Raw material and ingredient transportation device

A technology for transportation devices and raw and auxiliary materials, which is applied in furnaces, lighting and heating equipment, furnace components, etc., can solve problems such as affecting the composition of molten metal, difficult to achieve precision casting and melting, affecting melting efficiency and melting cost, etc. The effect of melting efficiency and precision, cost reduction, and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

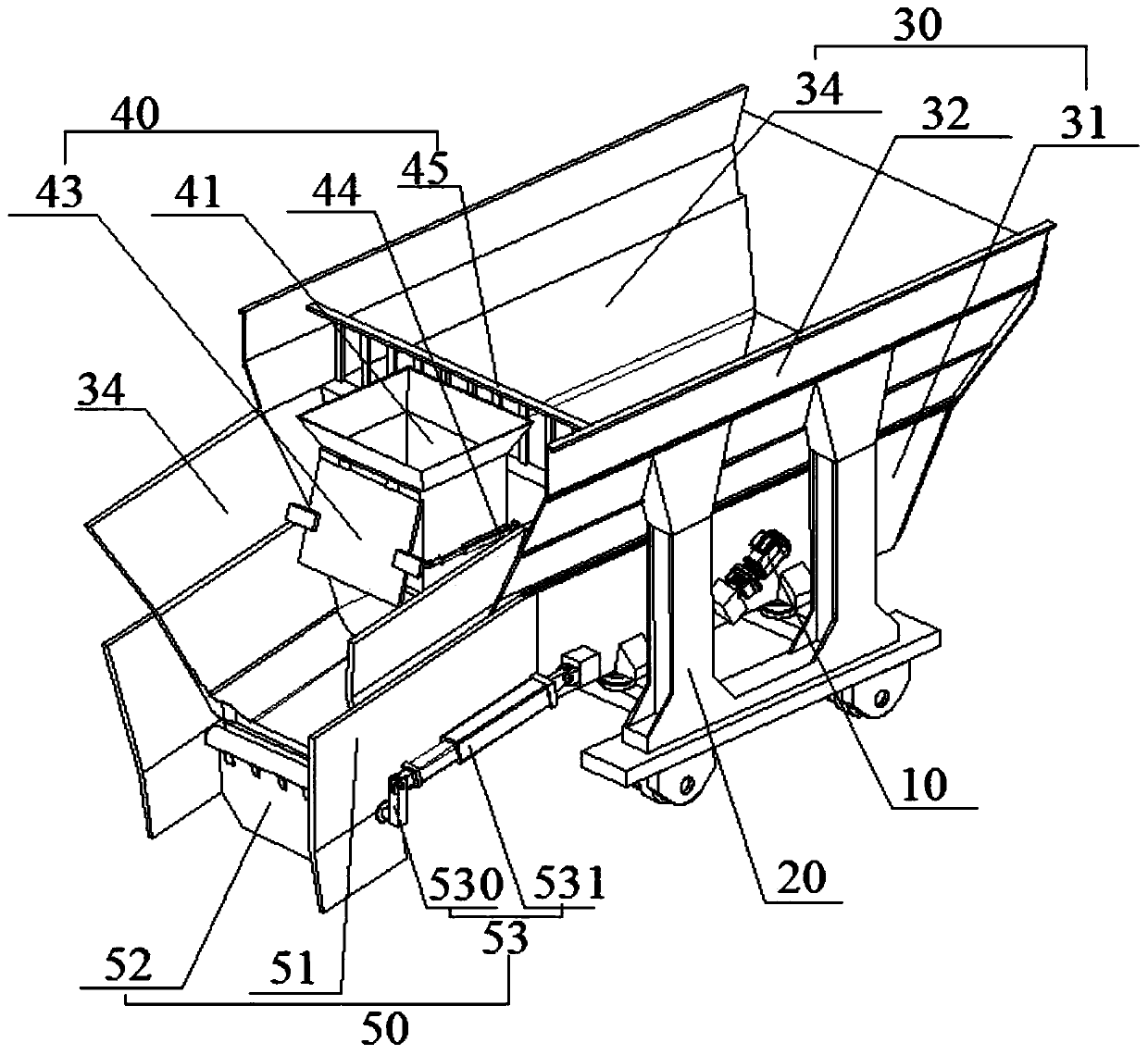

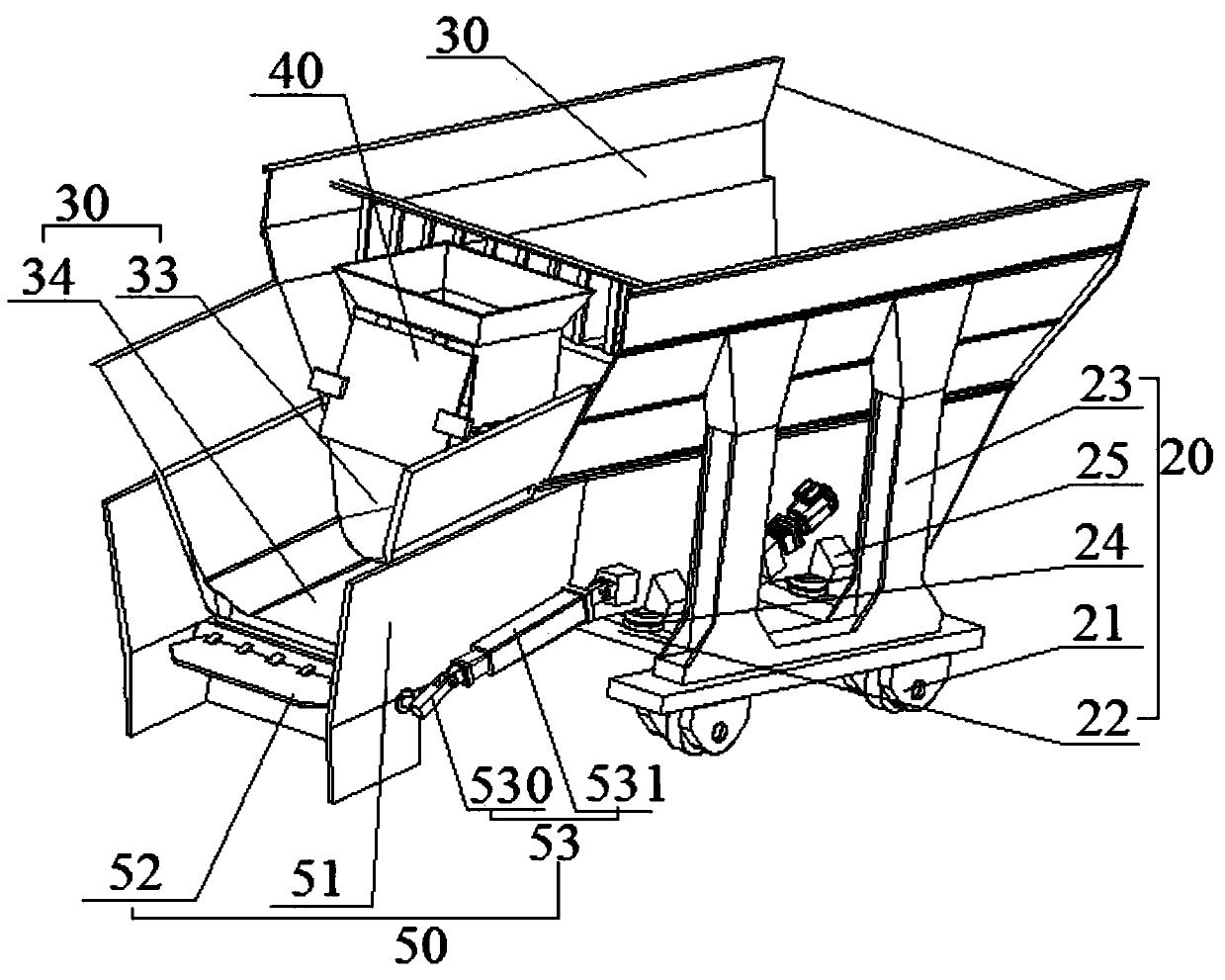

[0023] A technical solution of the embodiment of the invention will be further elaborated in detail with reference to the accompanying drawings of the invention.

