Magnetic modulation current sensor and fabrication method thereof

A current sensor and magnetic modulation technology, applied in the direction of only measuring current, manufacturing measuring instruments, measuring current/voltage, etc., can solve the problem of asymmetric magnetic field of excitation magnetic core, improve filtering effect, suppress modulation noise, increase and so on The effect of the effective filter inductance value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below in conjunction with the drawings, preferred embodiments of the present invention are given and described in detail.

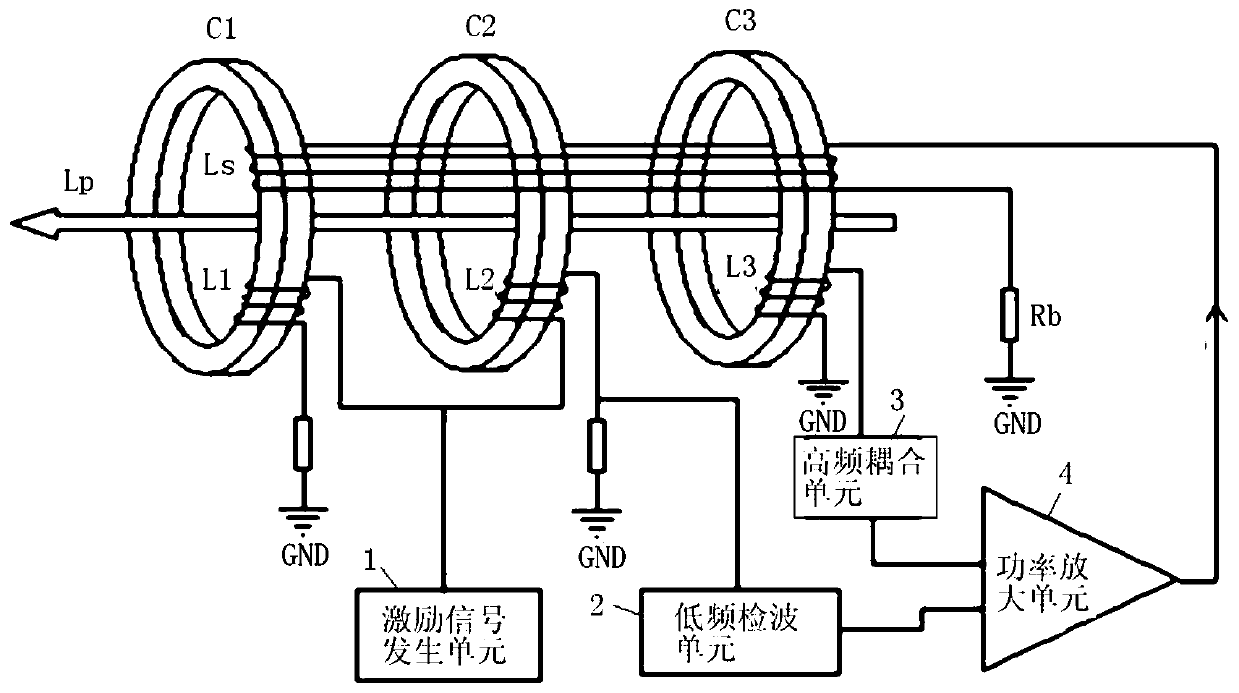

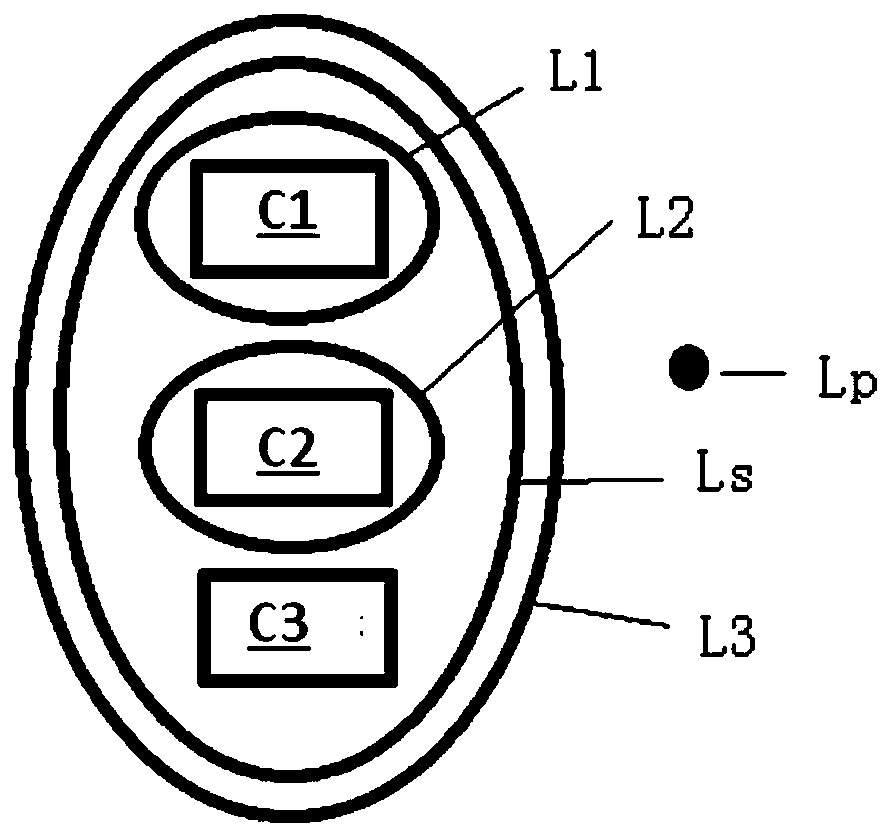

[0024] like figure 1 Shown is a schematic diagram of a magnetically modulated current sensor according to one embodiment of the invention. The magnetic modulation current sensor can significantly reduce the modulation noise of the magnetic modulation current sensor without affecting the AC characteristics, and it includes: the first magnetic core C1 and the second magnetic core C2 stacked together to form an integral magnetic core with the same axis and the third magnetic core C3, wherein the first magnetic core C1, the second magnetic core C2 and the third magnetic core C3 are respectively wound with the first coil L1, the second coil L2 and the auxiliary coil L3, and the overall magnetic core is wound A primary coil Lp and a secondary coil Ls are made. The primary coil Lp receives the measured DC current or the measured AC current input from the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com