Cloth tailoring device for garment processing

A cutting device and cloth technology, which is applied in the field of garment processing, can solve the problems that cloth is easy to shrink under force, cutting quality cannot be guaranteed, and it is unfavorable for mass processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

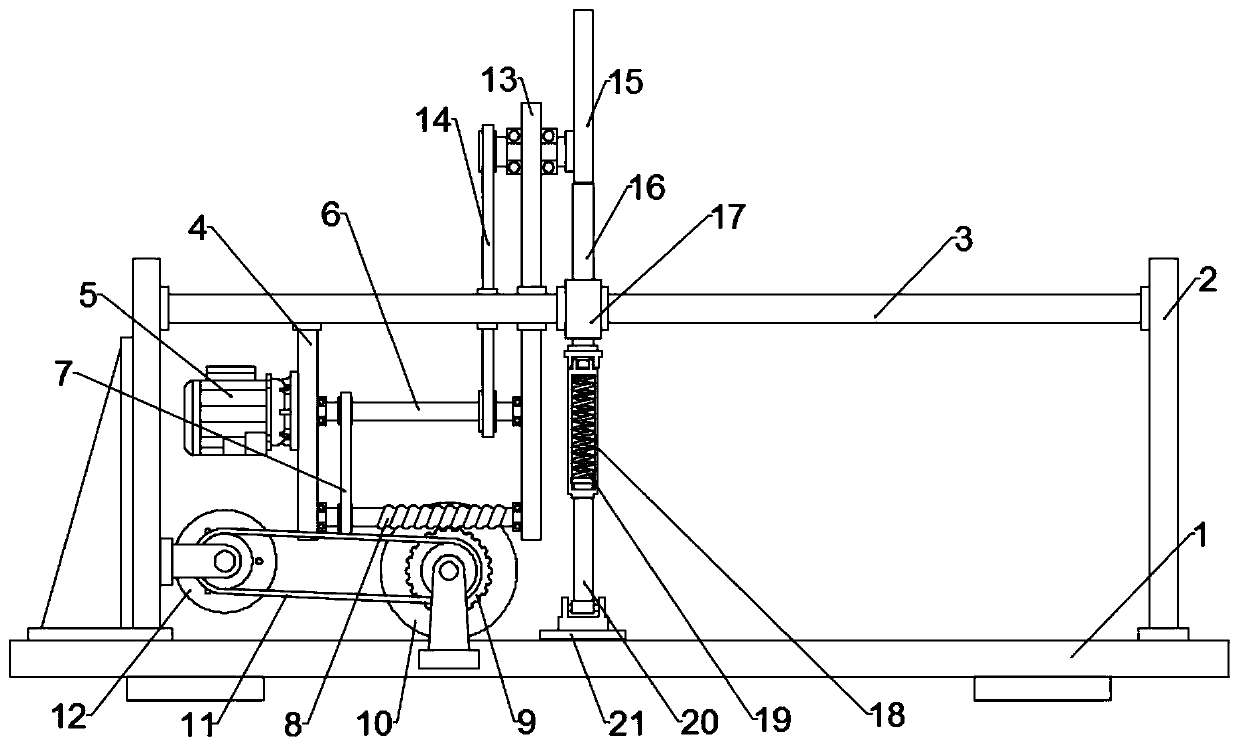

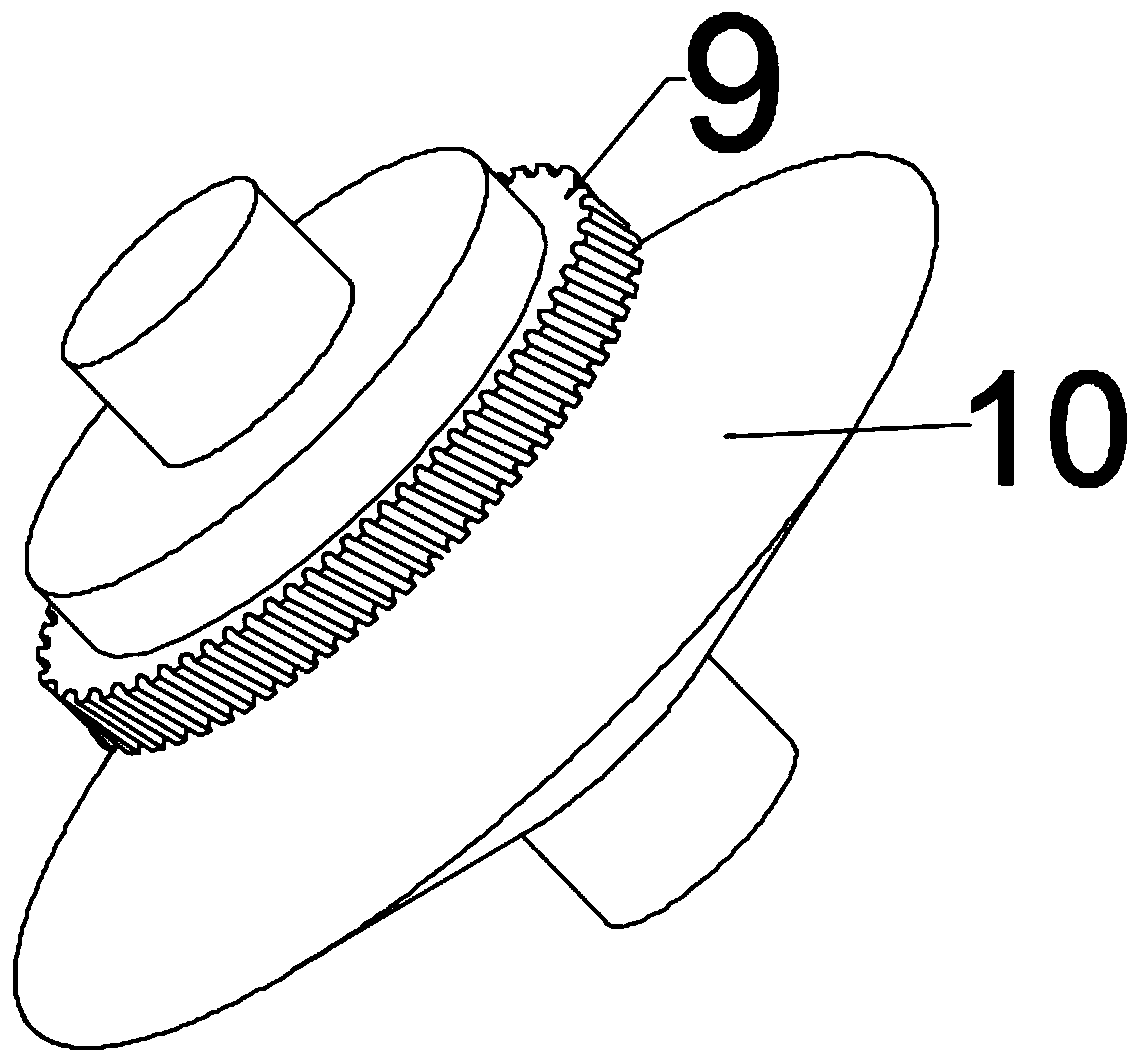

[0021] see Figure 1~3 , in an embodiment of the present invention, a cloth cutting device for garment processing includes a base plate 1, a top beam 3 fixed above the base plate 1 through side plates 2, an integrated cutting and winding assembly and a tensioning assembly; specifically, the The bottom of one side of the top beam 3 is fixedly connected with a suspender 4, and the upper flange of the suspender 4 is equipped with a servo motor 5 connected to a power supply and a switch through a wire. The output end of the servo motor 5 is connected to the output shaft 6, and the output shaft 6 passes through the first The transmission member 7 is connected to the cutting and winding integrated assembly and the third transmission member 14 is connected to the tensioning assembly, and the servo motor 5 simultaneously drives the cutting and winding assembly to wind the tube while cutting, and the tensioning assembly stretches the cloth to be cut. Prevent the knife from happening. ...

