Flexible meshing pair of single screw compressor

A single-screw compressor and meshing pair technology, applied in mechanical equipment, machines/engines, rotary piston machines, etc., can solve the problems of indexing error, short life, poor machining accuracy, etc., and achieve high efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

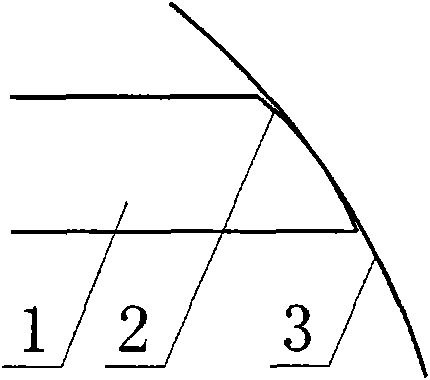

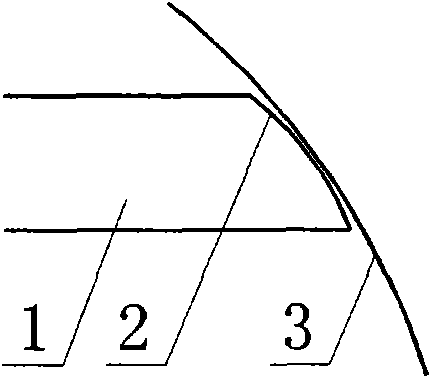

[0024] figure 1 It is the situation when the working tooth surface of the conventional star wheel meshes with the curved surface of the screw groove. Among them, 1 is the star wheel, 2 is the working tooth surface of the star wheel, and 3 is the working surface of the screw groove. The meshing gap between the star wheel working surface 2 and the screw groove working surface 3 is determined by the machining accuracy. When the processing accuracy is not enough, or the star wheel or the screw groove of the compressor is worn after working for a period of time, there will be a fixed meshing gap between the star wheel working surface 2 and the screw groove working surface 3, and this gap cannot be eliminated. of (see figure 2 ).

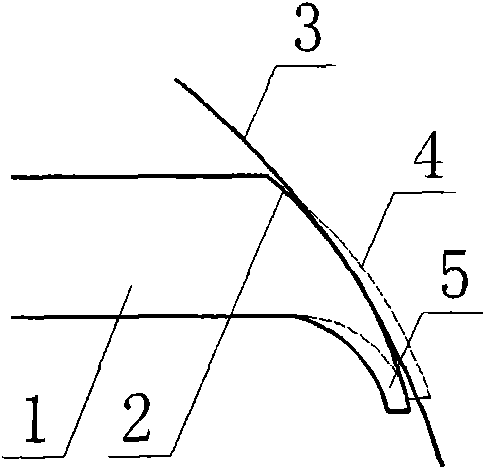

[0025] image 3 and Figure 4 It shows the structural form of the flexible meshing pair proposed by the present invention, and its main feature is that there is a flange 5 with gradually changing thickness on each working tooth surface of the star w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com