A method and device for comprehensively treating construction waste

A technology for comprehensive treatment of construction waste, applied in construction waste recycling, chemical instruments and methods, magnetic separation, etc., can solve the problems of reduced separation effect, inability to adsorb electromagnets, limited size of electromagnets, etc., and achieve the effect of improving separation effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

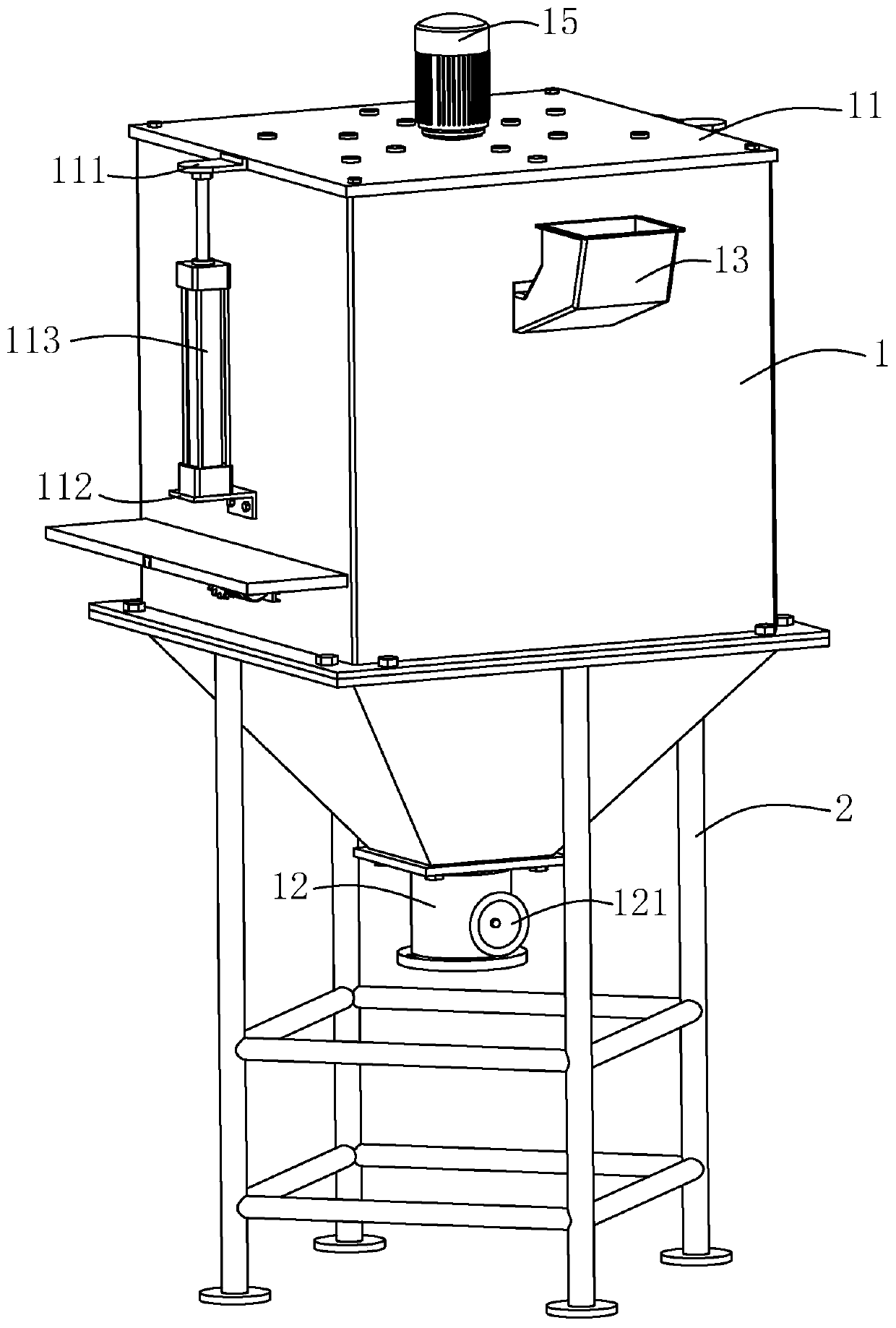

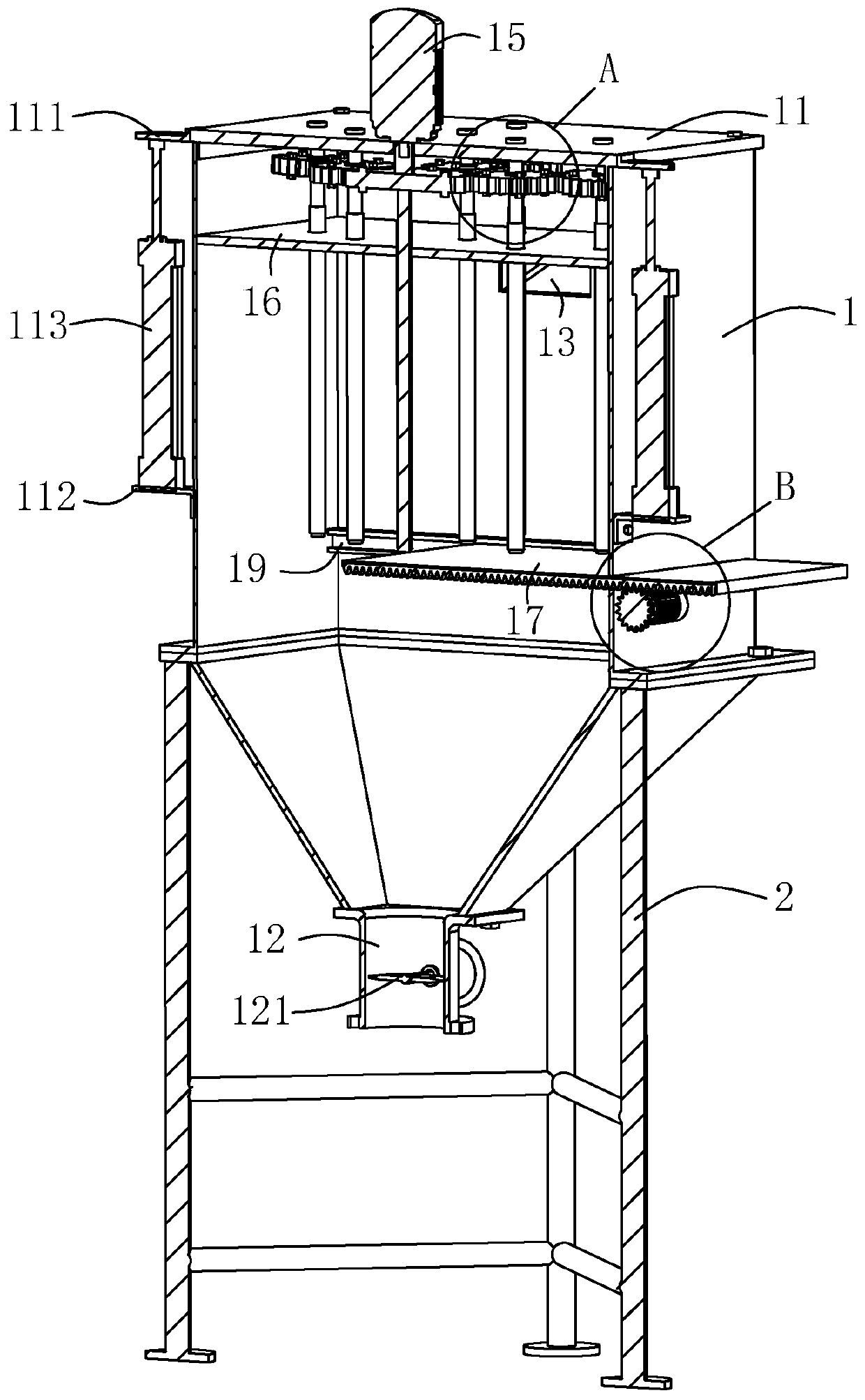

[0052] to combine figure 1 with figure 2 , a device for comprehensive treatment of construction waste, comprising a frame body 2, a storage hopper 1 is arranged on the frame body 2, a cover plate 11 is arranged on the storage hopper 1, a discharge pipe 12 is provided at the bottom of the storage hopper 1, and a discharge pipe 12 is arranged on the discharge pipe 12 A discharge switch 121 is provided. In this embodiment, the discharge switch 121 is set as a butterfly valve, which can control the flow rate and flow rate of the discharge.

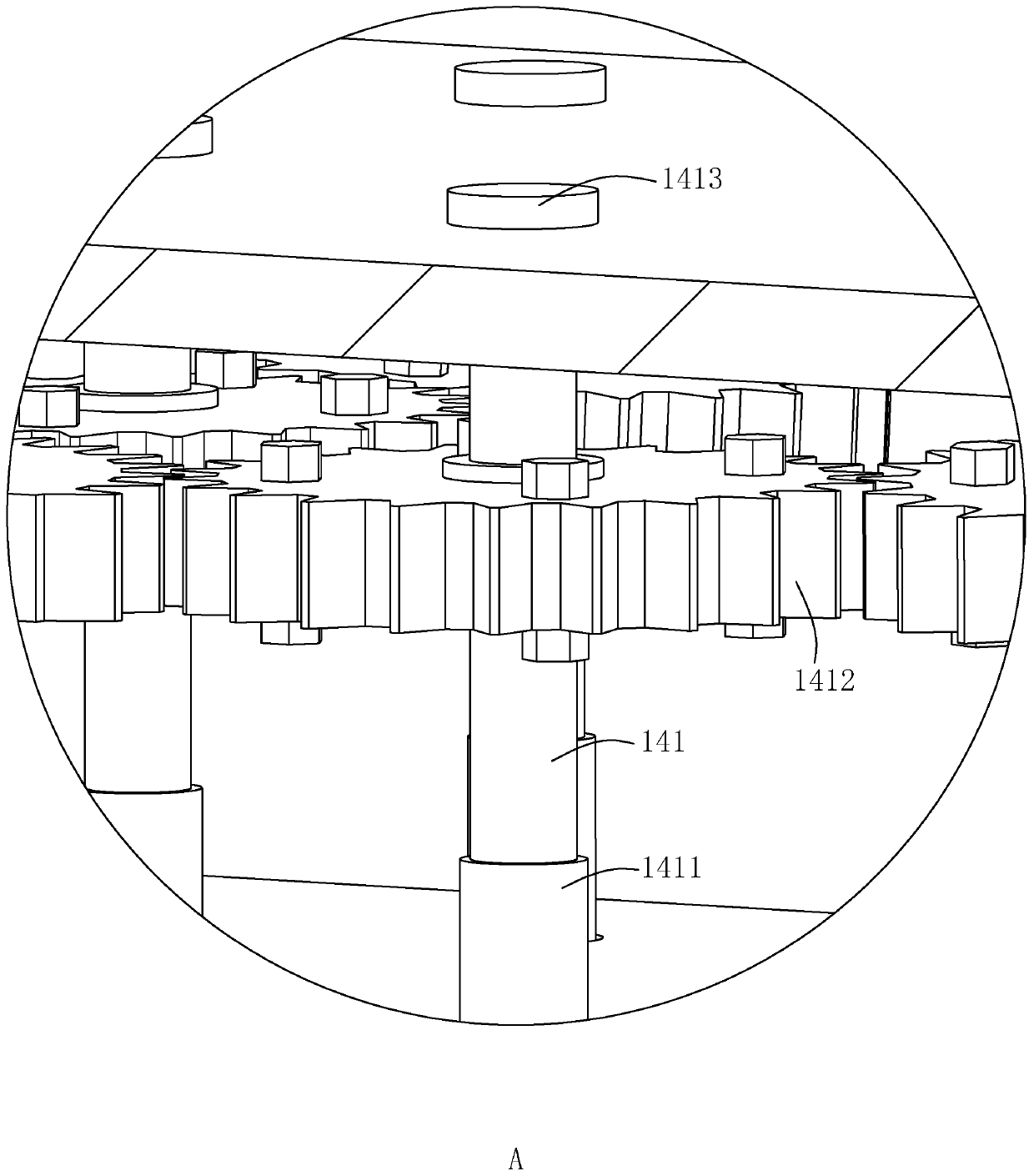

[0053] to combine figure 2 with Figure 5 , the cover plate 11 is provided with multiple sets of separation assemblies 14, the multiple sets of separation assemblies 14 are concentrically arranged with the center of the cover plate 11 as the center of the circle, each set of separation assemblies 14 includes a plurality of rotating shafts 141, and the ends of the plurality of rotating shafts A flange 1413 is provided, and the rotating sha...

Embodiment 2

[0062] A method for comprehensively processing construction waste,

[0063] S1: The construction waste is crushed with a crusher, and the construction waste is repeatedly crushed three times; the construction waste is crushed more thoroughly.

[0064] S2: Transport the crushed construction waste to the comprehensive construction waste treatment device through a large-inclination inclined belt conveyor.

[0065] S3: Separation of metals from buildings through a comprehensive treatment of construction waste; making the metals in construction waste more thoroughly separated.

[0066] S301: put the construction waste into the feeding chute 13, and move the construction waste to the opening and closing plate 17;

[0067] S302: Start the first motor 15, so that the driving gear 151 drives a plurality of rotating gears 1412 to rotate, and the rotating gear 1412 drives a plurality of rotating shafts 141 to rotate at the same time, and the rotating shaft 141 absorbs the metal in the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com