Structure residual bearing capacity measuring method and system based on tunnel lining deformation features

A tunnel structure and measurement system technology, applied in the direction of applying stable tension/pressure to test material strength, measuring devices, strength characteristics, etc., can solve problems such as irrationality, lack of tunnel safety state diagnosis methods, and error handling, etc. combined with high accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments. This embodiment is carried out on the premise of the technical solution of the present invention, and detailed implementation and specific operation process are given, but the protection scope of the present invention is not limited to the following embodiments.

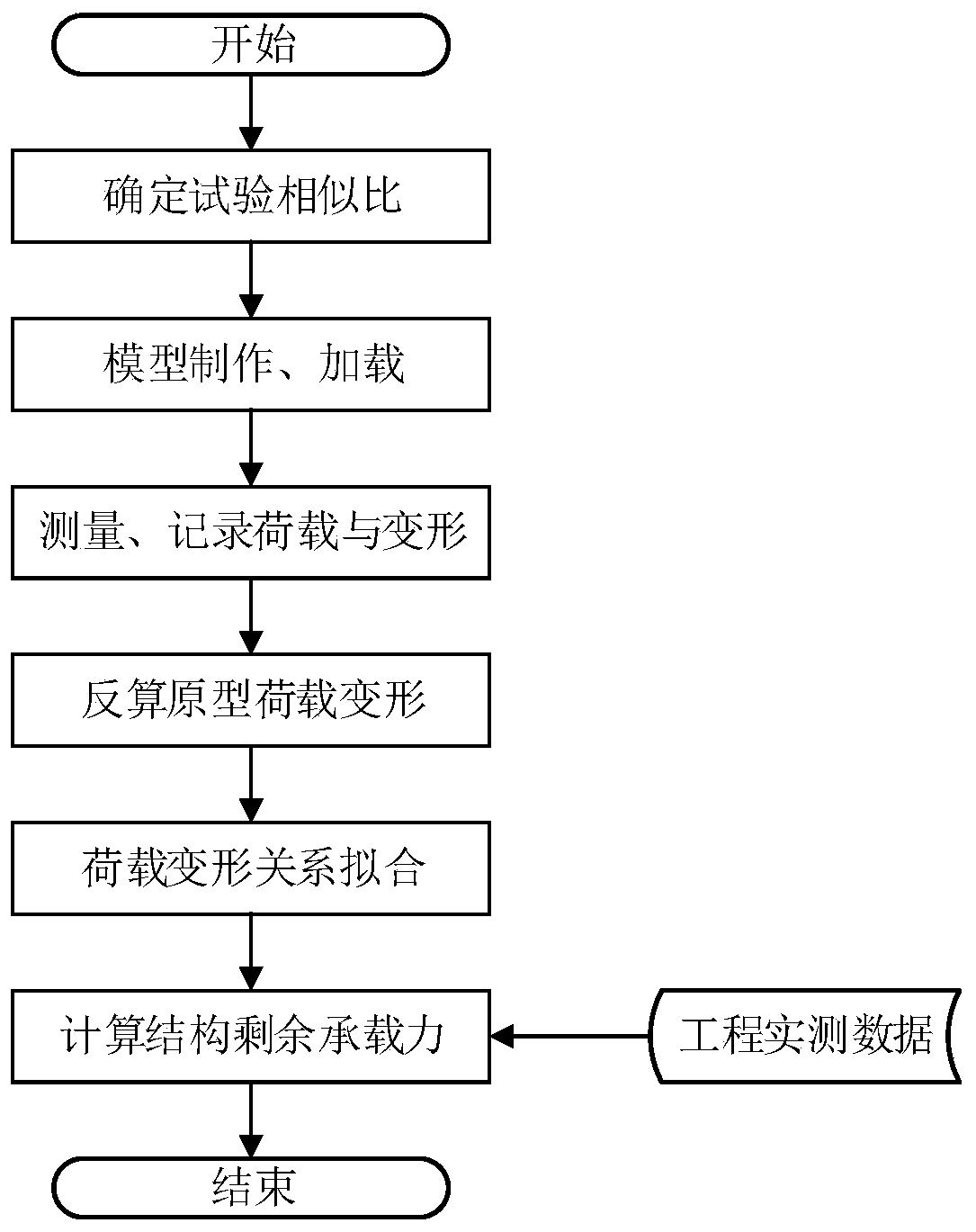

[0044] This embodiment provides a method for determining the residual bearing capacity of a structure based on the deformation characteristics of the tunnel lining, which is applicable to various highway tunnel sections built in IV-VI surrounding rock sections, including the following steps:

