Curing agent composition and coating composition comprising the same

A curing agent and composition technology, applied in epoxy resin coatings, coatings, etc., can solve problems such as damage to the appearance of the coating film, bonding defects, etc., and achieve the effect of excellent water resistance and fast curing speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

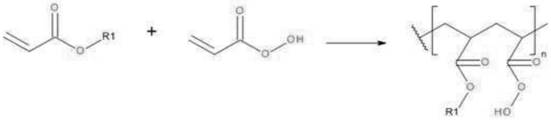

Method used

Image

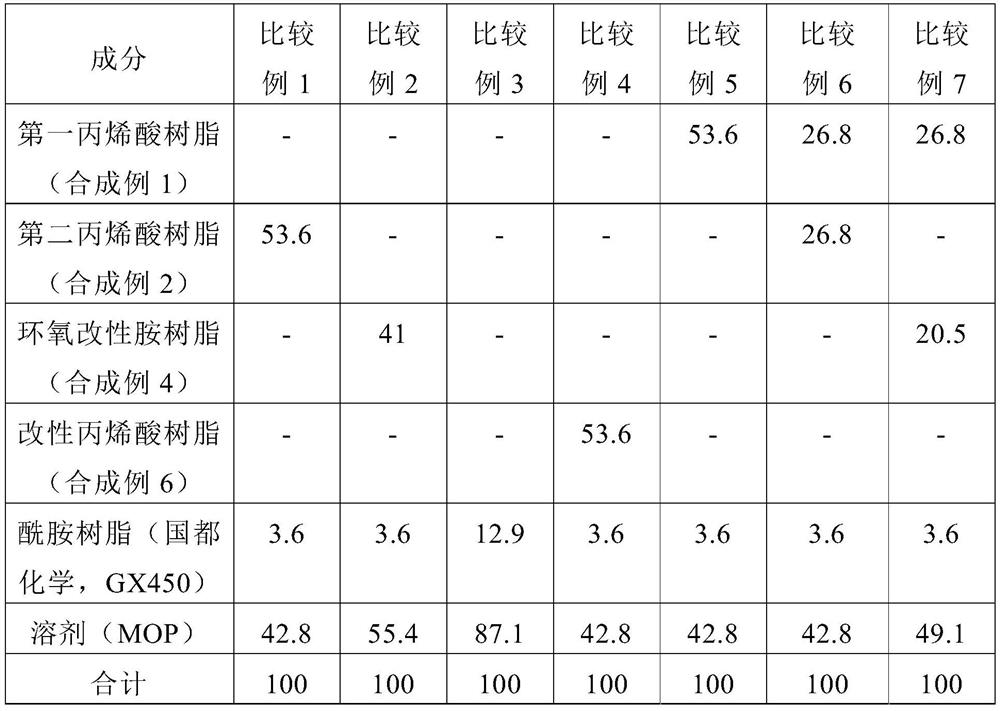

Examples

Synthetic example 1

[0073] After throwing 19 g of butanol into a synthesis four-necked flask equipped with a thermometer and a stirring device, the temperature was raised to 125° C. as a reflux temperature under a nitrogen atmosphere. Then 27.7 g of styrene, 18 g of butyl acrylate, 3.6 g of methacrylic acid, 6.7 g of dimethylaminoethyl methacrylate and 14 g of 2-ethylhexyl methacrylate were added and mixed, 1 g of benzoyl peroxide and 10 g of butanol were uniformly separated and dropped over 4 hours. After the dropwise addition was completed, polymerization was carried out at reflux temperature for 2 hours, thereby obtaining a solid content of 70% based on weight, a viscosity of Z3-Z6, an acid value of 34 mgKOH / g, and an amine value of 34 mgKOH / g 1. The first acrylic resin having a glass transition temperature of 15°C.

Synthetic example 2

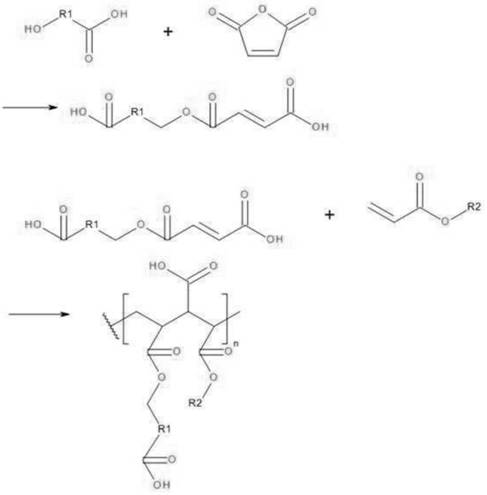

[0075] 1) Synthesis of intermediate reactants

[0076] After injecting 21 g of maleic acid, 49 g of hydroxystearic acid, and 30 g of butyl acetate into a synthesis four-necked flask equipped with a thermometer and a stirring device, reaction was performed at a temperature of 80° C. for 6 hours. Thereafter, cooling was carried out after the reaction until the acid value reached 271 mgKOH / g, thereby obtaining an intermediate reactant (resin) having a solid content of 70% by weight, a viscosity of V-Z, and an acid value of 271.2 mgKOH / g.

[0077] 2) Synthesis of the second acrylic resin

[0078] After throwing 16 g of butanol into a synthesis four-necked flask equipped with a thermometer and a stirring device, the temperature was raised to 125° C. as a reflux temperature under a nitrogen atmosphere. Then add and mix 26g of styrene, 14g of butyl acrylate, 12.5g of intermediate reactant (Long chain acid), 14g of 2-ethylhexyl methacrylate and 7g of dimethylammonium methacrylate Et...

Synthetic example 3

[0080] 1) Synthesis of intermediate reactants

[0081] After injecting 21 g of maleic acid, 25 g of hydroxymethylbenzoic acid, and 19.7 g of butyl acetate into a synthesis four-necked flask equipped with a thermometer and a stirring device, the reaction was performed at a temperature of 80° C. for 6 hours. Thereafter, cooling was carried out after the reaction until the acid value reached 271 mgKOH / g, thereby obtaining an intermediate reactant (resin) having a solid content of 70% by weight, a viscosity of V-Z, and an acid value of 271.2 mgKOH / g.

[0082] 2) Synthesis of the second acrylic resin

[0083] After throwing 16 g of butanol into a synthesis four-necked flask equipped with a thermometer and a stirring device, the temperature was raised to 125° C. as a reflux temperature under a nitrogen atmosphere. Then add and mix 26 g of styrene, 14 g of butyl acrylate, 12.5 g of intermediate reactants, 14 g of 2-ethylhexyl methacrylate, and 7 g of dimethylaminoethyl methacrylate ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| amine value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com