Mechanical performance testing platform for laser scanning galvanometer motor

A laser scanning vibrating mirror and testing platform technology, which is applied in the testing of mechanical components, testing of machine/structural components, measuring devices, etc., can solve the problems of no scanning vibrating mirror motor mechanical performance testing platform, etc., and achieve effective mechanical performance testing , the size is constant, and the force arm remains constant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to make the technical means and effects realized by the present invention easy to understand, the present invention will be described in detail below in conjunction with the embodiments and accompanying drawings.

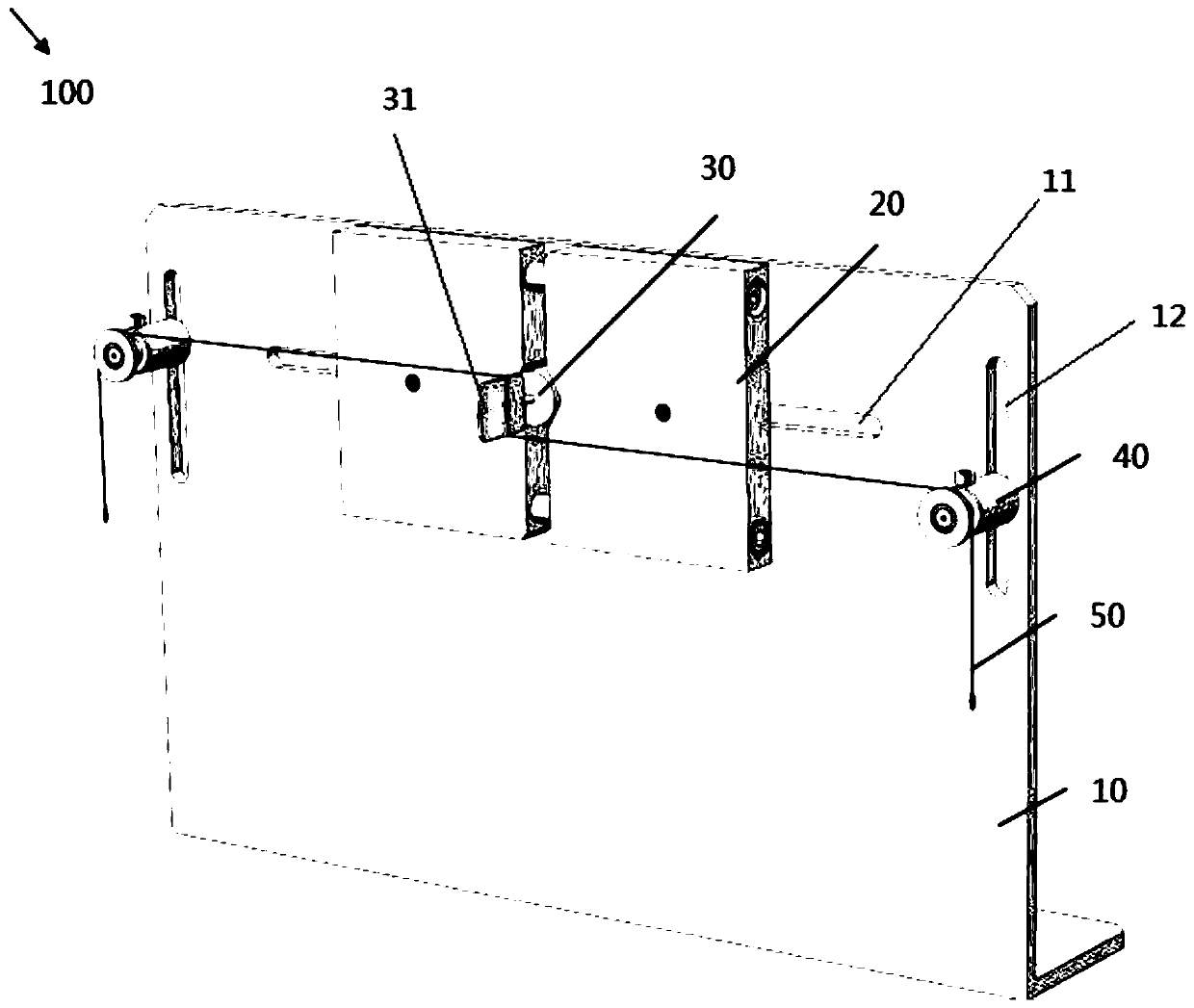

[0016] figure 1 It is a schematic diagram of the overall structure of the mechanical performance testing platform of the laser scanning vibrating mirror motor in the embodiment of the present invention.