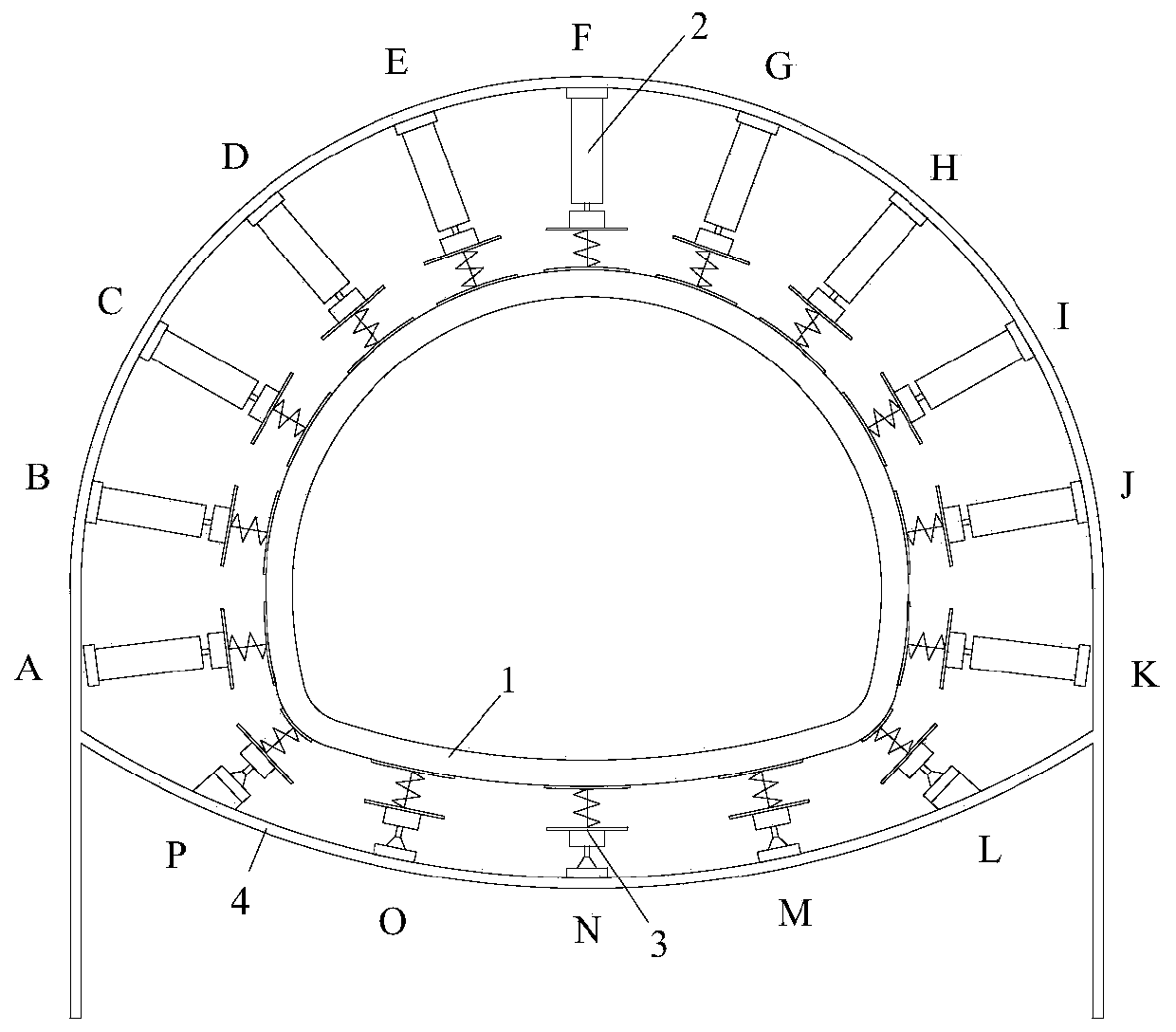

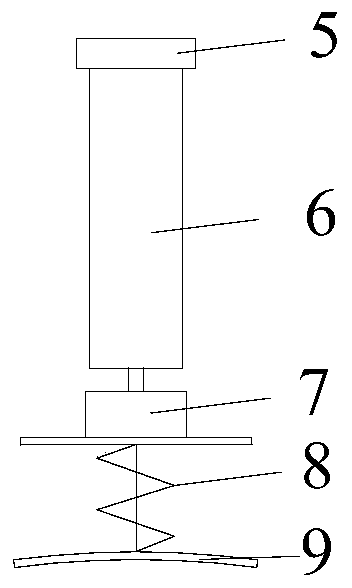

[0045] 1) According to the actual tunnel structure, the lining model is made by setting the similarity ratio, which includes geometry, strength, elastic modulus, strain, displacement, surface force, physical force, force, bending moment, formation resistance coefficient and reinforcement ratio s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com