Intelligent water energy cycle power saving system

A water energy and intelligent technology, applied in water supply pipeline system, hydroelectric power generation, industrial water supply saving, etc., can solve the problems of reduced energy consumption of circulating water, unsatisfactory power saving effect, surplus actual flow, etc., to reduce power consumption, reduce The effect of manual management cost and reducing manual misoperation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

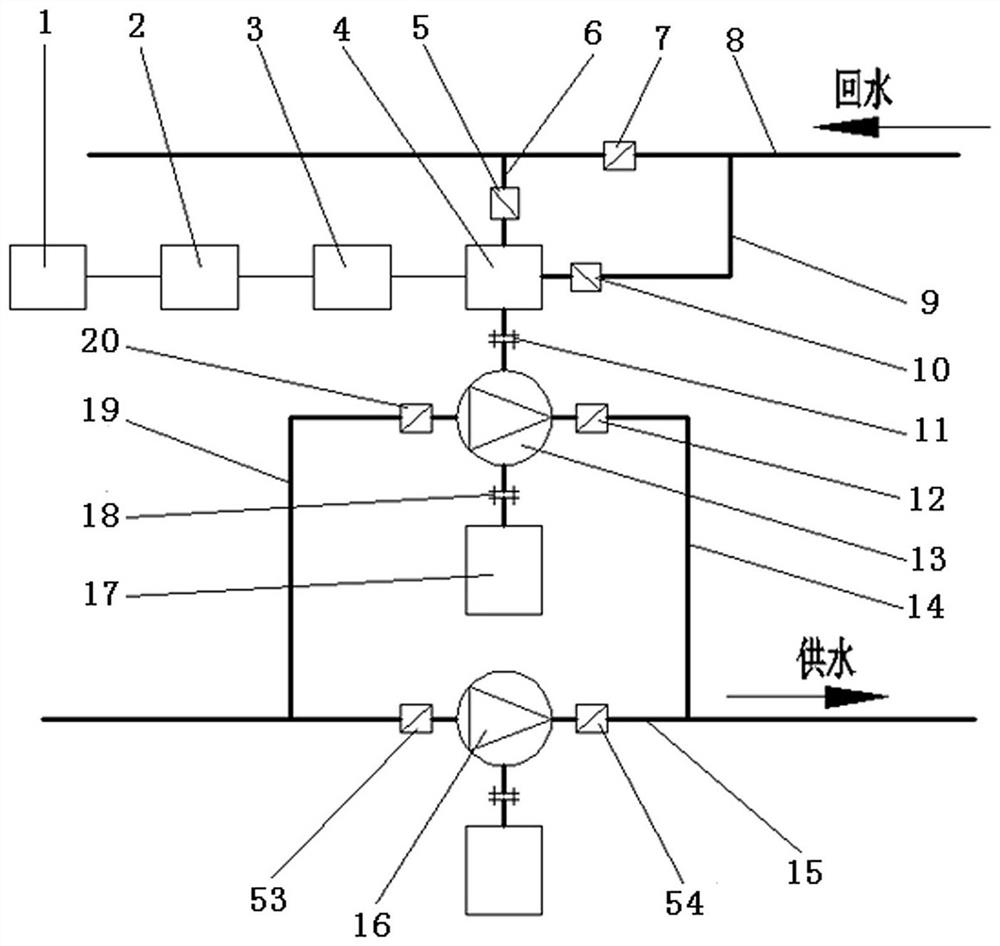

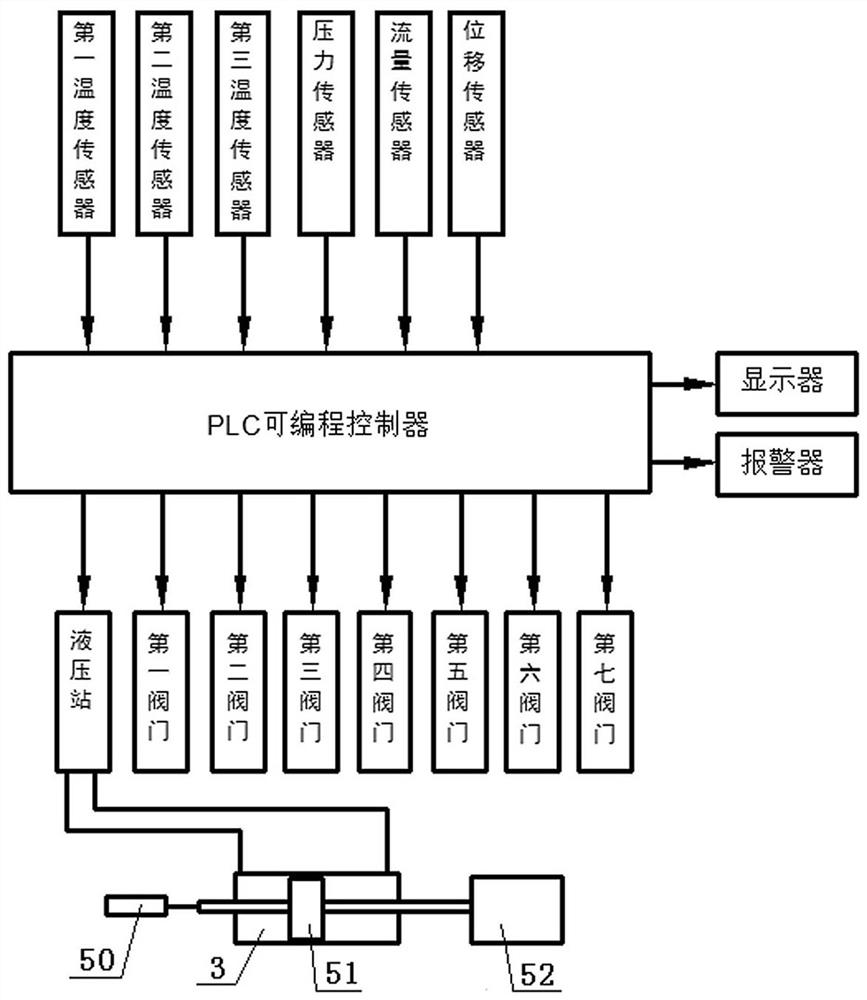

[0023] figure 1 It is to add a set of intelligent water energy circulation and power saving system to the usual water pump circulation water supply system. The intelligent water energy cycle power-saving system consists of an intelligent control device, a hydraulic turbine bypass, and a high-efficiency water pump bypass. The turbine bypass is composed of a Francis turbine 4 , a first water inlet pipeline 9 , a first valve 10 , a first water outlet pipeline 6 and a second valve 5 . The intelligent control device is composed of several sensors, an intelligent control cabinet 1, a hydraulic station 2 and a servomotor 3. The high-efficiency water pump bypass is composed of a high-efficiency water pump 13, a second water inlet pipeline 19, a third valve 20, a second water outlet pipeline 14, a fourth valve 12, and an asynchronous motor 17.