Embodiment 2

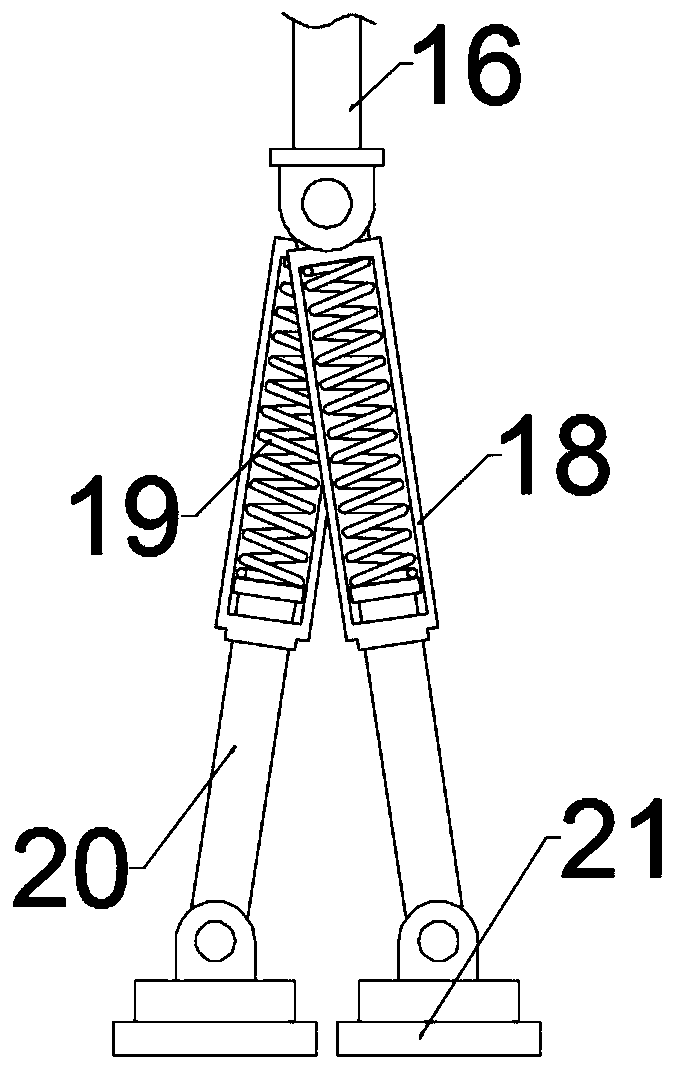

[0027] In order to further explain the elastic mechanism in the above-mentioned fabric cutting device for garment processing, the application provides another embodiment, a fabric cutting device for garment processing, the elastic mechanism includes upper ends hinged to each other and jointly rotated and arranged on a movable rod The swing sleeve 18 at the lower end of 16, the spring 19 arranged inside the swing sleeve 18, is sleeved on the driven rod 20 at the bottom of the swing sleeve 18, wherein the pressure block 21 is hinged at the lower end of the driven rod 20, and the upper end of the driven rod 20 is against the The lower end of the spring 19 is connected, and the upper end of the spring 19 abuts against the top of the swing sleeve 18, and the elastic connection between the driven rod 20 and the swing sleeve 18 is realized by the spring 19, so as to prevent the cloth from being damaged by rigid stretching.

[0028] According to the specific description of the above em...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com