Light steel keel type corner wall formwork reinforcing system

A light steel keel and corner technology, applied in the direction of formwork/formwork/work frame, formwork/formwork/work frame connection, on-site preparation of building components, etc., can solve the problem that adjacent horizontal bars are difficult to ensure that they are perpendicular to each other. , It is difficult to guarantee the verticality of the board surface, and the space for the pulling operation is limited, so as to achieve the effect of high assembling and disassembling efficiency, simple structure and convenient assembling and disassembling operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

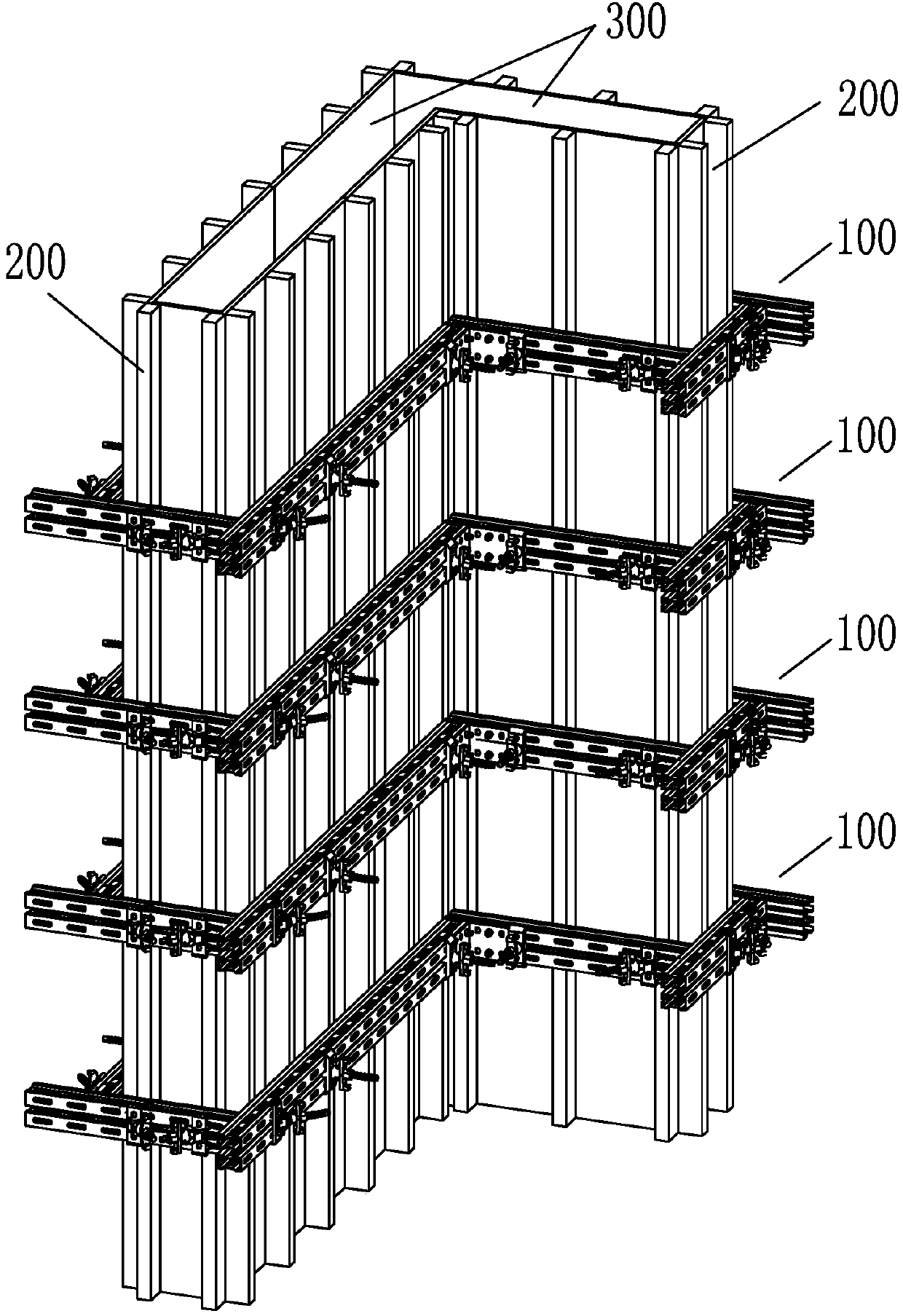

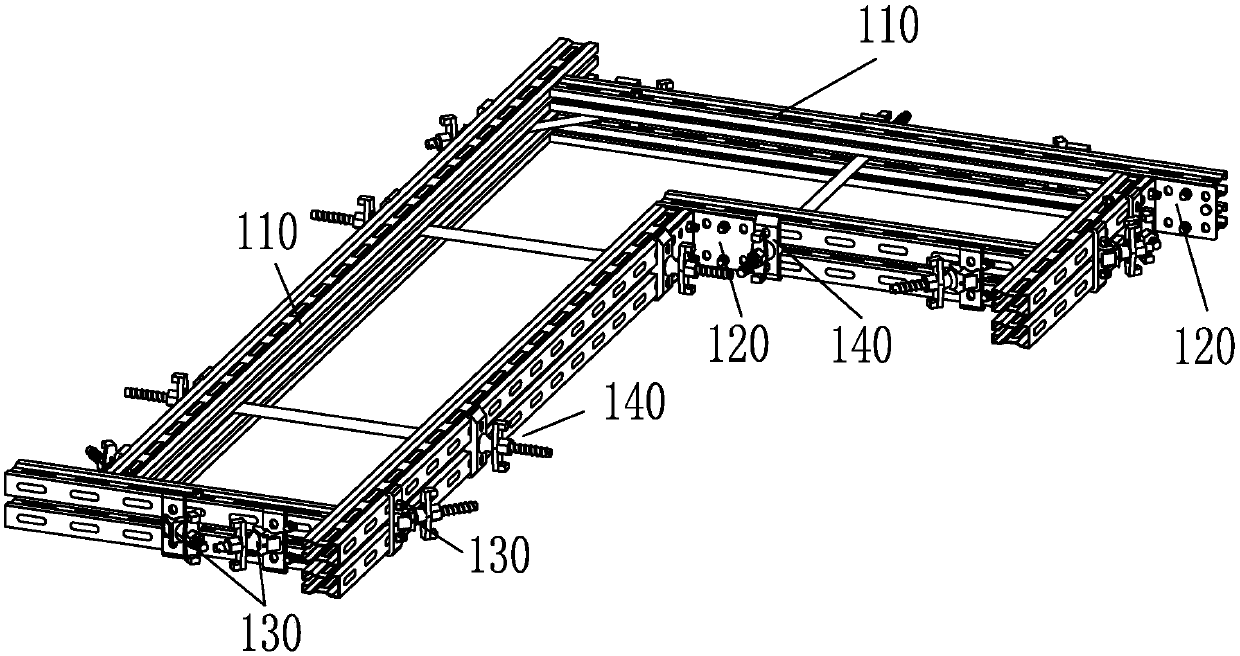

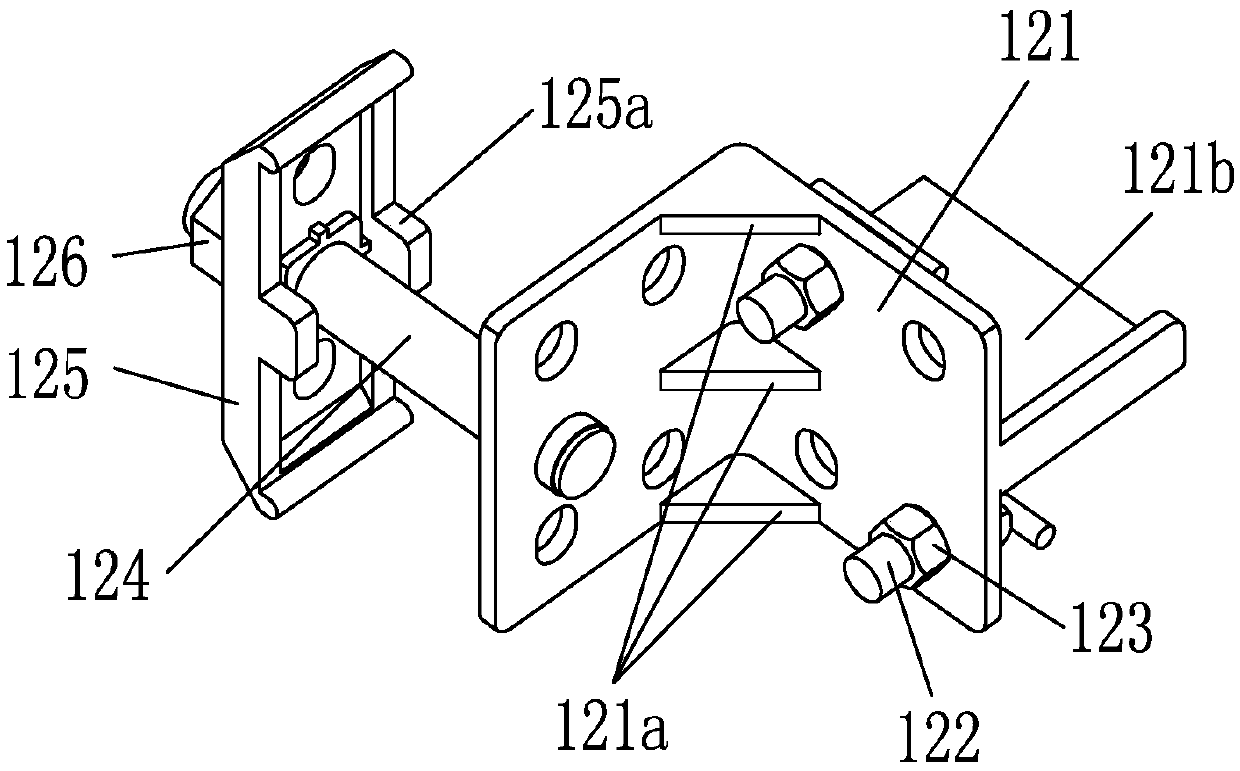

