Method for stably synthesizing polycarboxylate superplasticizer under low temperature conditions

A technology for synthesizing polycarboxylic acid and low temperature conditions, applied in the field of concrete admixtures, can solve the problems of long synthesis time, decreased initiation efficiency, low utilization rate of polyether, etc., and achieves stable and excellent performance, high initiation efficiency and high conversion rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Under the condition of 5-20° C., 460 g of prenol polyoxyethylene ether with a molecular weight of 2400 and 360 g of water were added into a four-neck bottle reaction kettle and stirred to dissolve. Add 0.2g ferric oxide and ferrous oxide mixture (Fe 2 o 3 : FeO=1:3), then add 3g of ammonium persulfate. Mix 31g of acrylic acid and 57g of water to obtain liquid A. Mix 1.25g vitamin C and 2.2g mercaptopropionic acid with 65g water to obtain liquid B. Add liquid A and liquid B dropwise at the same time, liquid A is added dropwise for 150 minutes, and liquid B is added dropwise for 180 minutes. There is no need for heating or temperature control during the dropping process. After the dropwise addition, mature for 30 minutes, and then add 15 g of sodium hydroxide. Water is added to adjust the solid content, and the polycarboxylate superplasticizer with excellent slump retention performance can be obtained.

Embodiment 2

[0024] Under the condition of 5-20°C, add 420 g of methallyl alcohol polyoxyethylene ether with a molecular weight of 2400 and 380 g of water into a four-neck bottle reaction kettle and stir to dissolve. Add 0.2g ferric oxide to the reaction kettle, and then add 3.2g potassium persulfate. Mix 20g of acrylic acid and 55g of hydroxyethyl acrylate with 20g of water to obtain liquid A. Mix 0.6g of vitamin C and 1.9g of thioglycolic acid with 45g of water to obtain liquid B. Add liquid A and liquid B dropwise at the same time, liquid A is added dropwise for 120 minutes, and liquid B is added dropwise for 150 minutes. There is no need for heating or temperature control during the dropping process. After the dropwise addition, mature for 30 minutes, and then add 10 g of sodium hydroxide. Add water to adjust the solid content to obtain super slump polycarboxylate superplasticizer.

Embodiment 3

[0026] Under the condition of 5-25°C, add 400 g of ethylene glycol polyoxyethylene ether with a molecular weight of 3000 and 320 g of water into a four-neck bottle reaction kettle and stir to dissolve. Add 0.15g of rust to the reactor, and then add 4g of 30% hydrogen peroxide. Mix 35g of acrylic acid with 70g of water to obtain liquid A. Mix 1.0g vitamin C and 2.6g mercaptoethanol with 50g water to obtain liquid B. Add liquid A and liquid B dropwise at the same time, add liquid A dropwise for 60 minutes, add liquid B dropwise for 70 minutes, and control the temperature of the water bath not to exceed 30°C during the dropwise addition. After the dropwise addition, mature for 20 minutes, and then add 15 g of sodium hydroxide. Water is added to adjust the solid content, and a polycarboxylate superplasticizer with excellent comprehensive performance can be obtained.

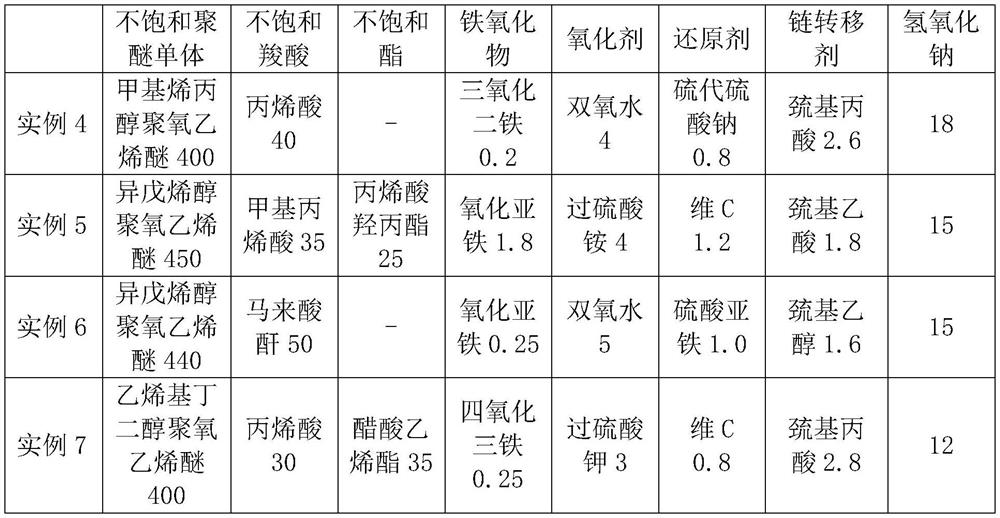

[0027] Examples 4-7 are shown in Table 1.

[0028] Table 1 Example raw material combination table (unit / g)

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com