Semiconductor material production technology equipment

A production technology, semiconductor technology, applied in the direction of metal processing equipment, grinding/polishing equipment, grinding/polishing safety devices, etc., can solve problems such as outward splashing, wear and unevenness of internal components of the polishing machine, and achieve damage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

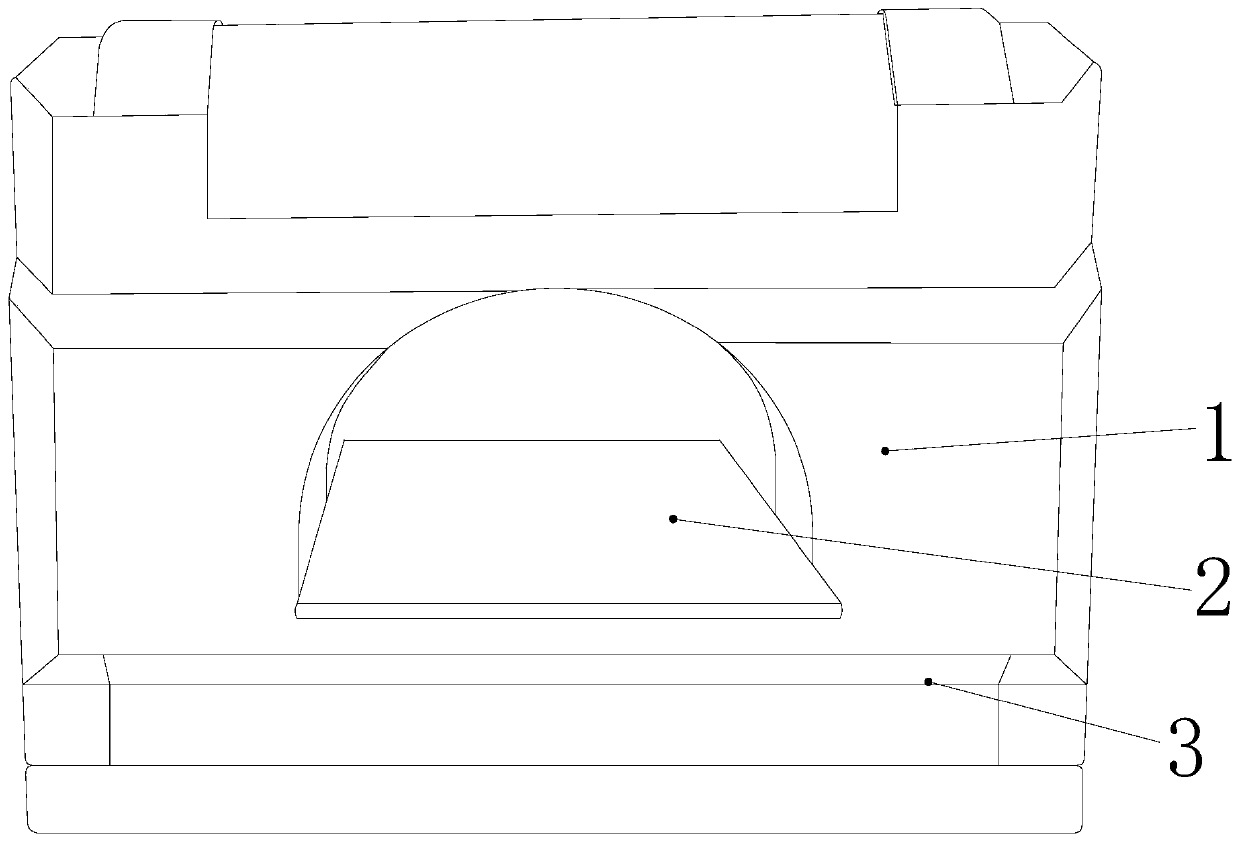

[0026] see Figure 1-Figure 6 , the present invention provides technical equipment for semiconductor material production, the structure of which includes a chip collecting device 1, a processing table 2, and a housing 3. The chip collecting device 1 is mechanically connected to the processing table 2, and the processing table 2 is arranged on the housing 3 in the center and penetrate the shell 3, the shell 3 is connected with the chip collecting device 1;

