EPS special-shape package mold without vapor lock

A special-shaped and steam-plug technology, applied in the field of steam-plug-free EPS special-shaped packaging molds, can solve the problems of unevenness, smoothness that cannot meet customer requirements, and high water content in products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

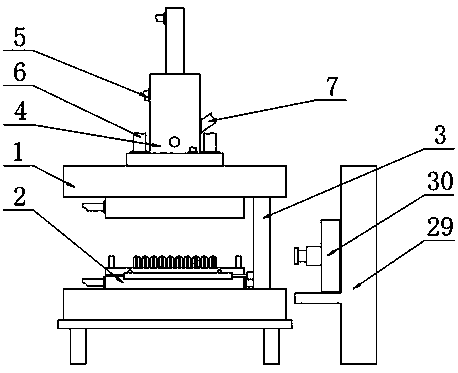

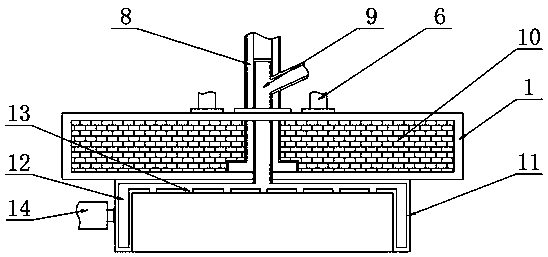

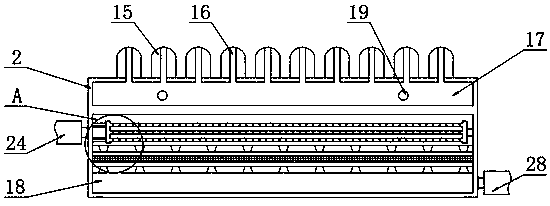

[0025] The present invention provides such as Figure 1-4 A steam plug-free EPS special-shaped packaging mold shown includes an upper mold 1 and a lower mold 2, a hydraulic rod 3 is provided between the upper mold 1 and the lower mold 2, and a material gun 4 is provided on the top of the upper mold 1. The surface of the material gun 4 is provided with a water outlet 5, both sides of the material gun 4 are provided with a steam interface 6, the side of the material gun 4 is provided with a vent 7, and the inside of the material gun 4 is provided with a water passage 8, The inside of the water channel 8 is provided with an air channel 9, the inside of the upper mold 1 is provided with a grid 10, the bottom surface of the upper mold 1 is provided with a frame 11, and the inside of the frame 11 is provided with a ventilation groove 12, so The inner wall of the card frame 11 is provided with an air outlet 13, and one side of the card frame 11 is provided with an air outlet pipe 14;...

Embodiment 2

[0030] The card frame 11 is fixedly connected with the upper mold 1, the number of the water outlets 5 is set to four, the water outlets 5 are communicated with the water passage 8, and the air outlet 7 is communicated with the air passage 9, so as to avoid passing through the air outlet. The incoming air contacts the moisture inside the water channel 8 .

[0031] The bottom surface of the water passage 8 is provided with holes, and the holes communicate with the inside of the upper mold 1. When the high-temperature steam touches the grid 10, the steam quickly dissipates heat and liquefies into water droplets that condense on the surface of the grid 10, and then Enter the inside of the water channel 8 through the holes on the surface of the water channel 8 , and then discharge the water and steam through the water outlet 5 on the surface of the water channel 8 , and the steam interface 6 communicates with the inside of the upper mold 1 .

[0032] The air outlet pipe 14 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com