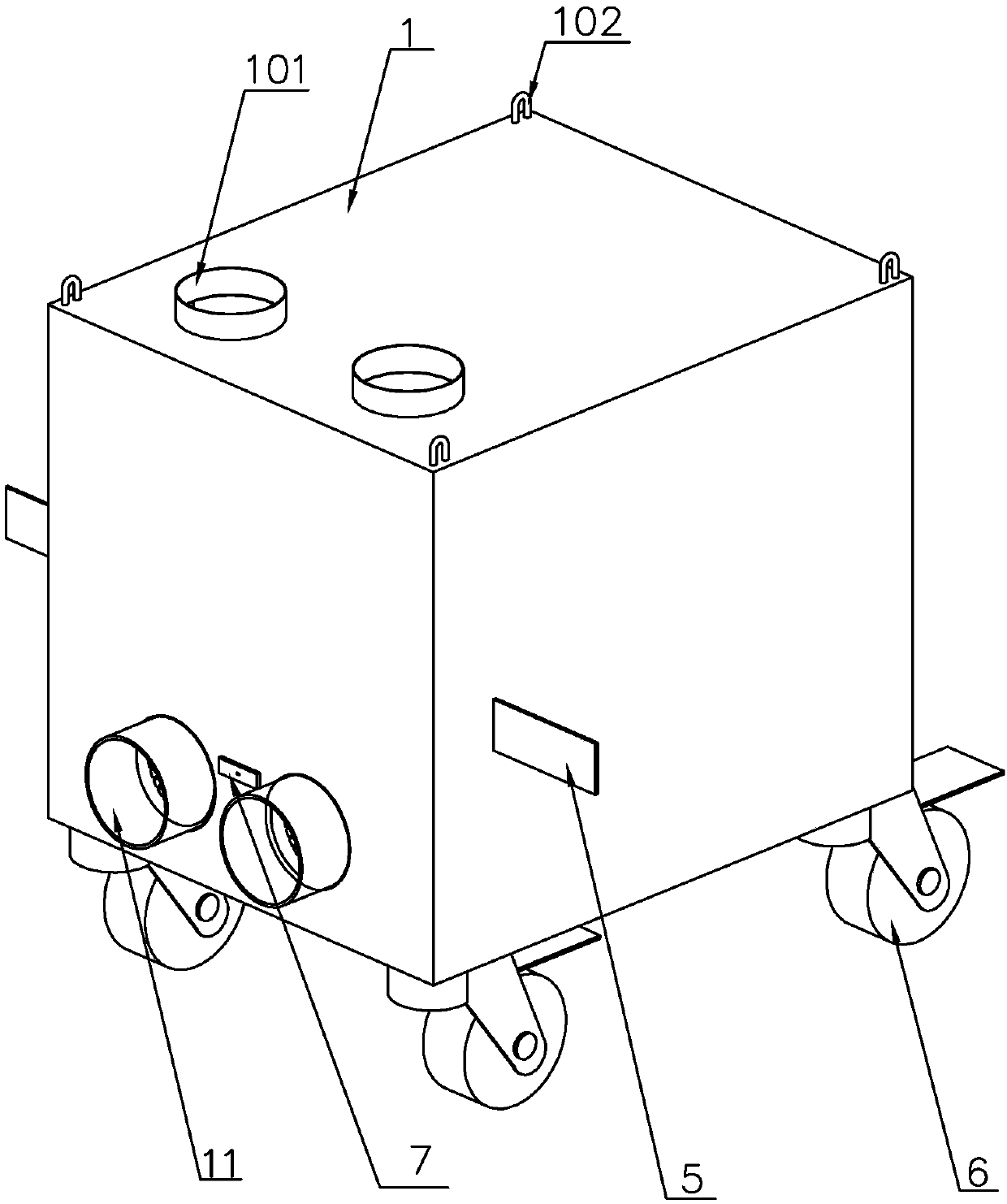

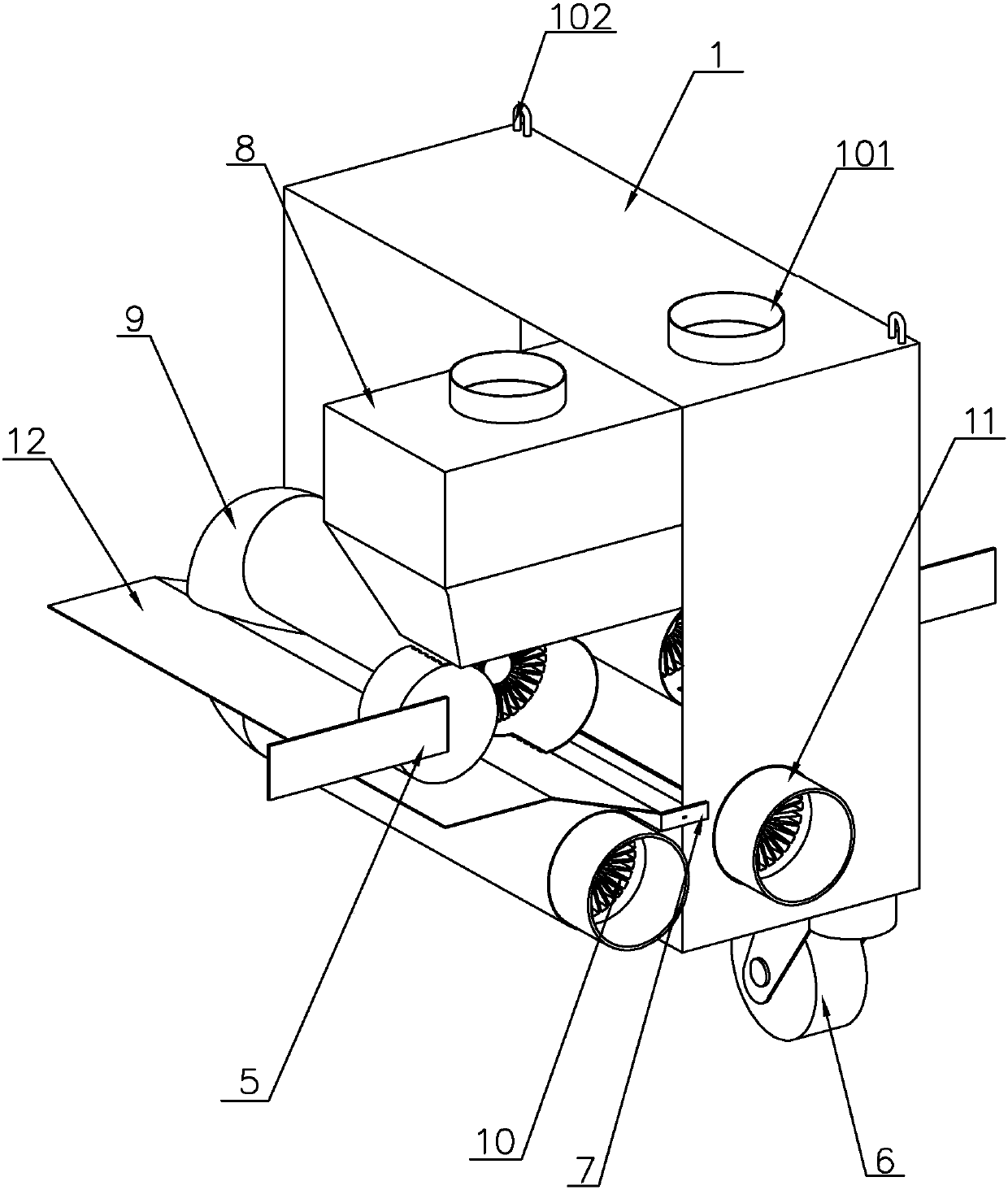

[0027] For the convenience of those skilled in the art to understand, the following in conjunction with the attached Figure 1-7 , to further specifically describe the technical solution of the present invention.

[0028] A welding fume purifier, including a box body 1, an inlet flange 101, a universal suction arm 2, a suction cover 3, an external device 4, a movable blocking cover 5, walking wheels 6, a dust accumulation drawer 7, and a gas collection chamber 8. Filtration pipeline 9, filter element 10, outlet flange 11, baffle plate 12; an inlet flange 101 is arranged above the box body 1, and the inlet flange 101 is installed in the box body 1, and a million To the suction arm 2, the head of the universal suction arm 2 is provided with a suction hood 3, the shape of the suction hood 3 is trumpet-shaped, which increases the area for absorbing welding fumes and improves work efficiency; the box body 1 There is a gas collection chamber 8 inside, the gas collection chamber 8 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com