led display

A technology of LED display screen and elastic resin, which is applied in the direction of identification devices and instruments, which can solve the problems of chipping, the impact strength of the protective resin layer cannot meet the use requirements, and the rubber surface is easy to reflect light, so as to buffer external impact and improve the durability. Scratch resistance and edge chipping performance, good impact strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

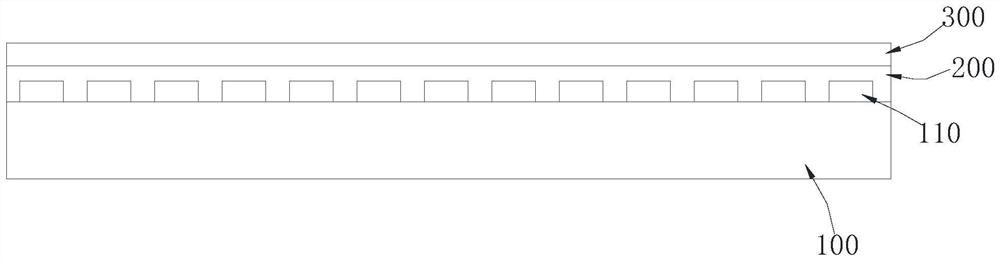

Image

Examples

specific Embodiment 1

[0111] 1. Take a P1.2 small-pitch LED module, the length is 181.54mm, the width is 162.48mm, the height of the LED lamp bead is 1mm, and a 5mm wide craft edge is reserved around the module, and the small space is cleaned with alcohol and non-woven fabric. Spacing LED module surface.

[0112] 2. Prepare transparent epoxy resin glue with the mass ratio of epoxy resin glue A:B as 3:1, and stir mechanically for 5 minutes. Cover the electronic components on the back of the LED module with adhesive tape before gluing to prevent the glue from contaminating the IC surface during the gluing process. This example adopts the method of front-side gluing. Place the LED module light face up on a hollow fixture to ensure that the light surface has a good level, and then pour a sufficient amount of transparent glue on the horizontal LED light surface. The treated PC film is withheld on the glue surface, and the glue liquid completely covers the lamp surface by squeezing, and the overflowing...

specific Embodiment 2

[0120] 1. Take a P1.2 small-pitch LED module, the length is 181.54mm, the width is 162.48mm, the height of the lamp bead is 1mm, and a 5mm-wide craft edge is reserved around the module, and the small space is cleaned with alcohol and non-woven fabric LED module surface.

[0121] 2. Prepare transparent epoxy resin glue with the mass ratio of epoxy resin glue A:B as 3:1, and stir mechanically for 5 minutes. Cover the electronic components on the back of the LED module with adhesive tape before gluing to prevent the glue from contaminating the IC surface during the gluing process. This example adopts the method of pouring glue upside down. Take a PC film with a length of 25cm and a width of 25cm and treated with a release agent. Use tape to build a dam around the film to prevent the glue from flowing out of the film. Pour a sufficient amount of transparent glue on the horizontal PC film, and then place the LED module light surface. Buckle down on the glue, and make the glue con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com