Rotary knife device capable of automatically compensating

An automatic compensation and rotary knife technology, applied in metal processing and other directions, can solve the problems of manual adjustment of cutting blades, and achieve the effect of automatically compensating for blade gap, improving utilization rate and improving work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

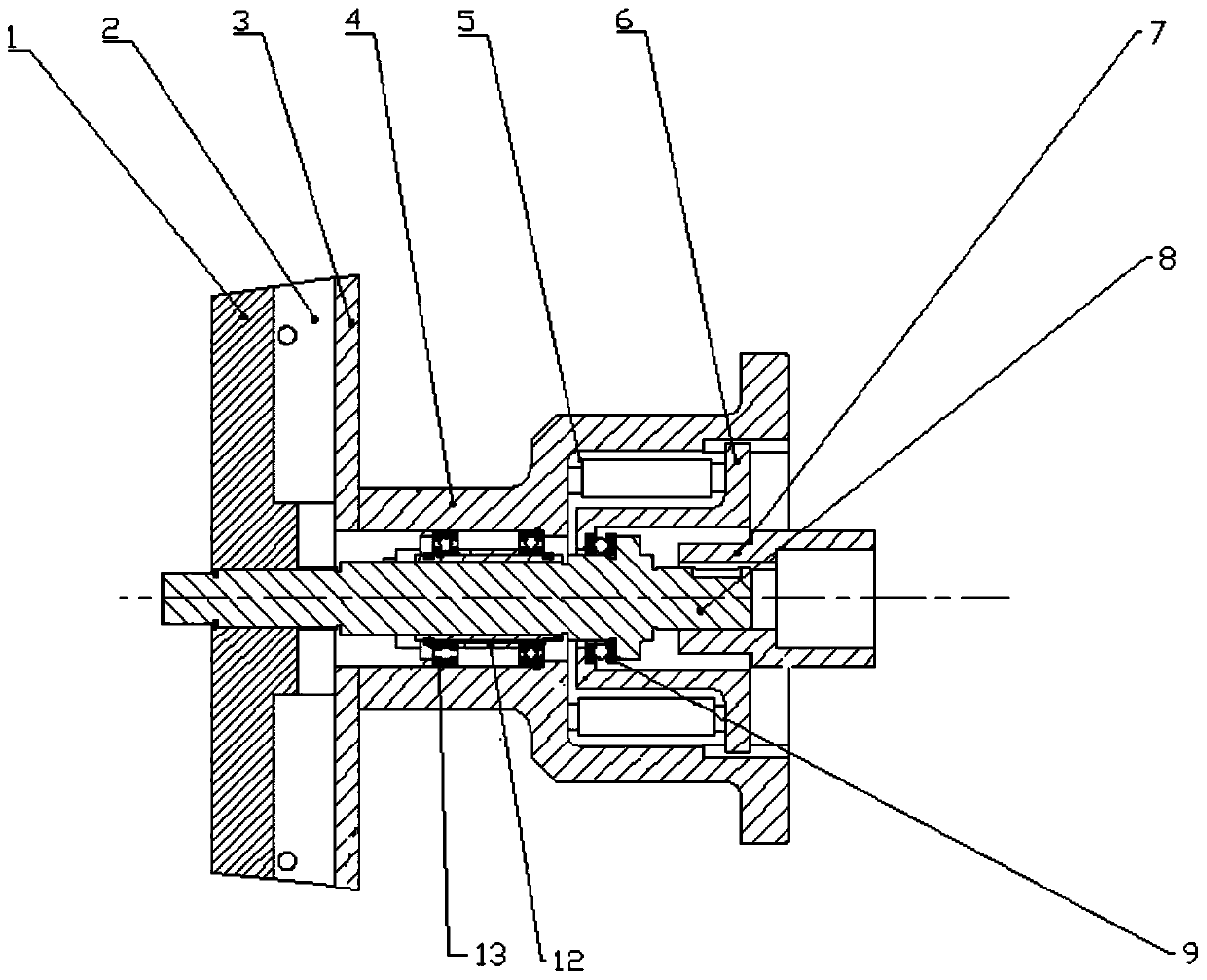

[0029] This embodiment provides a rotary knife device capable of automatic compensation, including a knife handle 1, a blade 2, a cutter head 3, a mounting seat 4, a thrust member 5, a bearing seat 6, a coupling 7, a rotating shaft 8, and a thrust ball bearing 9. Sleeve 12, deep groove ball bearing 13.

