Special equipment for multi-functional liquid rubber coating

A technology of liquid rubber and special equipment, applied in the fields of spray coating compositions based on natural rubber, synthetic rubber and asphalt, and coating compositions of water-based latex, can solve the problems of hard to buy, difficult to obtain raw materials, complicated design of spray gun system, etc. , to achieve the effect of reducing the cost of raw materials, easy availability of raw materials and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

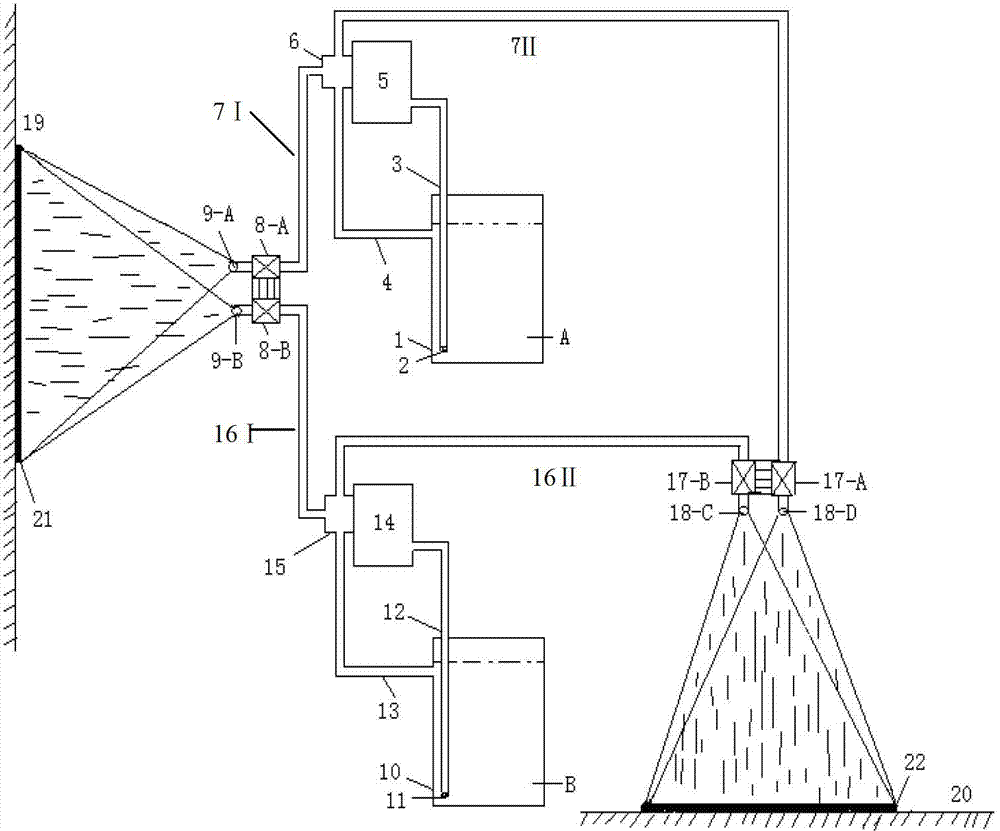

Method used

Image

Examples

Embodiment 1

[0035] The preparation and application of embodiment 1, liquid rubber paint

[0036] 1 Process and preparation:

[0037] 1. Process: preparation of component A rubber asphalt emulsion;

[0038] (1) Preparation of natural rubber latex and synthetic rubber latex: When the solid content of the purchased rubber latex is lower than 48-65%, the low-temperature extraction method is used to extract natural rubber anionic latex with a solid content greater than 48-65% and synthetic rubber latex Rubber anionic emulsion, and then put the emulsion into a reaction kettle and heat it up to 20-40°C for later use.

[0039] ⑵ Preparation of asphalt emulsion:

[0040] Add 100 parts by weight of No. 80-120 asphalt to the emulsified asphalt equipment and keep it at 130°C; add 20-45% of water and 3.0-5.0% of anionic surfactant at a temperature of 40-70°C and perform high-speed shearing Stir to prepare anionic emulsified asphalt with a solid content of 50.0-75.0%.

[0041] (3) Preparation of ca...

Embodiment 2

[0055] Embodiment 2, spraying on the cement-based surface

[0056] Material preparation: Preparation of component A: 100kg of rubber asphalt emulsion, 19.30kg of chloroprene rubber latex to be improved; 45kg of asphalt; 2.0kg of carbon black; 1.0kg of porcelain powder; rosin soap 0.90kg, synthetic fatty acid soap as surfactant 0.80kg, alkyl sulfonate 0.50kg; dispersant TH-904 0.10kg, naphthalene sulfonate formaldehyde condensate 0.30kg, CD-4 0.10kg, water as the balance; obtained component A improved chloroprene A rubber asphalt emulsion with a total solid content of 60.35% of diene rubber asphalt; the preparation method is the same as in Example 1.

[0057] The coagulant of component B is 12% calcium chloride-composite aluminum-iron polymer coagulant (calcium chloride content 94-97%, aluminum-iron polymer metal salt 3-6%), and the preparation method is the same as in Example 1.

[0058] Spraying equipment process method: with embodiment 1;

[0059] Test results: the surface...

Embodiment 3

[0060] Embodiment 3, spraying on the base surface of wooden board

[0061] Material preparation: A component preparation: 100kg rubber asphalt emulsion, 37.5kg of chloroprene rubber latex; 35.0kg of asphalt; 2.0kg of liquid carbon black; 0.55kg of surfactant rosin soap, 0.5kg of synthetic fatty acid soap, alkylsulfonate salt 0.2kg, alkyl aryl sulfate 0.2kg, α-naphthalenesulfonate alkylsulfonate 0.30kg; dispersant naphthalenesulfonate formaldehyde condensate 0.20kg, CD-40.20 water as the balance; obtained The preparation method of the chloroprene rubber asphalt emulsion with a total solid content of 57.9% of component A is the same as in Example 1.

[0062] Component B coagulant 6.0% calcium chloride, sodium chloride, composite aluminum-iron polymer polyvalent metal salt coagulant (calcium chloride content 91.0-95.0%, sodium chloride 1.0-3.0%, aluminum-iron polymer metal salt 2.0~6.0%).

[0063] Spraying equipment process method: the design capacity ratio of A and B pumps is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com