[0037] Example 1, see figure 1 , figure 2 , a light steel keel type corner wall formwork reinforcement system, which consists of a plurality of vertically spaced back corrugated reinforcement frames 100 to form a clamp-type fastening to the vertical back corrugated 200 of the corner wall formwork; the inner side of the vertical back corrugated 200 is against the On the template 300; the back corrugated reinforcement frame 100 includes a plurality of horizontal bars 110; the front end of one of the two adjacent horizontal bars 110 abuts against the side of the other outer horizontal bar 110 at the corner, and the two abutting against each other The adjacent horizontal bars 110 are fixedly connected to each other through the right angle guarantee device 120 to form a state perpendicular to each other; except for the inner wall corners, two adjacent horizontal bars 110 perpendicular to each other are reinforced by corner pair pullers 130; two parallel horizontal bars The bar 11...

Embodiment 2

[0044] Example 2, see Figure 17 , Figure 18 , the upper and lower edges of the two right-angled sides of the right-angled angle iron body 121 are formed with flanging 121c, so that the two right-angled sides all form a channel steel shape, and the groove bottom of the right-angled side is fitted and fixed on the outer surface of the corresponding horizontal bar 110, The side wall of the right-angled side groove formed by the flange 121c is buckled on the upper and lower sides of the corresponding horizontal bar 110, and the corresponding side walls of the two right-angled sides are integrated; the horizontal bar 100 is composed of a single C-shaped light steel 111; The insert plate 121b formed on the right angle side of the angle iron body 121 is inserted into the second bar-shaped hole 111g on the bottom straight section 111b of the C-shaped light steel 1111 corresponding to the horizontal bar for passing the first T-bolt 134 Middle; the positioning tongue 131c on the corn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com