Speed bump power generation device and working method

A technology for power generation devices and speed bumps, applied in electromechanical devices, electric components, electrical components, etc., can solve problems such as loss of kinetic energy and energy waste in automobiles, and achieve the effects of avoiding waste, being easy to manufacture, and improving comfort.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0044] This embodiment discloses a working method of a deceleration belt power generation device:

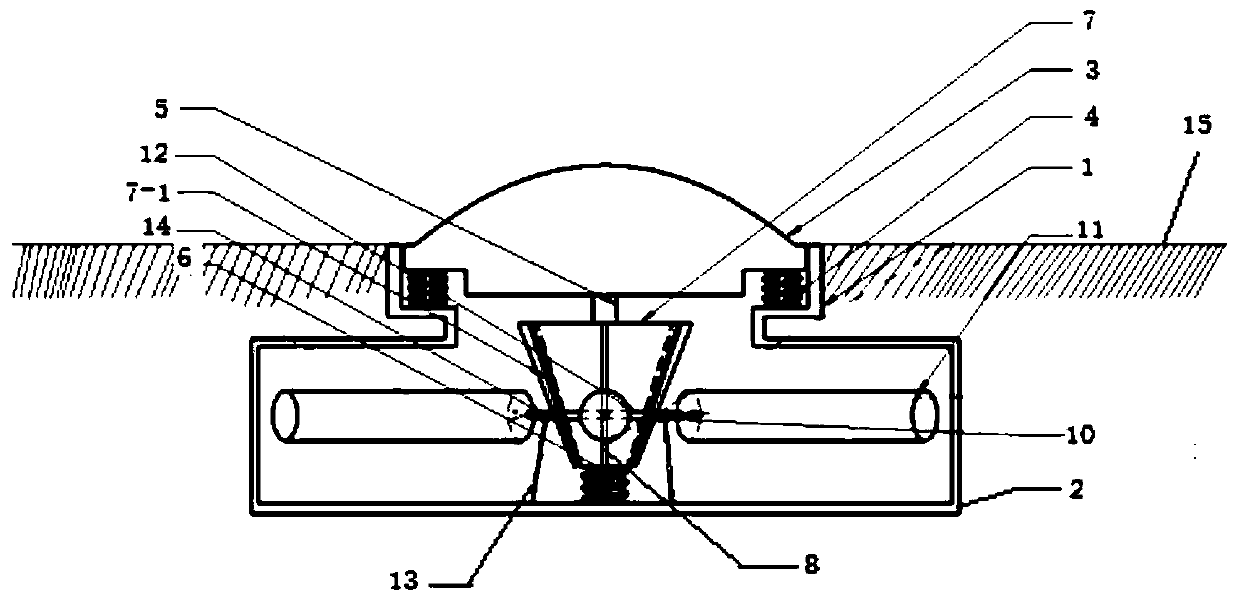

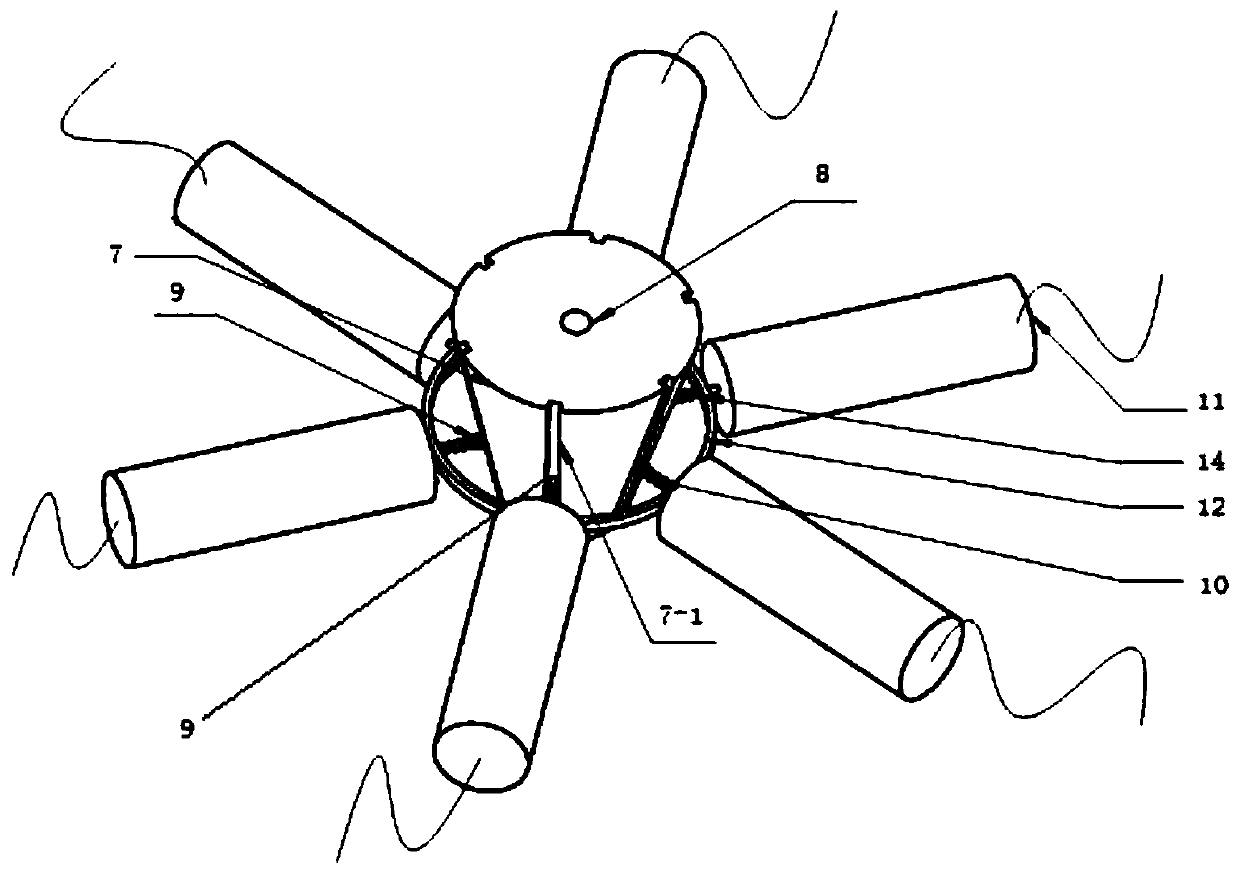

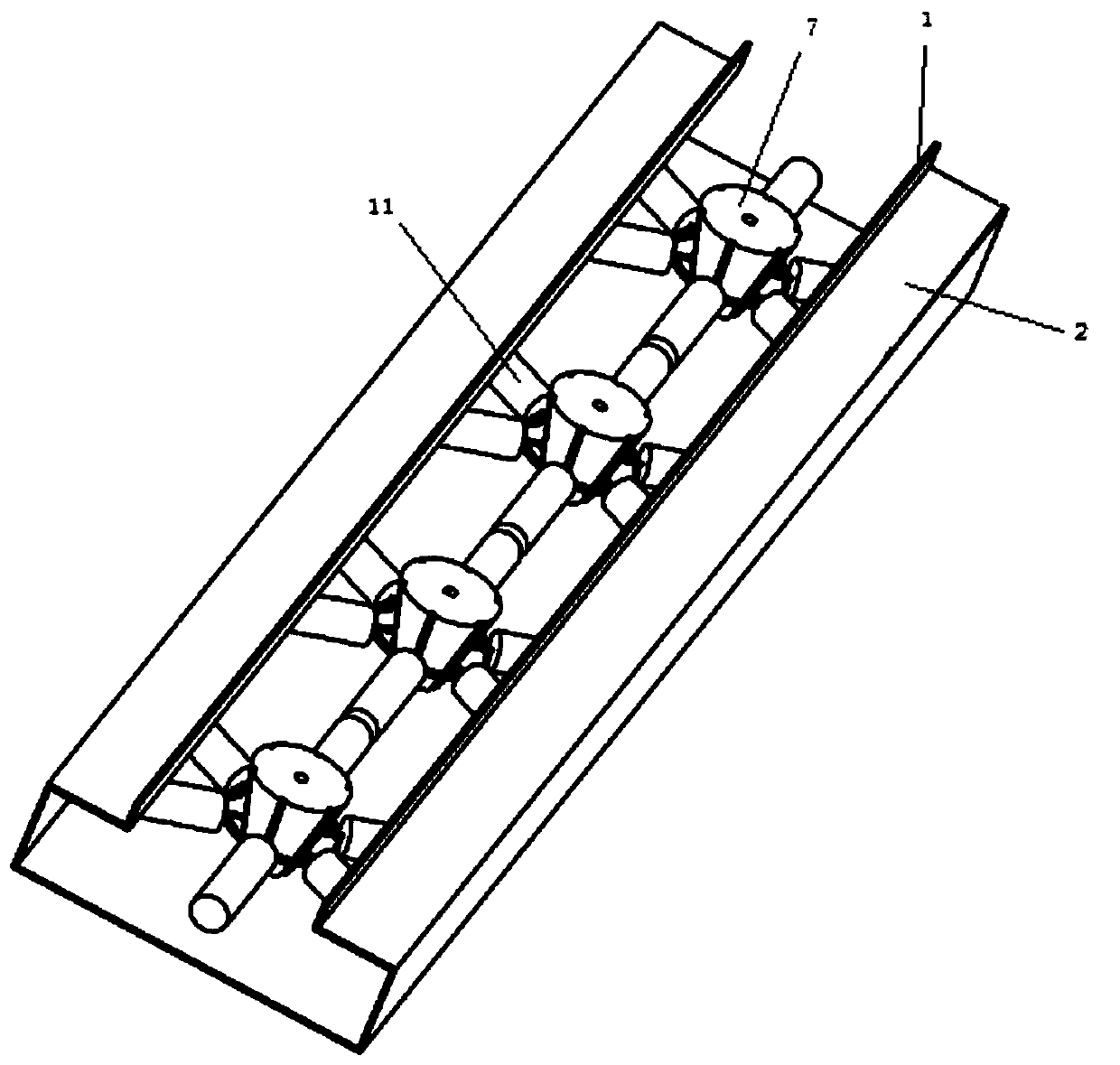

[0045] The casing is buried 15 below the ground, and the top surface of the casing is flush with the ground. When the vehicle is running against the speed bump, the speed bump moves downward under the action of the vehicle pressure, and the inverted conical frustum moves downward synchronously. Contacting the side of the inverted cone, the downward movement of the inverted cone drives the transmission rod to move away from the axis of the inverted cone, and the movement of the transmission rod drives the linear generator to generate electricity. When the wheels of the vehicle leave the speed reduction belt, the first spring and Under the action of the second spring, the deceleration belt and the transmission part move upwards and return to their original positions. At the same time, under the action of the third spring, the transmission rod moves toward the axis of the inverted c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com