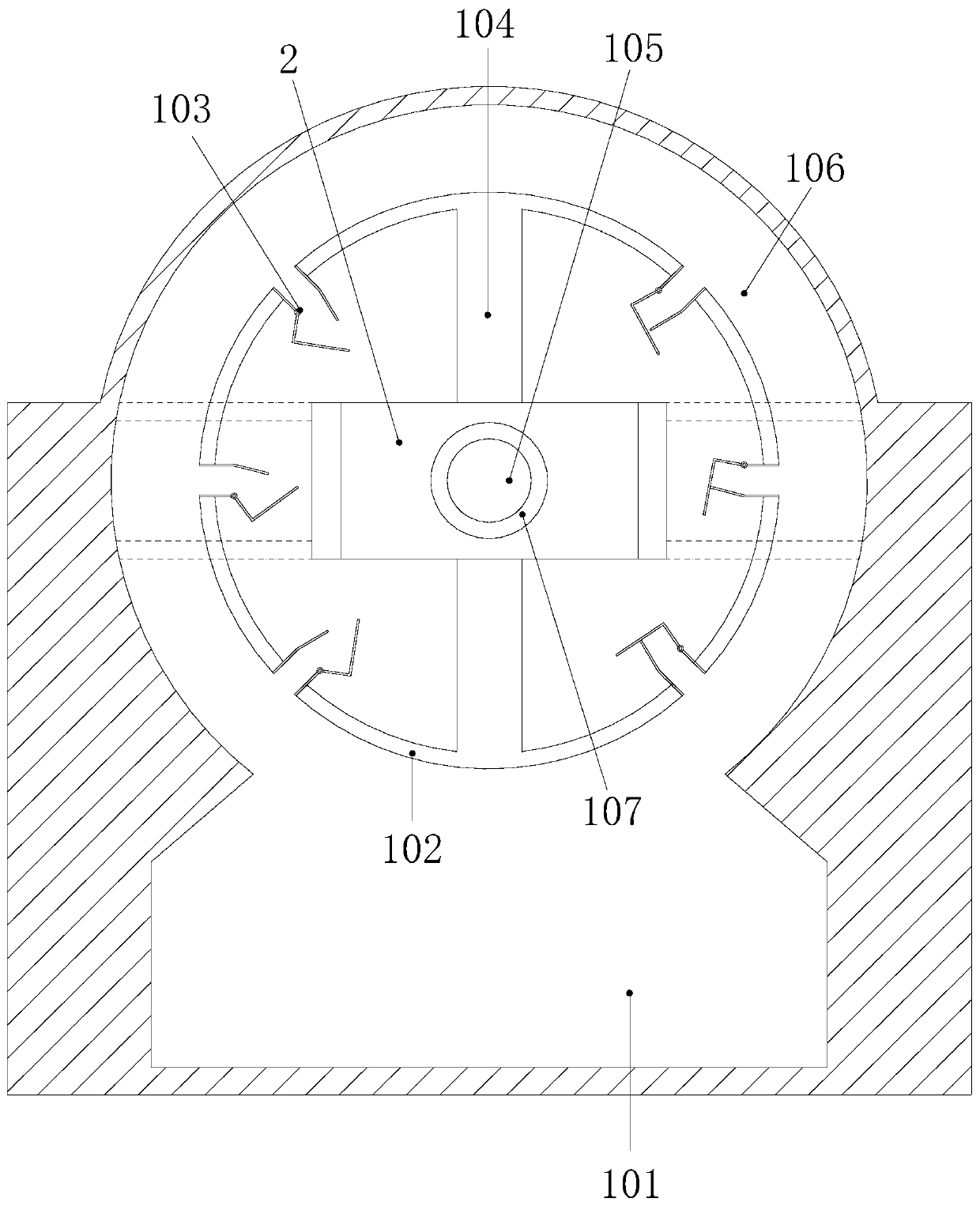

[0027] The chip collecting device 1 is composed of a chip collecting chamber 101, an annular wall plate 102, a chip feeding mechanism 103, a rotating rod 104, a central shaft 105, an annular channel 106, and a connecting shaft disk 107. The channel 106 communicates, and the annular channel 106 is connected with the annular wall plate 102. The chip feeding mechanism 103 is fixedly installed on the annular wall plate 102. There are more than four chip feeding mechanisms 103, and the The annular wall plate 102 is mechanically...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com