[0030] Such as figure 1 As shown in the schematic diagram of the structure of Embodiment 1 of the present invention, one end of the rotating shaft 8 is provided with a handle 1, and the handle 1 can be fixed on the front end of the rotating shaft 8 by threaded connection, and several blades 2 are arranged on the handle 1. The other end of the shaft 8 is a shaft coupling 7, and the shaft coupling 7 provides rotational power to make the blade 2 rotate and work.

[0031] The cutter head 3 and the mounting seat 4 are fixed on the machine tool, and the cutter head 3 and the blade 2 are next to each other.

[0032] There is a sleeve 12 in the middle of the rotating shaft 8, and de...

Embodiment 2

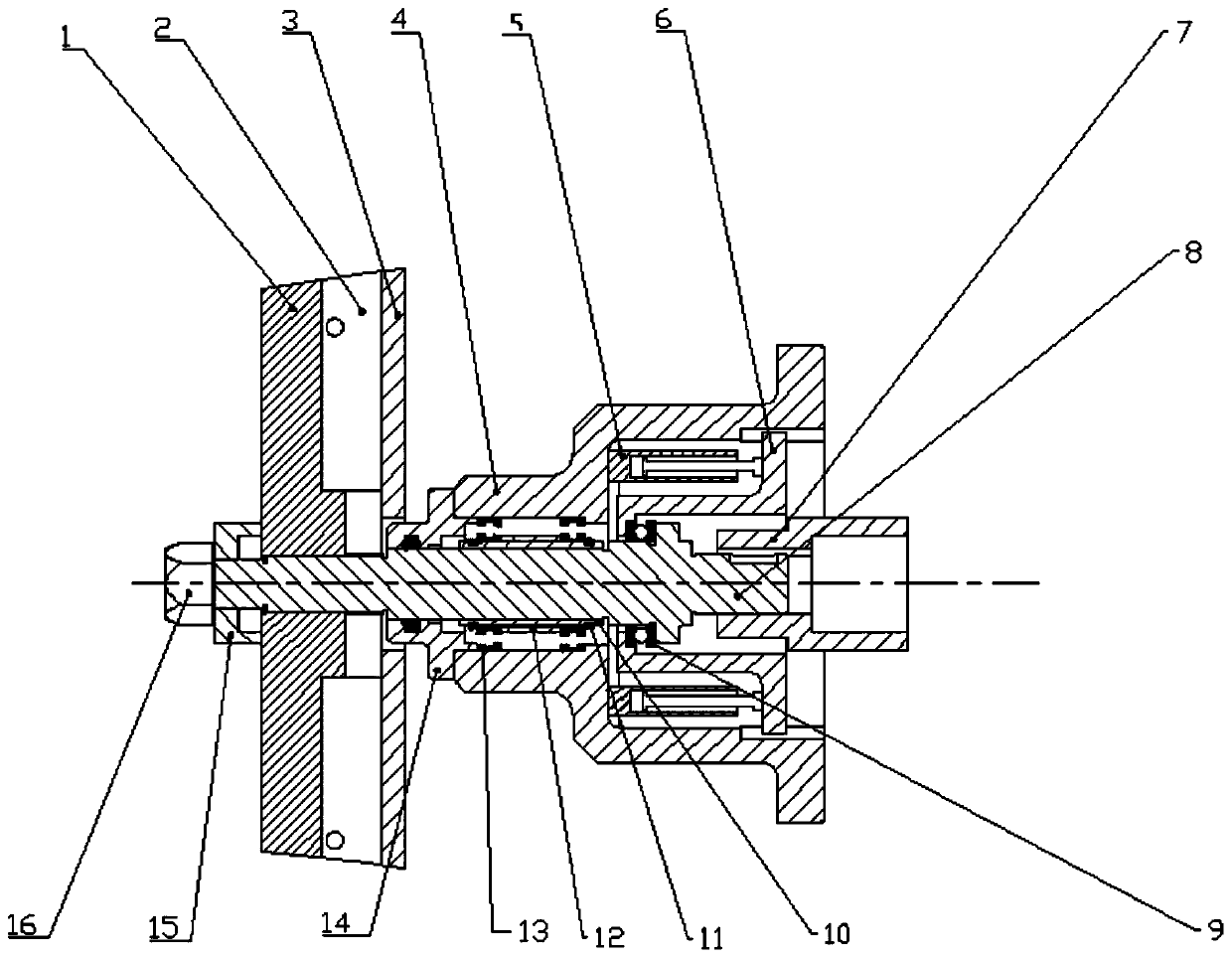

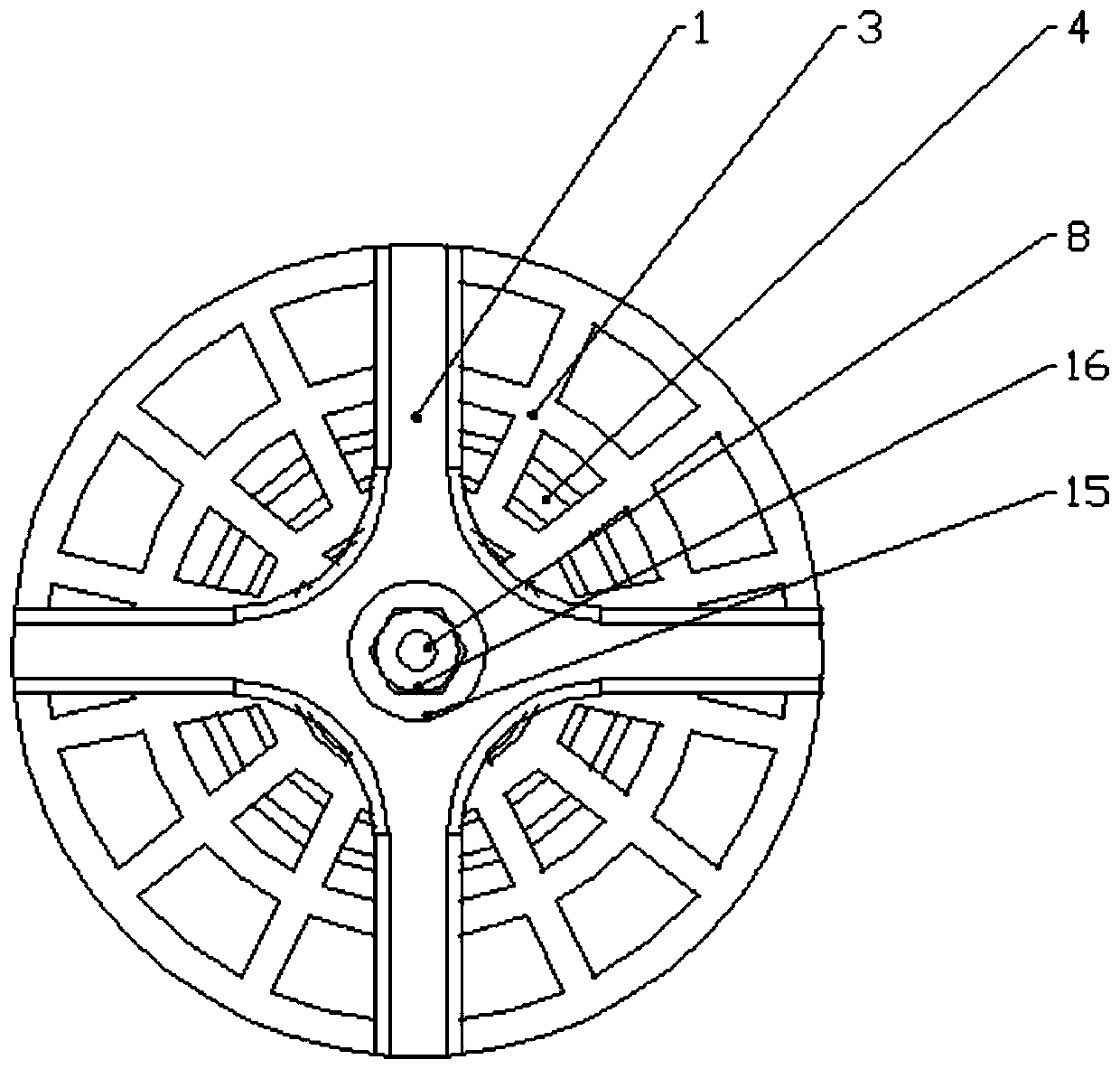

[0038] Embodiment 2 provides a rotary knife device capable of automatic compensation, including a knife handle 1, a blade 2, a cutter head 3, a mounting seat 4, a thrust member 5, a bearing seat 6, a coupling 7, a rotating shaft 8, and a thrust ball bearing 9, shaft sleeve, 10, thrust ring 11, sleeve 12, deep groove ball bearing 13, dustproof cover 14, nut sleeve 15, fixed nut 16.

[0039] Such as figure 2 As shown in the schematic diagram of the structure of Embodiment 2 of the present invention, one end of the rotating shaft 8 is provided with a knife handle 1, and the knife handle 1 can be fixed on the front end of the rotating shaft 8 through threaded connection. The other end of the shaft 8 is a shaft coupling 7, and the shaft coupling 7 provides rotational power to make the blade 2 rotate and work.

[0040] The cutter head 3 and the mounting seat 4 are fixed on the machine tool, and the cutter head 3 and the blade 2 are next to each other.

[0041] The knife handle 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com