Brush head assembly and electric toothbrush

A component and brush head technology, applied in dentistry, brushes, brush bodies, etc., can solve the problems of difficult insertion and removal, insufficient locking force of the drive shaft, and falling off of the brush head assembly, so as to achieve smooth and convenient stroke and convenient insertion and removal process. and smooth effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

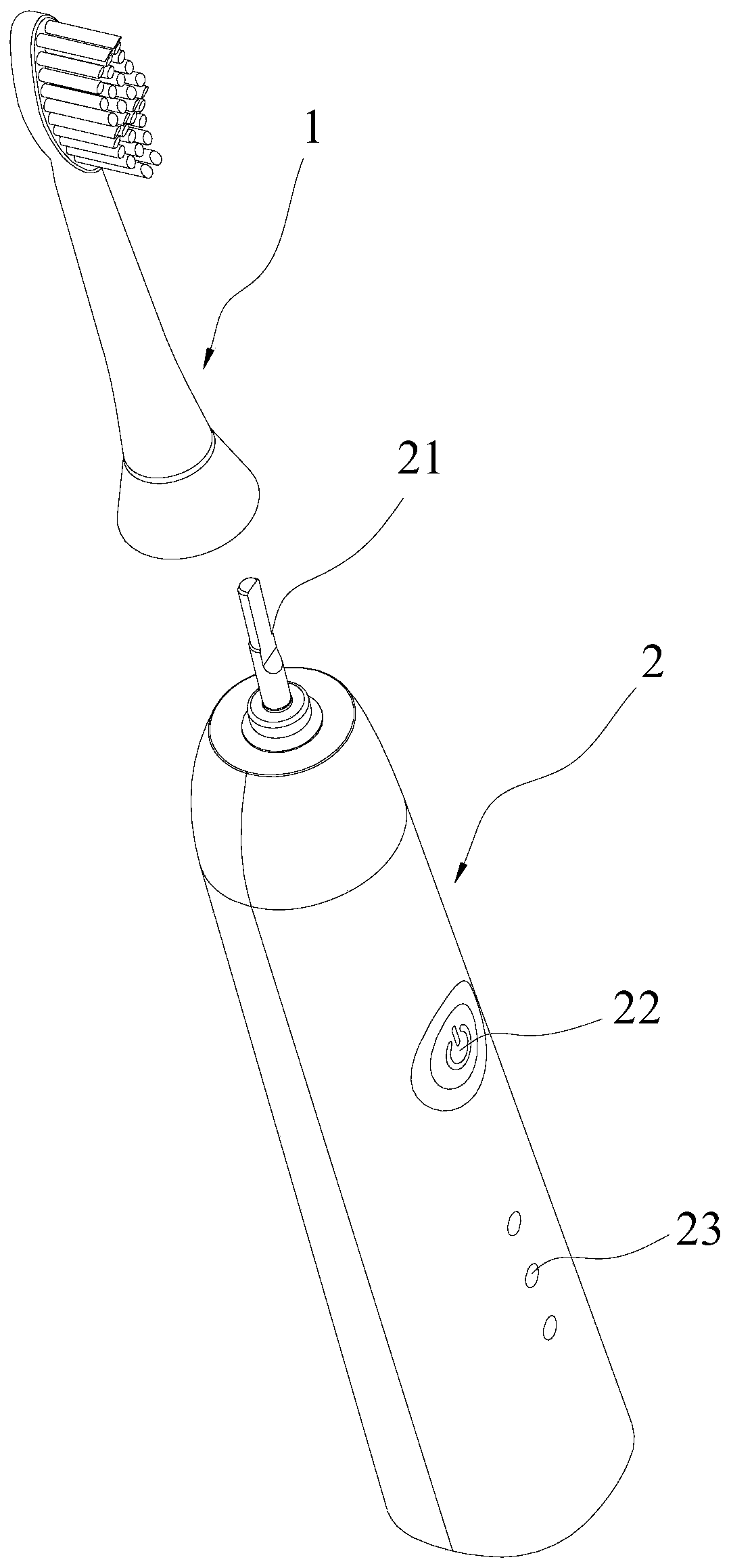

[0060] like figure 1 As shown, an electric toothbrush is disclosed in this example, and the electric toothbrush includes a handle assembly 2 and a brush head assembly 1; , a control board and a battery; the drive shaft 21 of the motor protrudes from the housing. The brush head assembly 1 can be inserted on the drive shaft 21. The housing is generally also provided with a power switch 22, an indicator light 23, etc., because they are not the improved parts in this example, so they are not described in detail.

