Sludge treatment equipment and sludge treatment method

A technology for treating equipment and sludge, which is applied in sludge treatment, water/sludge/sewage treatment, chemical instruments and methods, etc. It can solve the problem of easily damaged equipment and the inability to automatically adjust the proportion of acid sludge and alkaline sludge , uneven mixing of acid sludge and alkaline sludge, etc., to achieve the effect of uniform mixing and not easy to damage the equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

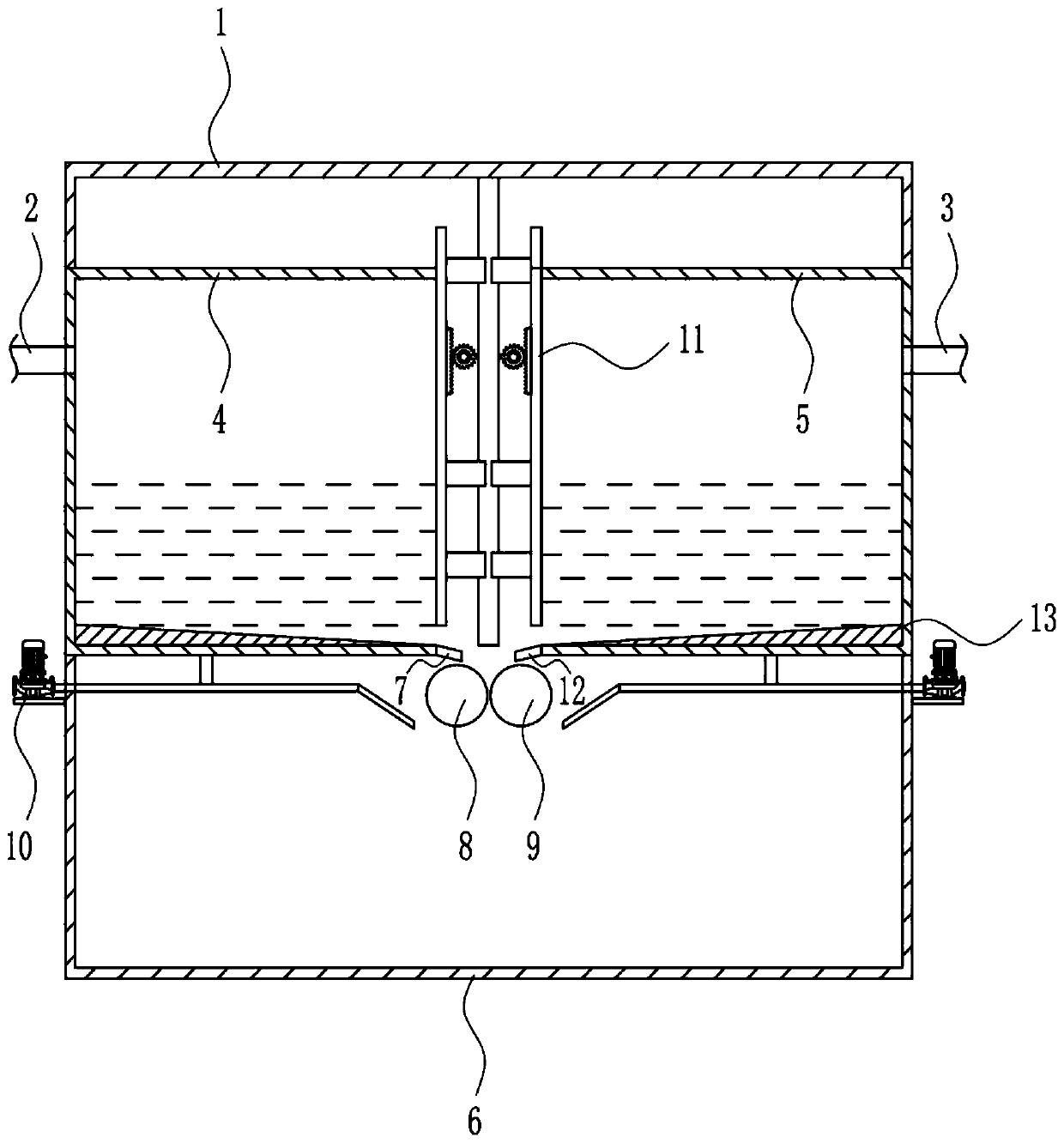

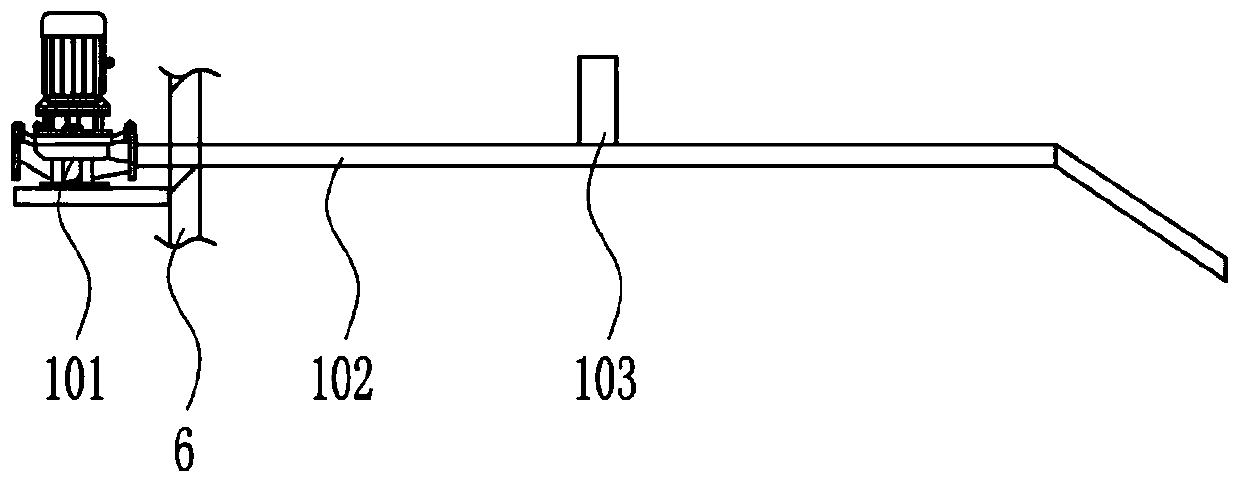

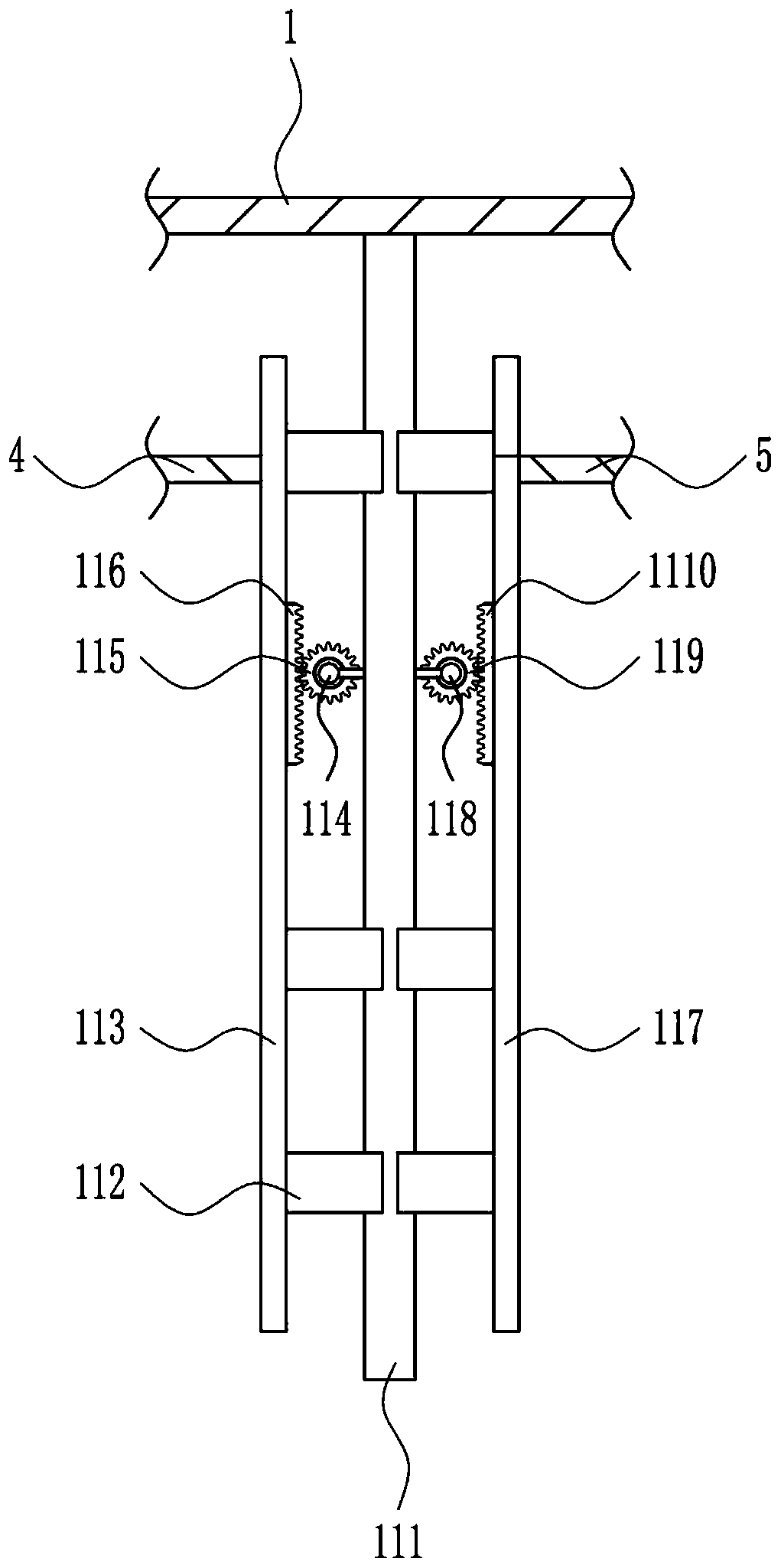

[0027] A sludge treatment equipment, such as Figure 1-3 As shown, it includes a frame 1, a first feed pipe 2, a second feed pipe 3, a first treatment box 4, a second treatment box 5, a collection box 6, a first guide plate 7, a first electric roller 8, The second electric roller 9, the high-pressure blowing mechanism 10, the height adjustment mechanism 11 and the second guide plate 12; 4 The first feed pipe 2 is installed on the upper part of the side away from the second treatment box 5, and the second feed pipe 3 is installed on the upper part of the second treatment box 5 away from the first treatment box 4; the bottom of the first treatment box 4 A side close to the second treatment box 5 is affixed with a first guide plate 7, and the bottom of the second treatment box 5 is affixed with a second guide plate 12 near the side of the first treatment box 4; The bottom of the treatment box 4 is affixed, and the top of the other side wall of the collection box 6 is affixed to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com