Pin insertion method based on connector pin device

A technology for pin insertion equipment and connectors, applied in the field of auto parts, can solve the problems affecting the progress of the assembly process, low production capacity, low pin production efficiency, etc., and achieve the effect of improving pin insertion efficiency and high production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

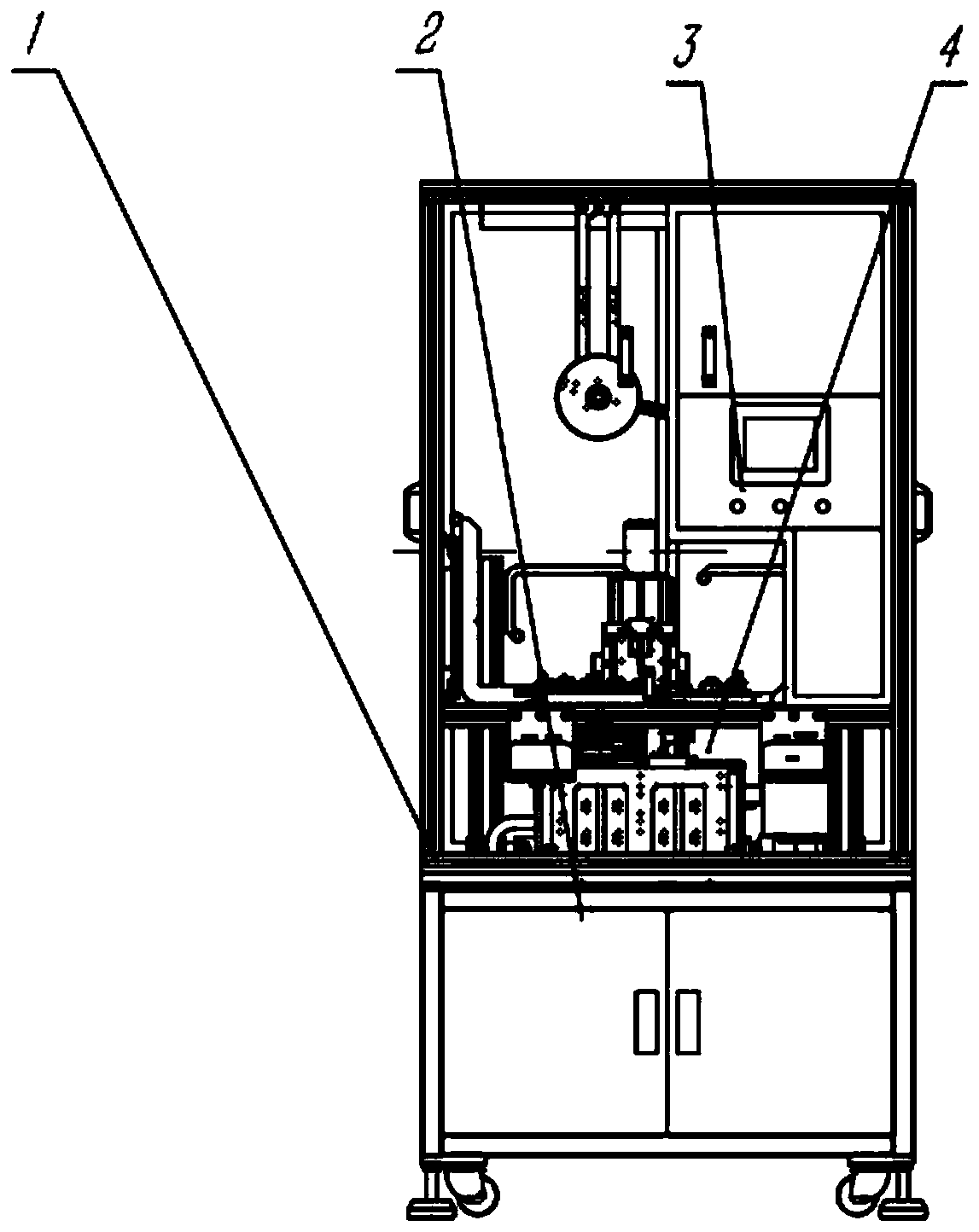

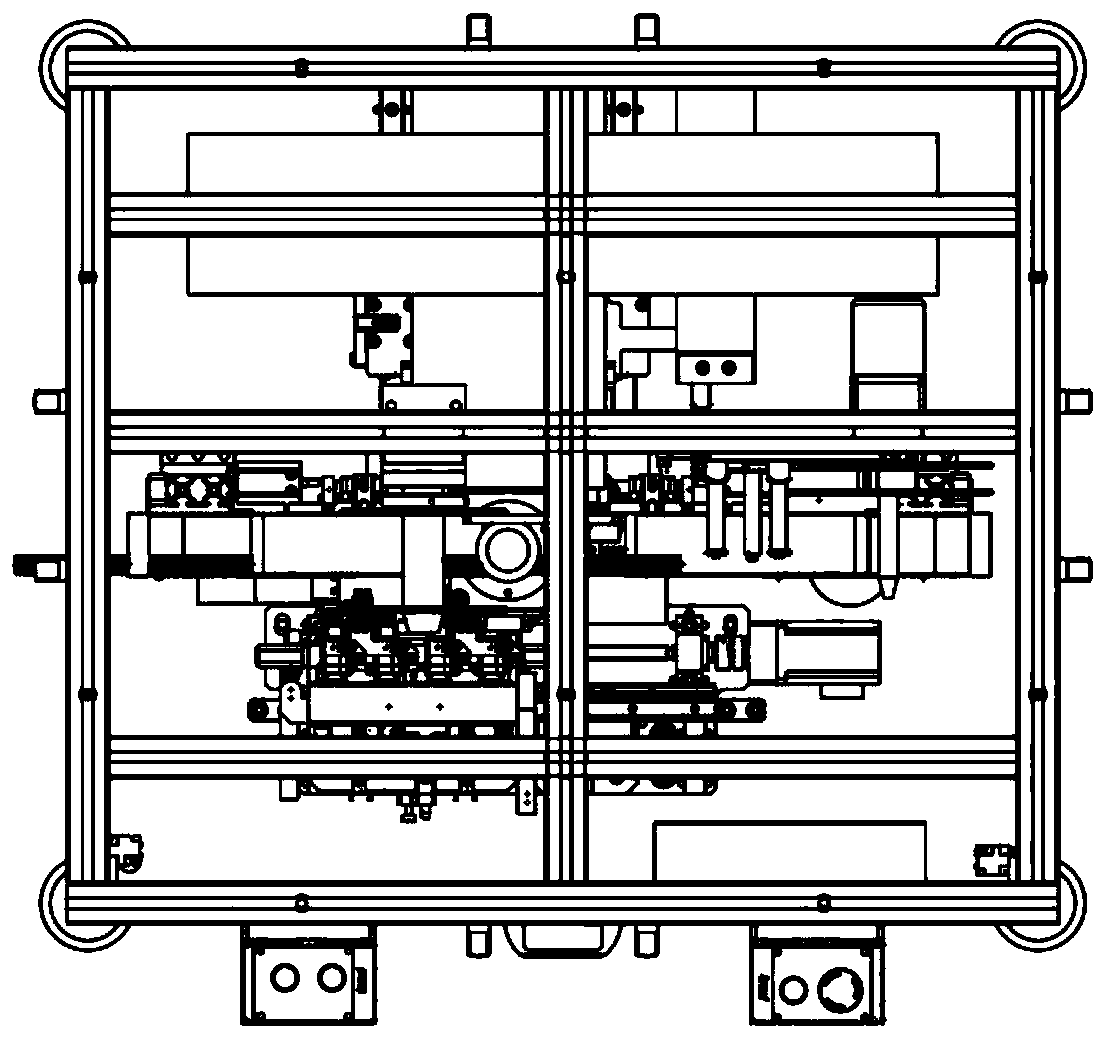

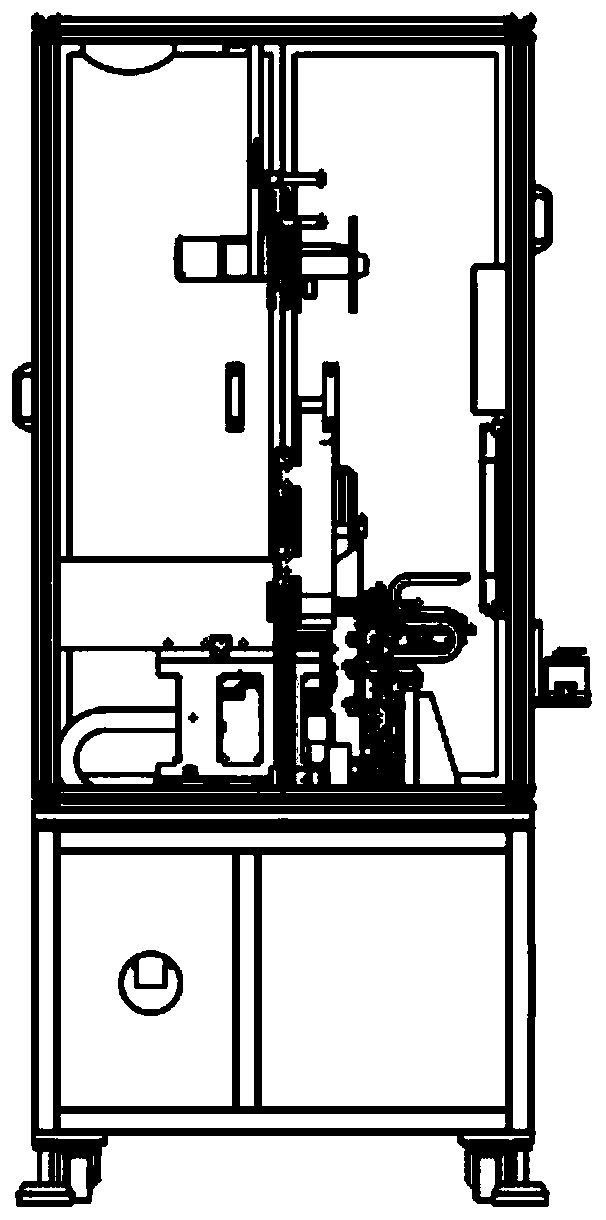

[0088] Such as Figure 1-Figure 6 As shown, a connector pin device, including:

[0089] Rack 1, the bottom of the rack 1 includes an electrical cabinet 2, the skeleton structure of the rack 1 is made of aluminum profiles, and each door is a sheet metal bending part; it is welded by square tubes, and the stress is relieved after welding After annealing treatment, frame 1 has good stability. The rest of the panels are bent by Q235 material sheet metal parts. Q235 has good ductility, good bending performance, and can well guarantee its size and beautiful appearance. The electrical components in the equipment are all installed inside the electrical cabinet 2, which is convenient for maintenance and wiring.

[0090] The characteristic mechanism 4 is arranged on the platform of the electrical cabinet 2, and the characteristic mechanism 4 includes a connector feeding mechanism 5, a symmetrically arranged pin feeding mechanism 6 and a pin mechanism 7; and a control panel 3 located o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com