Automatic oil filtering and air frying equipment for sweet potato chips

A technology of sweet potato chips and air frying, which is applied in the direction of filtration circuit, filtration separation, oil/fat baking, etc. It can solve the problems that sweet potato chips contain too much fat and cannot be processed, so as to increase the deliciousness and avoid harm to the human body , the effect of increasing the degree of health

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] The following description serves to disclose the present invention to enable those skilled in the art to carry out the present invention. The preferred embodiments described below are only examples, and those skilled in the art can devise other obvious variations.

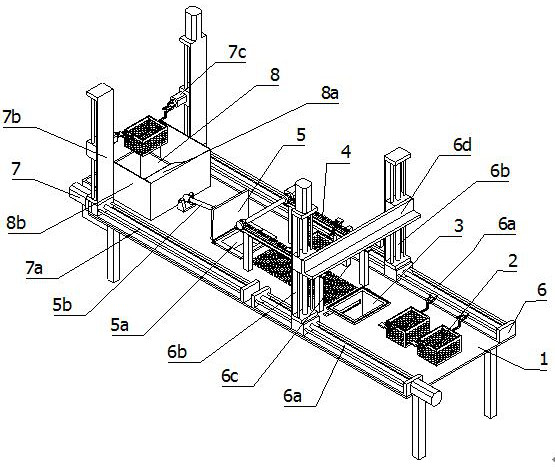

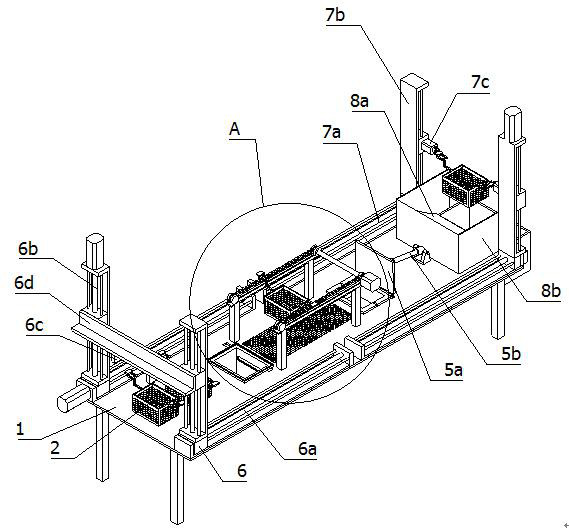

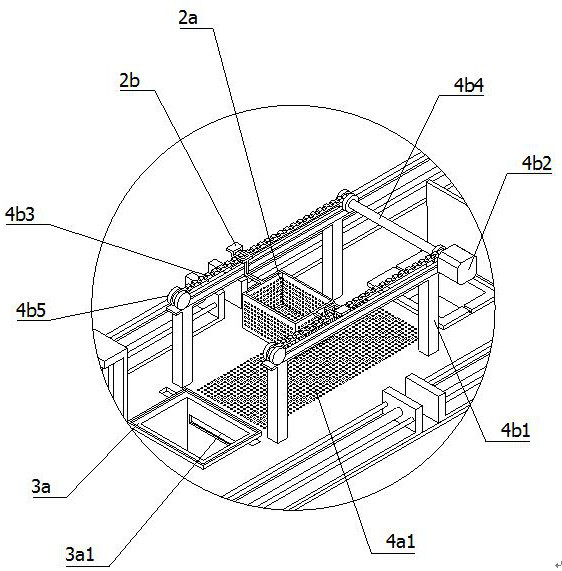

[0060] Such as figure 1 Shown is a device for automatically filtering oil and air frying sweet potato slices, including: workbench 1 and filter basket 2, on which workbench 1 is equipped with oil passing device 3, first industrial robot 6, oil draining device 4, second industrial Robot 7, air frying device 5, collecting box 8; oil passing device 3, oil draining device 4, air frying device 5, collecting box 8 are arranged in sequence, and oil passing device 3 and oil draining device 4 are all located in the first industrial robot 6 In the working area, the oil draining device 4, the air frying device 5 and the collecting device are all located in the working area of the second industrial robot 7; the both ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com