A sample surface treatment auxiliary equipment

A kind of auxiliary equipment and surface treatment technology, which is applied in the direction of metal processing equipment, grinding/polishing equipment, grinding workpiece support, etc., can solve the problems of difficult application, complicated operation, and inability to effectively control the amount of sample grinding, and meet the requirements of Convenience, improved dimensional accuracy, and the effect of meeting low cost and quickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to better explain the present invention and facilitate understanding, the present invention will be described in detail below through specific embodiments in conjunction with the accompanying drawings.

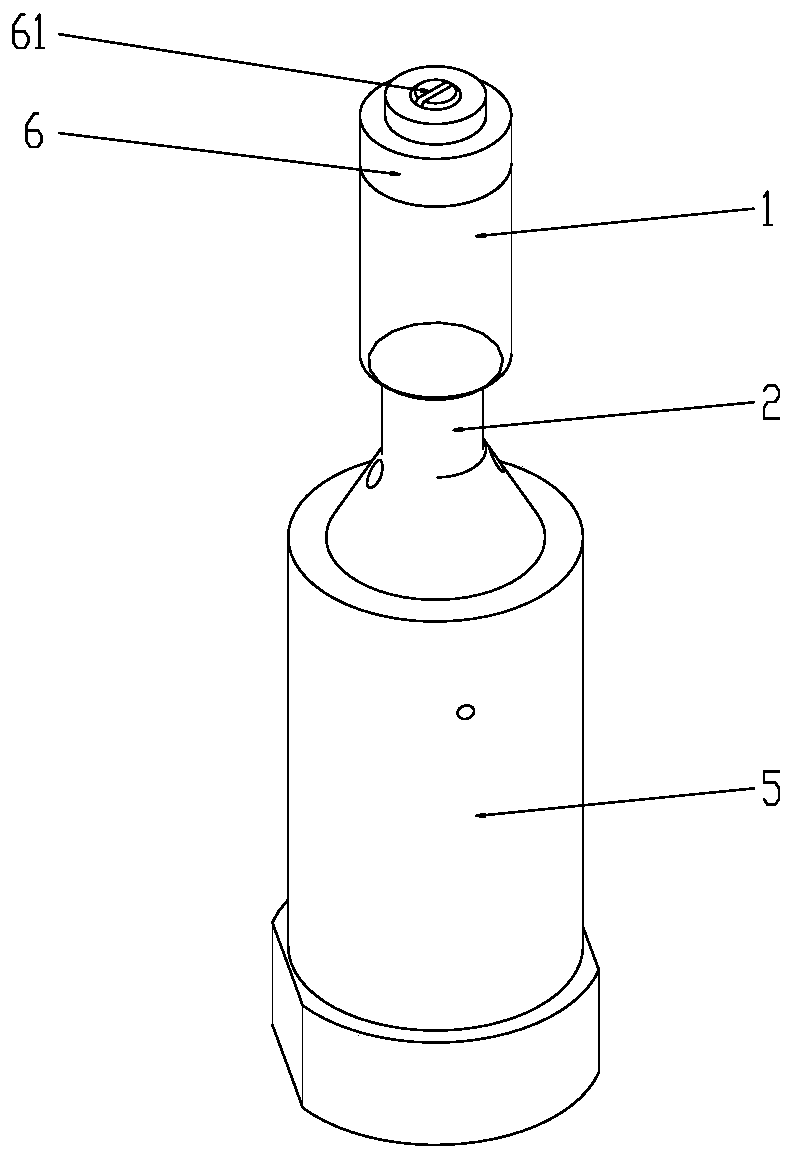

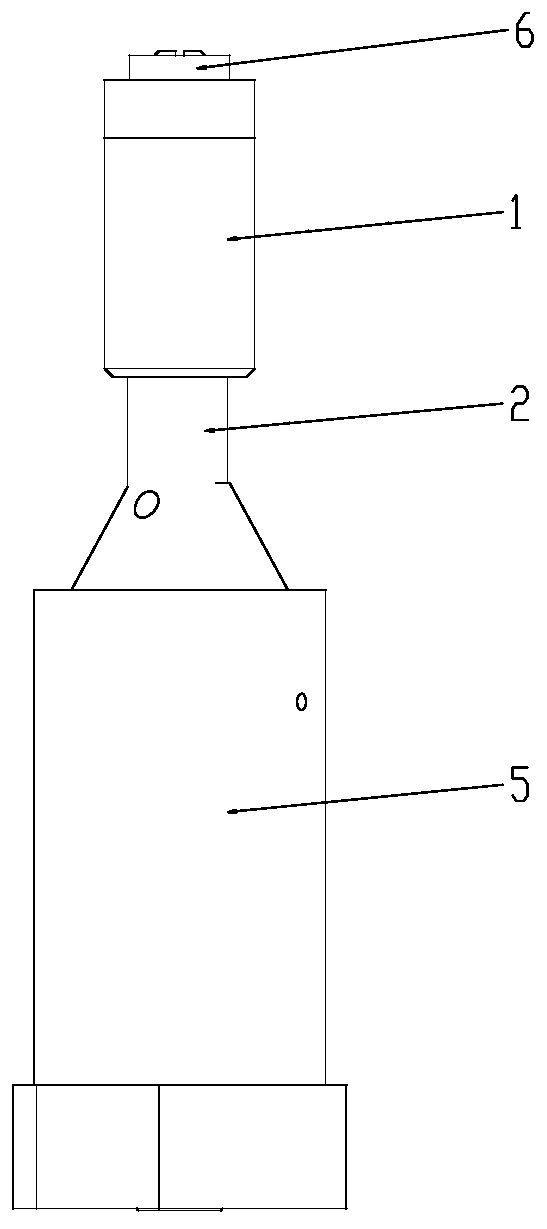