[0024] One end shaft of the high-efficiency water pump 13 is connected to the shaft of the water turbine 4 through the first coupling 11, an...

Embodiment 2

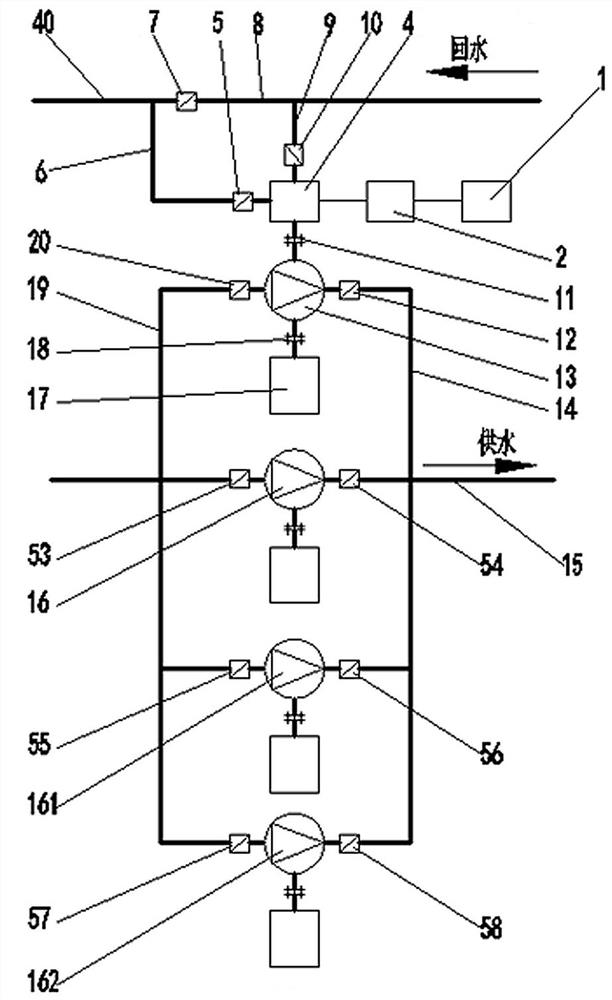

[0035] Add a set of intelligent water energy cycle power saving system to the usual multi-pump circulating water supply system, such as image 3 It is a common water supply system with dual-use and one-standby or one-use and two-standby. The intelligent water energy cycle power-saving system consists of an intelligent control device, a hydraulic turbine bypass, and a high-efficiency water pump bypass. The hydraulic turbine bypass is composed of a hydraulic turbine 4 , a first water inlet pipeline 9 , a first valve 10 , a first water outlet pipeline 6 and a second valve 5 . In the water supply system with low return water pressure, the water turbine 4 is suitable to adopt the rear shaft extension through-flow paddle type water turbine. The intelligent control device is composed of several sensors, an intelligent control cabinet 1 and a hydraulic station 2. The high-efficiency water pump bypass is composed of a high-efficiency water pump 13, a second water inlet pipeline 19, a...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap