A Rare Earth Soft Magnetic Alloy Directly Deposited by Laser and Its Magnetic Properties Regulation Method

A technology of laser direct deposition and soft magnetic alloy, applied in the fields of magnetic properties measurement, magnetic objects, magnetic materials, etc., can solve the problems of soft magnetic alloy controlled production line adjustment, magnetic reduction, limited processing space, etc., to improve the comprehensive application technology level , the effect of expanding the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] (1) Raw materials for preparing rare earth soft magnetic alloy powder according to the composition ratio, the composition is divided into by weight: Ni: 80.0 parts, Mo: 2.5 parts, Gd: 2.0 parts, Si: 1.0 parts, Fe balance;

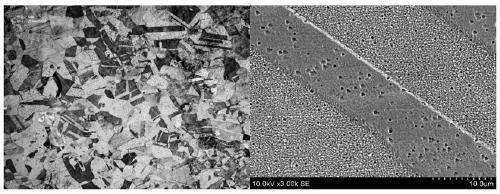

[0031] (2) Use hot inert gas atomization method (or rotating electrode atomization method) to prepare powder, use magnesia crucible to melt to alloy solution, and then pour into tundish to start high temperature supersonic inert gas atomization. The atomization medium is pure Argon, followed by powder sieving to finally obtain rare earth soft magnetic alloy powder with good sphericity and average particle size of 200 mesh;

[0032] (3) Place the rare earth soft magnetic alloy powder in a vacuum drying oven for 2 hours to dry at a temperature of 80°C and keep the vacuum at -0.06MPa to remove the influence factor of water vapor on defects;

[0033] (4) Select a Fe80NiSi cylinder with an inner diameter of 32mm as the carrier substrate, and fix it on the...

Embodiment 2

[0039](1) Raw materials for preparing rare earth soft magnetic alloy powder according to the composition ratio, the composition is divided into by weight: Ni: 80.0 parts, Mo: 2.5 parts, Gd: 2.0 parts, Si: 1.0 parts, Fe balance;

[0040] (2) Use hot inert gas atomization method (or rotating electrode atomization method) to prepare powder, use magnesia crucible to melt to alloy solution, and then pour into tundish to start high temperature supersonic inert gas atomization. The atomization medium is pure Argon, followed by powder sieving to finally obtain rare earth soft magnetic alloy powder with good sphericity and average particle size of 200 mesh;

[0041] (3) Place the rare earth soft magnetic alloy powder in a vacuum drying oven for 2 hours to dry at a temperature of 80°C and keep the vacuum at -0.06MPa to remove the influence factor of water vapor on defects;

[0042] (4) Select a Fe80NiSi cylinder with an inner diameter of 32mm as the carrier substrate, and fix it on the ...

Embodiment 3

[0048] (1) Raw materials for preparing rare earth soft magnetic alloy powder according to the composition ratio, the composition is divided into by weight: Ni: 80.0 parts, Mo: 2.5 parts, Gd: 2.0 parts, Si: 1.0 parts, Fe balance;

[0049] (2) Use hot inert gas atomization method (or rotating electrode atomization method) to prepare powder, use magnesia crucible to melt to alloy solution, and then pour into tundish to start high temperature supersonic inert gas atomization. The atomization medium is pure Argon, followed by powder sieving to finally obtain rare earth soft magnetic alloy powder with good sphericity and average particle size of 200 mesh;

[0050] (3) Place the rare earth soft magnetic alloy powder in a vacuum drying oven for 2 hours to dry at a temperature of 80°C and keep the vacuum at -0.06MPa to remove the influence factor of water vapor on defects;

[0051] (4) Select a Fe80NiSi cylinder with an inner diameter of 32mm as the carrier substrate, and fix it on the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com