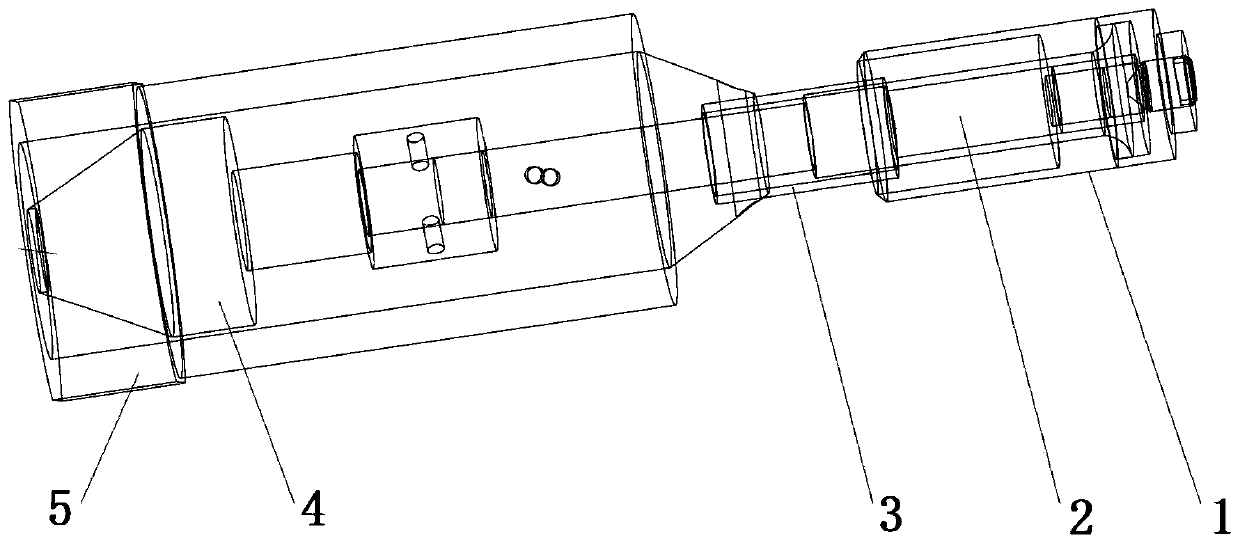

[0029] Refer to eg 1 to Figure 6 , The present application provides an auxiliary equipment for sample surface treatment, including a graduated cylinder 1 , a screw 2 , a nut 3 , a collet 4 and a knife holder 5 .

[0030] Wherein, the first end of the screw rod 2 is fixedly connected with the graduated cylinder 1, the second end of the screw rod 2 is fixedly connected with the tail of the collet 4, and the head of the collet 4 is used to clamp and fix the sample to be processed. The nut 3 is threadedly connected with the screw rod 2 , and the first end of the nut 3 is sheathed in the index cylinder 1 . The knife rest 5 is a cavity structure with openings at both ends, the second end outer wall of the nut 3 is fixedly connected with the knife rest 5, and the ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com