Tagging system for production line integrated with labeling and collecting

A production line and coding technology, which is applied in the field of the coding system of the integrated production line of pasting and purchasing, can solve the problems of inability to scan and collect some products and difficult to achieve, and achieve the effects of simple structure, cost reduction and reasonable design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further explained below in conjunction with the accompanying drawings, but the protection scope of the present invention will not be limited.

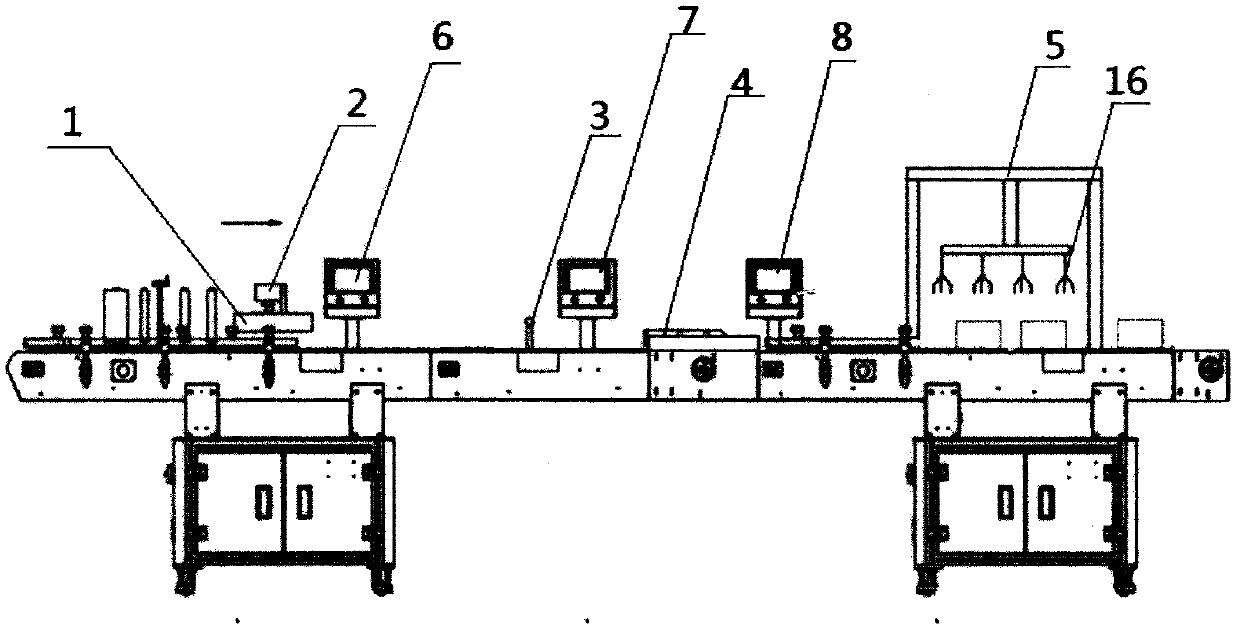

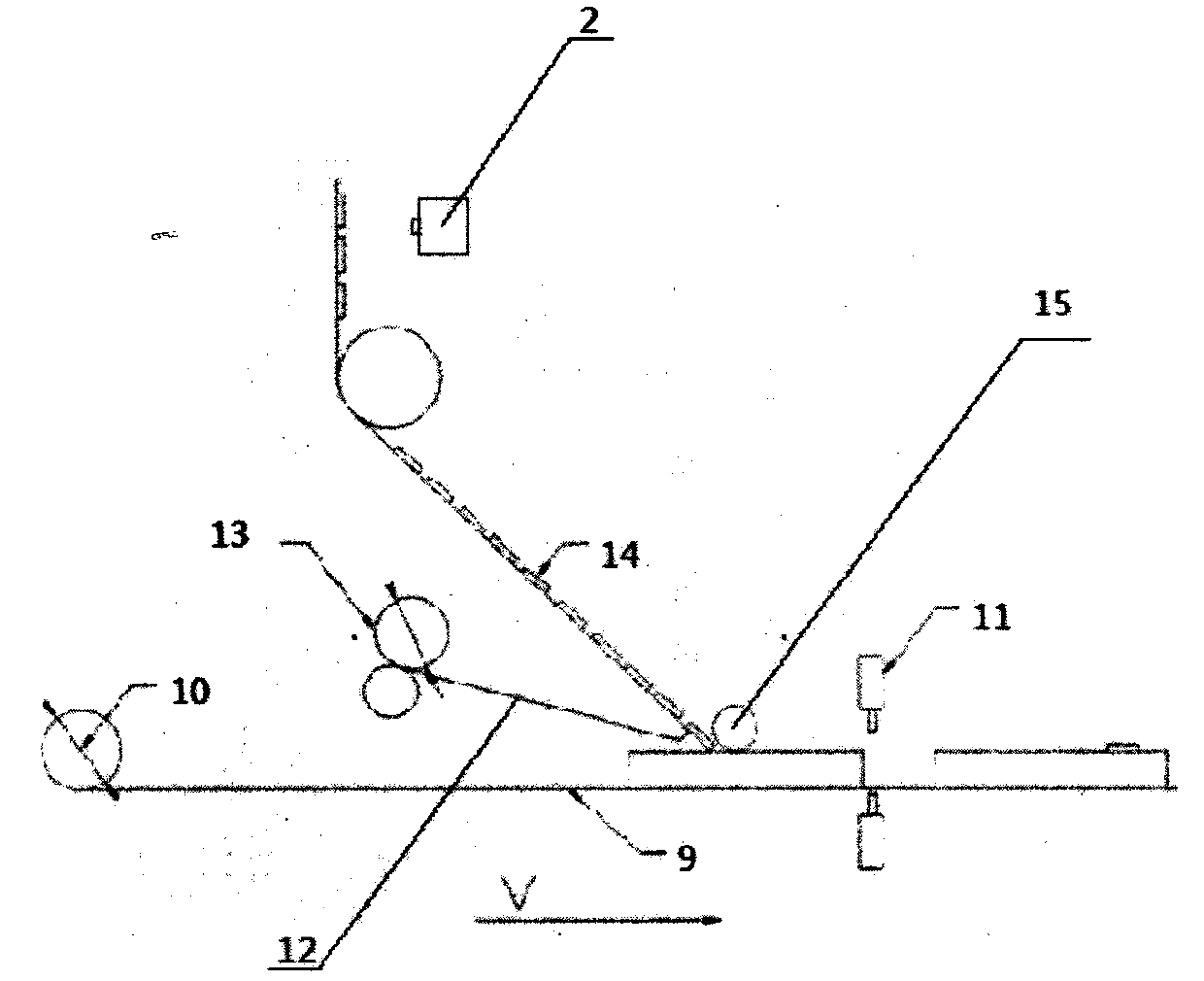

[0015] Such as Figure 1 to Figure 2 As shown, a labeling system for a production line integrating labeling and mining includes a labeling device 1 set according to the product flow direction, a collection host 2, a rejecting device 3, a shunting device 4 and an automatic boxing device 5. The collection host 2 and The labeling device 1 is connected in a short gap, the labeling device 1 and the collection host 2 are controlled by the first operation panel 6, the rejecting device 3 is controlled by the second operation panel 7, and the distribution device 4 is controlled by the third Controlled by the operation panel 8, the labeling device 1 includes a conveyor belt 9 that moves to the product flow direction. The conveyor belt 9 is respectively provided with an encoder 10 and a detection sensor 11 acc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com