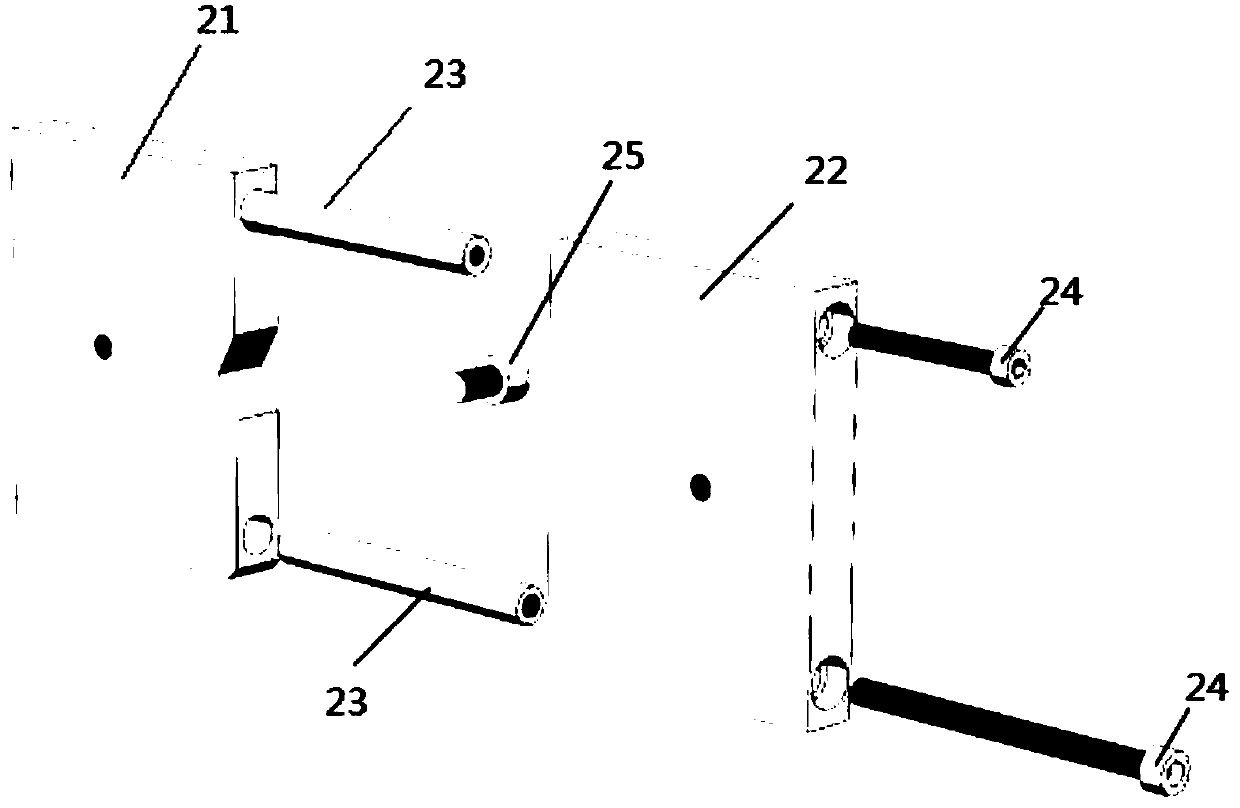

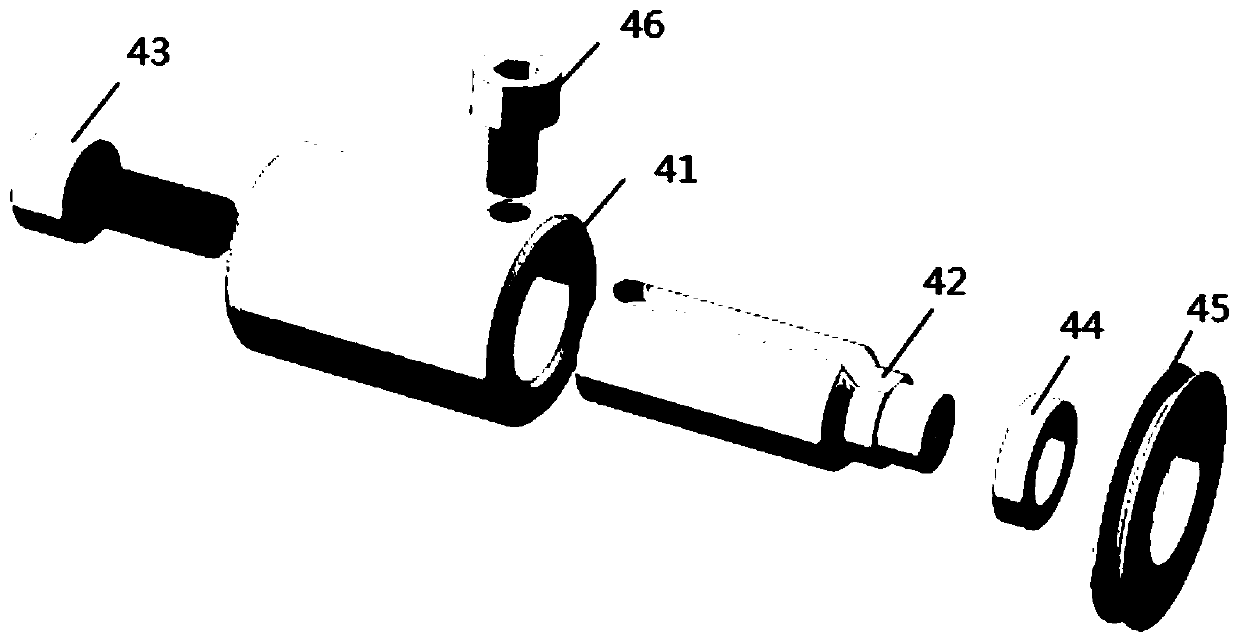

[0017] Such as figure 1 As shown, a mechanical performance testing platform 100 of a laser scanning vibrating mirror motor in this embodiment has a mounting base 10 , a vibrating mirror motor clamping mechanism 20 , a vibrating mirror motor 30 , a pulley adjusting mechanism 40 and a thin wire 50 .

[0018] The mounting seat 10 is L-shaped, and has a horizontal bottom plate placed on the ground and a vertical plate connected to the horizontal bottom plate. A horizontal guide groove 11 is provided at the upper center of the vertical plate, and a hori...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com