[0061] The core inventive idea in this example is to improve the brush head assembly 1 so that it can be better locked and connected with the drive shaft 21. The brush head assembly 1 disclosed in the present application will be further specifically explained below in conjunction with the accompanying drawings.

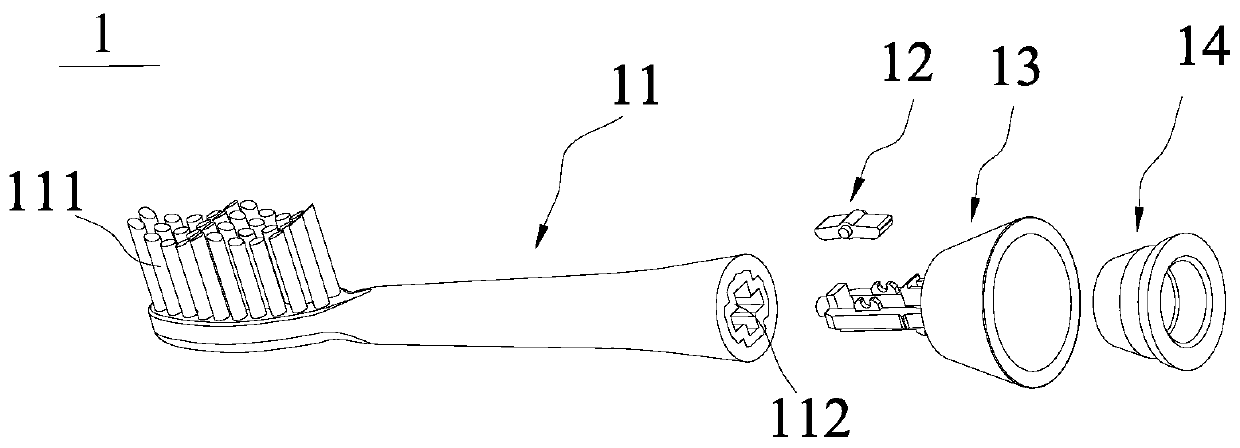

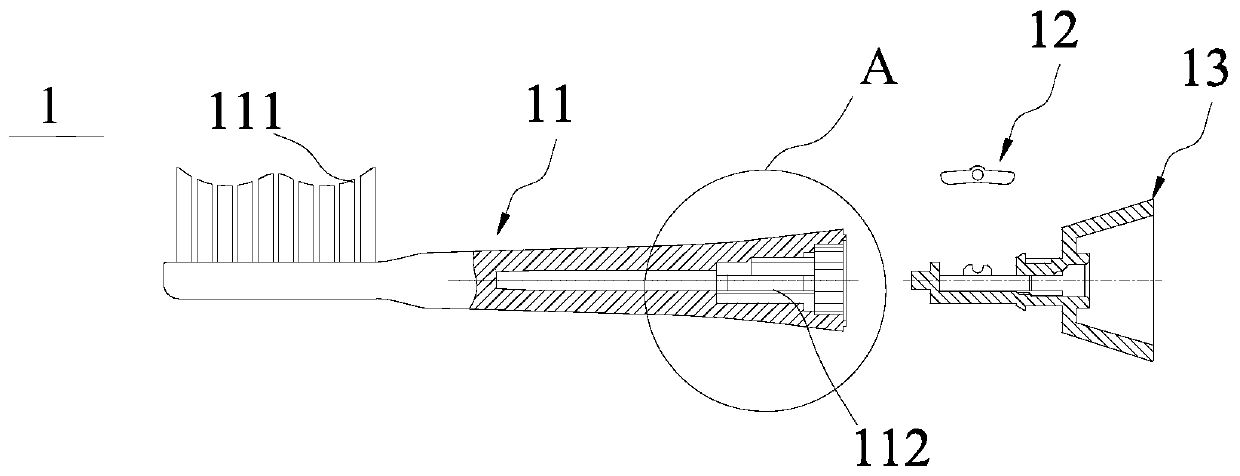

[0062] like figure 2 , image 3 As shown, the brush head assembly 1 disclosed in this example includes a brush head body 11, a coupling member 13 and a lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com