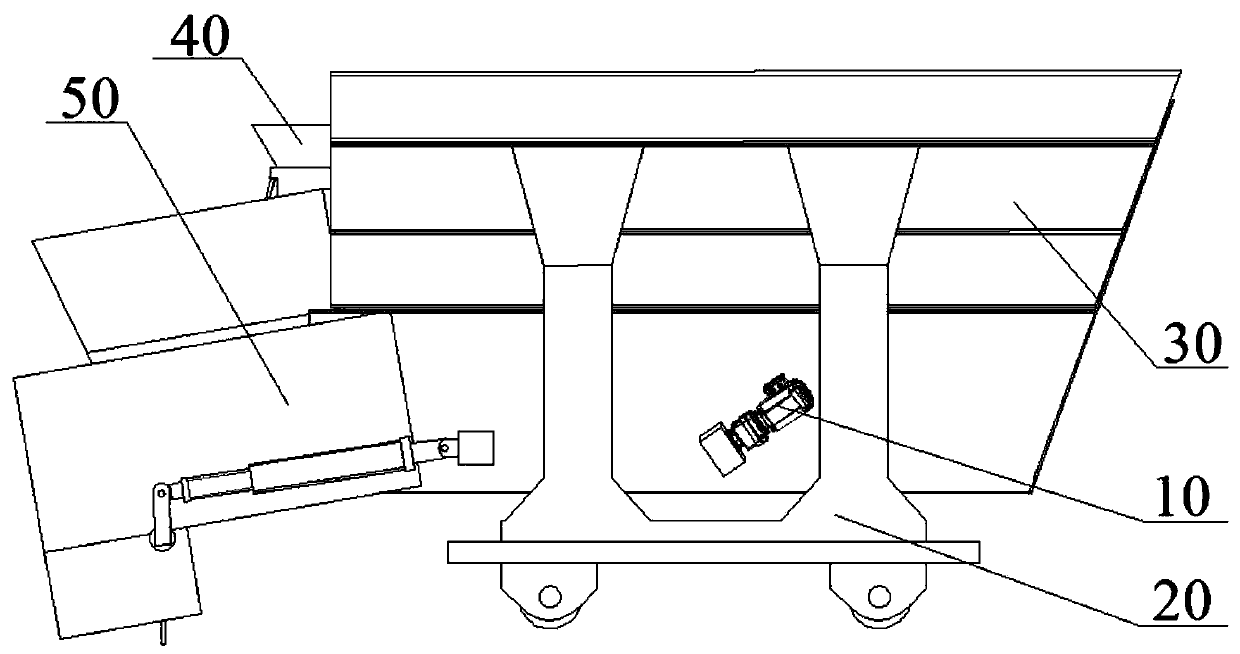

[0024] Refer to attached figure 1 As shown, a raw and auxiliary material transportation device includes a vibrating device 10, a sliding device 20, and a raw material bin 30, an auxiliary material bin 40, and a discharge passage 50 arranged on the upper part of the sliding device 20. The discharge passage 50 communicates with the raw material bin 30, and At the same time, the unloading passage 50 communicates with the auxiliary material bin 40. The unloading passage 50 has a discharge opening, and the unloading passage 50 is inclined toward the discharge opening.

[0025] Separately set raw material bin 30 and auxiliary material bin 40 are designed and controlled according to different raw and auxiliary materials, and both enter the discharge channel 50, and discharge from one discharge port. The inclined setting of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com