Microscope observation head which is convenient for installation and positioning

A technology for installation and positioning of microscopes, which is applied in the field of microscopes, can solve problems such as unsuitability, troublesome disassembly, ugly clear images, etc., and achieve the effect of convenient disassembly and convenient positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

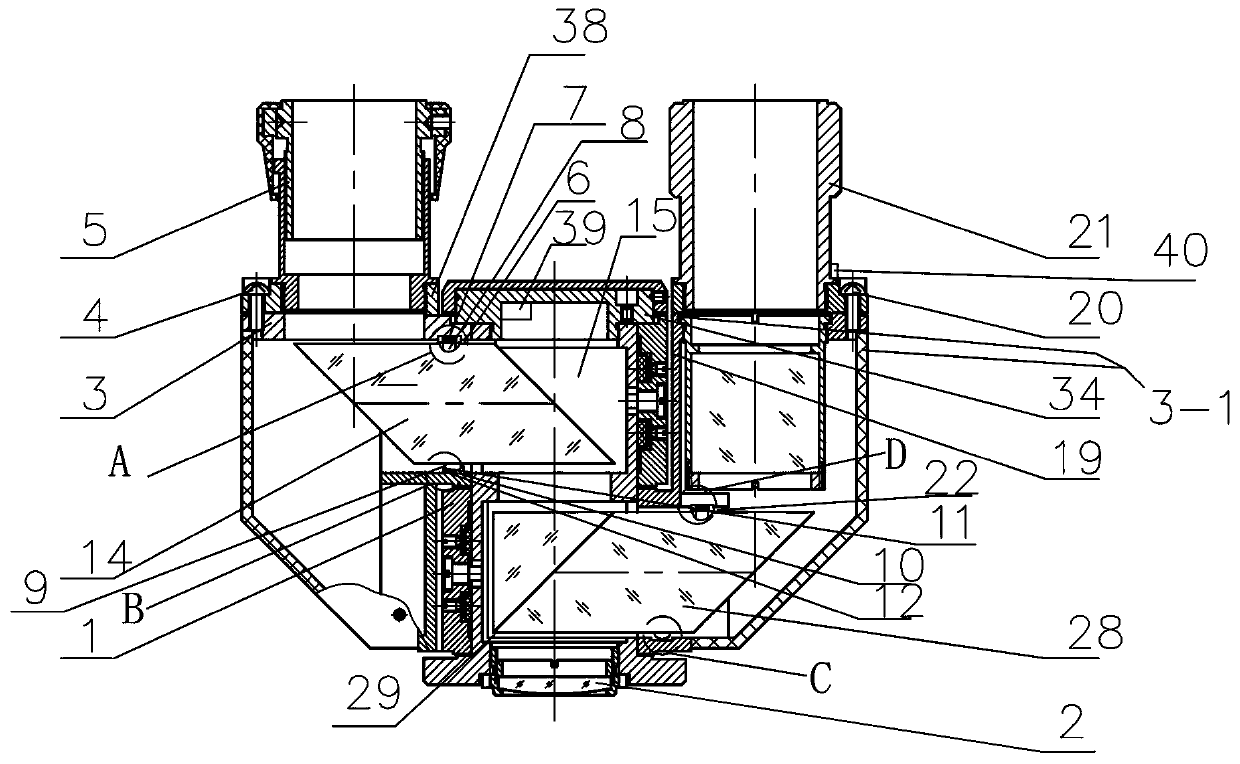

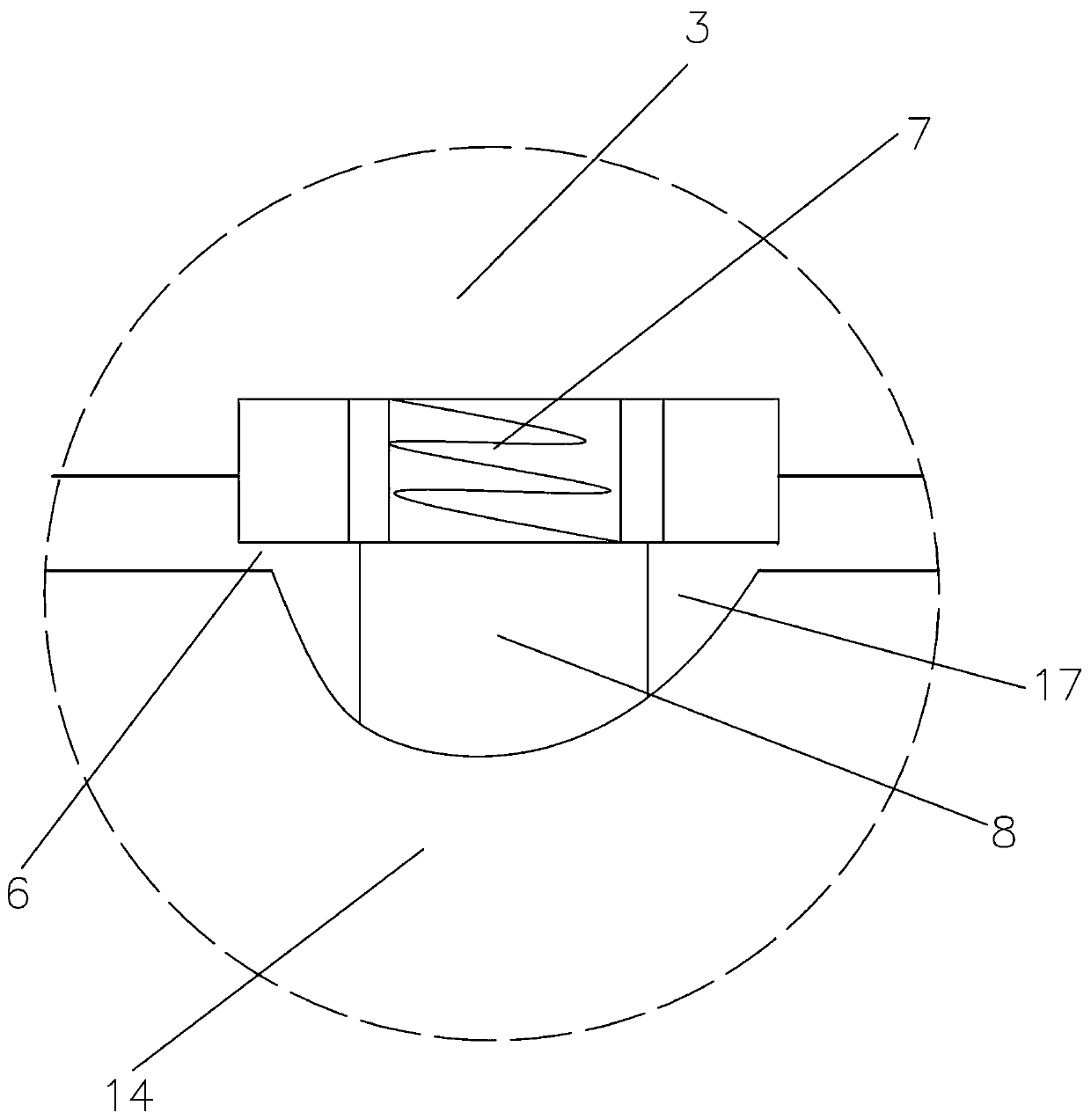

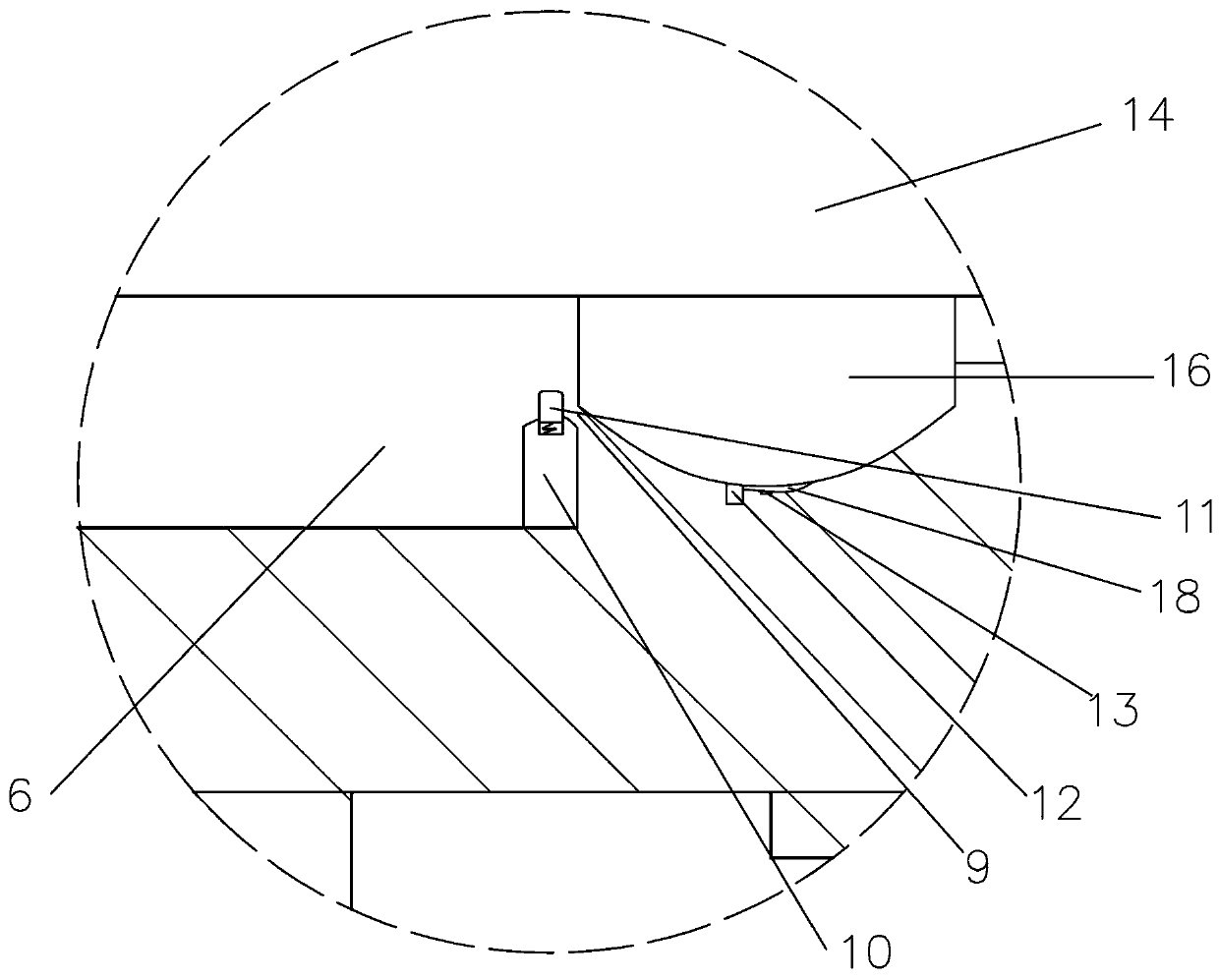

[0022] Such as Figure 1-Figure 8 As shown, a microscope observation head that is convenient for installation and positioning provided in this embodiment includes a rotating shaft 1, and a lens 2 is arranged under the rotating shaft 1, and lens 2 is arranged symmetrically on the left and right sides of the rotating shaft 1, which can be adjusted by rotating around the rotating shaft 1. The left viewing assembly and the right viewing assembly of the size of the interpupillary distance, the left viewing assembly includes a left prism support 3 that can rotate around the axis line of the rotating shaft 1, and a screw 4 that can turn inward is fixed above the left prism support 3. The left eyepiece tube 5 for observation is provided with a first notch 6 on one side of the left prism support 3, a first spring 7 is fixed on the upper wall of the first notch 6, and a first limit post is fixed below the first spring 7 8. A first groove 9 is provided below the first notch 6, a first li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com