A brake cylinder of a rail vehicle hydraulic brake device

A technology for hydraulic braking and rail vehicles, applied in the direction of brake types, brake actuators, slack adjusters, etc., can solve the problems of many moving parts, hidden safety hazards, difficult processing and assembly, etc., and achieve less moving parts and high reliability High, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

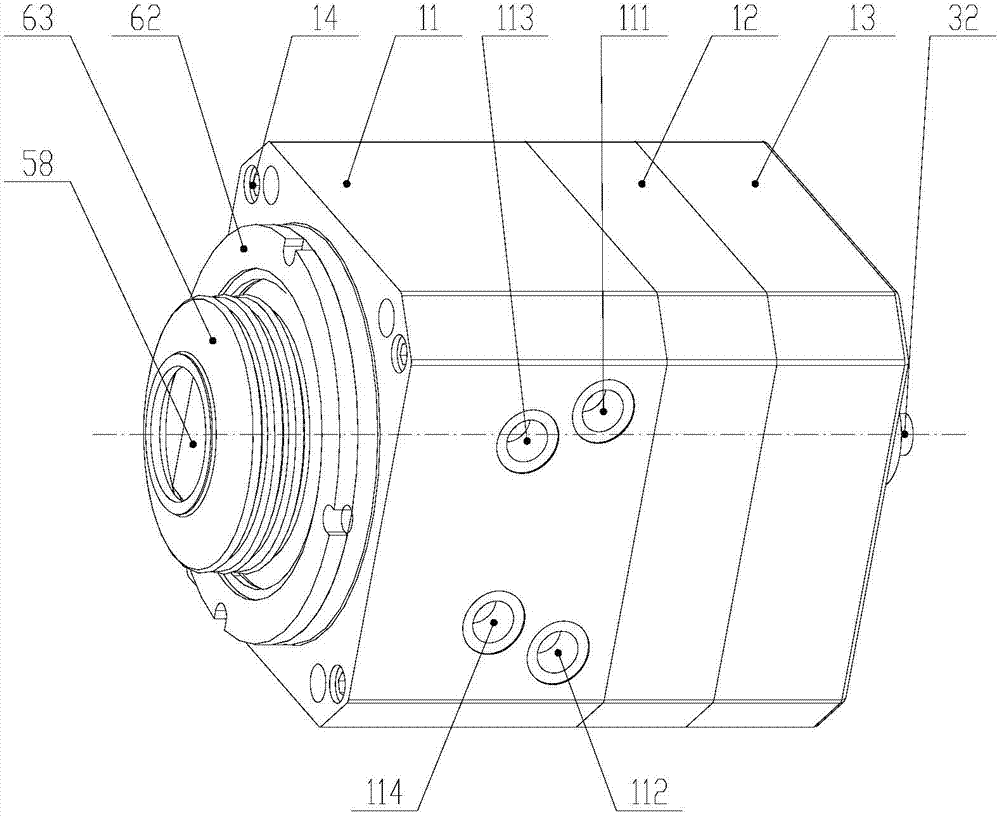

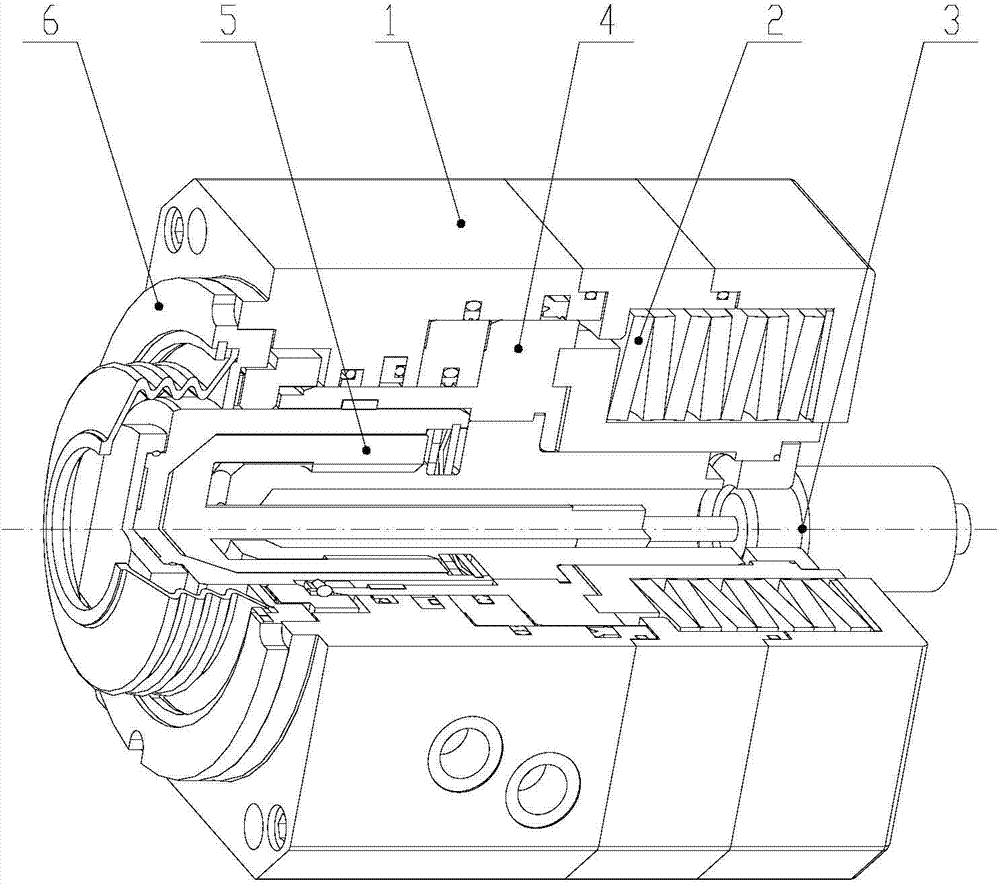

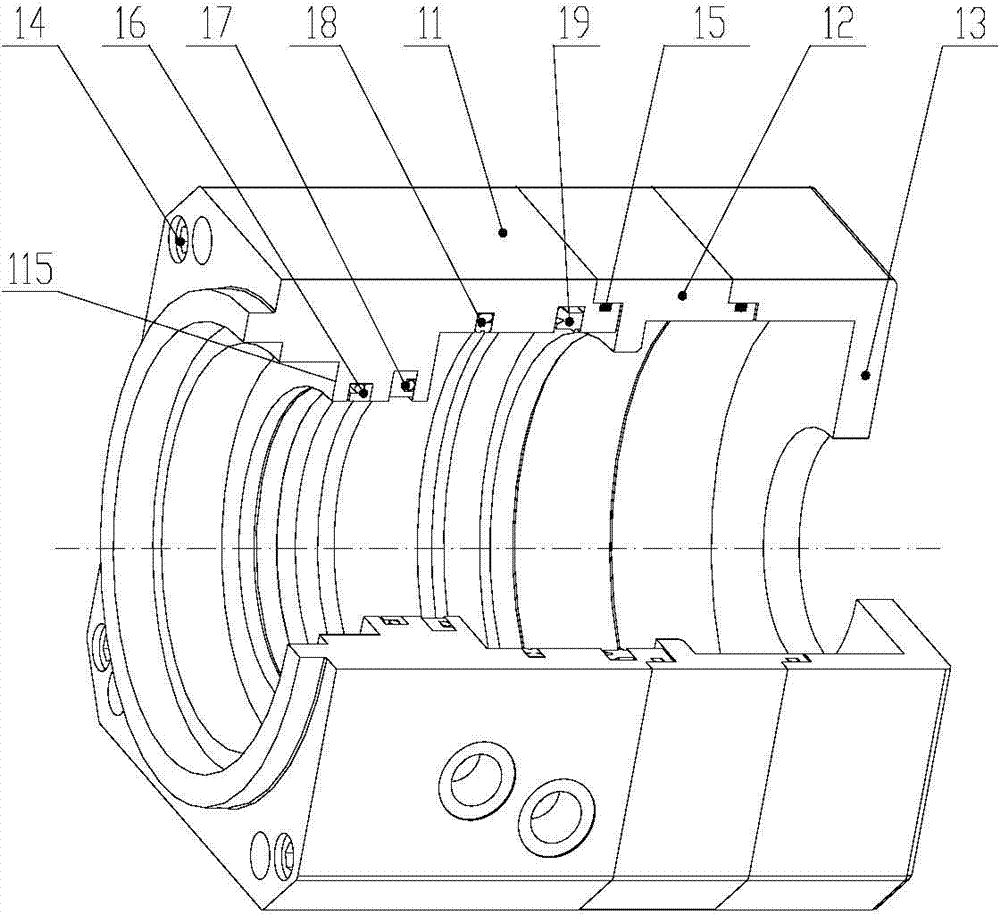

[0050] The present invention will be further described below in conjunction with the accompanying drawings. Such as Figure 1-15 As shown, a brake cylinder of a rail vehicle hydraulic brake device includes a housing member 1, a disc spring assembly 2, an indicator assembly 3, a piston assembly 4, a push rod assembly 5 and an end cover assembly 6, the push rod assembly 6 The rod assembly 5, the piston assembly 4, the disc spring assembly 2, and the indicator assembly 3 are sequentially installed in the cylindrical hole with steps inside the housing member 1 from front to rear and are the same as the main axis of the housing member 1, and the end cover assembly 6 Installed on the cylindrical step of the front end of the housing member 1 and the axis is the same as the main axis of the housing member 1;

[0051] The housing member 1 is cylindrical in shape with an outer side and an inner circle, and is connected from front to back by four screws 14 whose length is less than the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com