Modular TBM cutter disc capable of performing variable diameter expanding excavation

A modular, cutterhead technology for mining equipment, earthmoving, tunneling, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings.

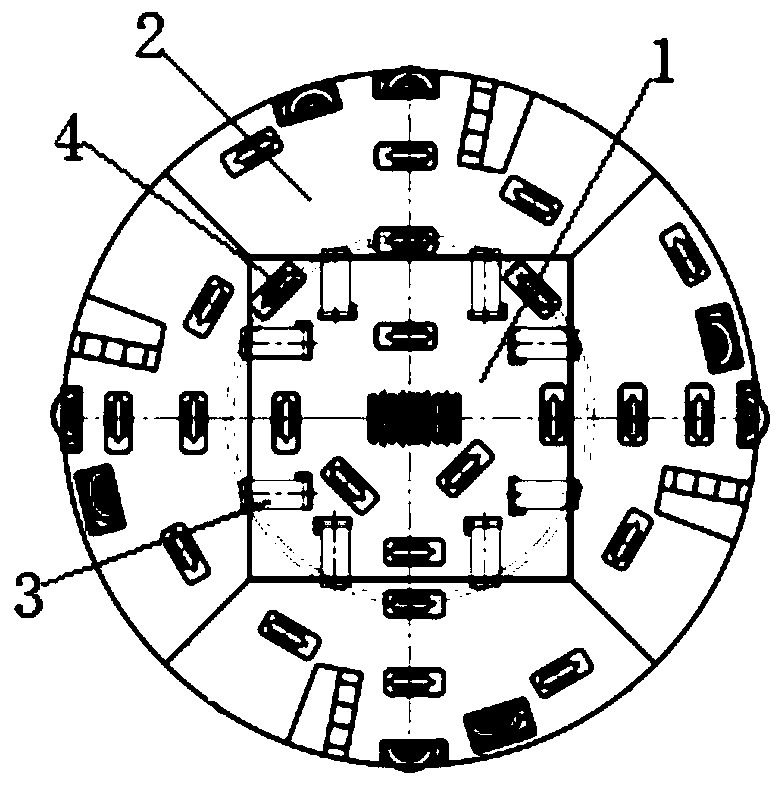

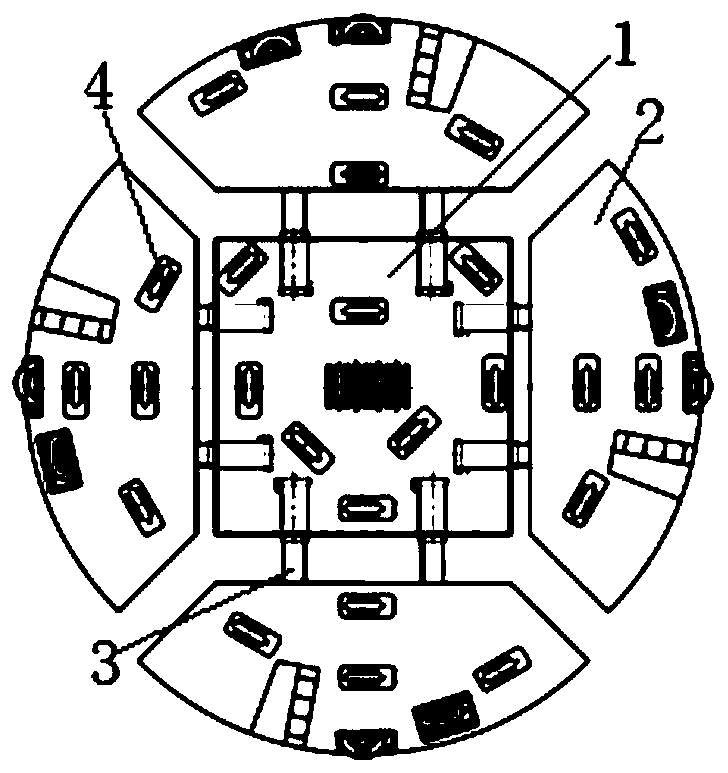

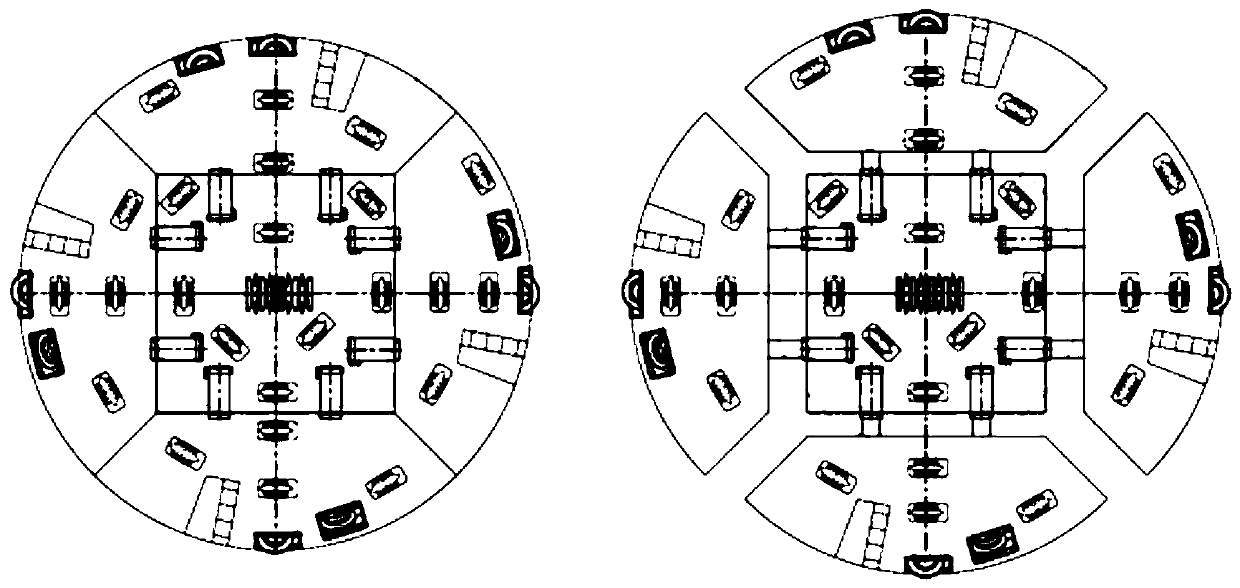

[0015] See attached figure 1 to attach image 3 The preferred embodiment of the invention is described in detail. A modularized variable-diameter expanded TBM cutterhead includes a quadrilateral structure central cutterhead module 1 with a central gyrator installed, and four sides of the central cutterhead module 1 arranged around the A fan-shaped peripheral cutterhead module 2, four peripheral cutterhead modules 2 are respectively located on the four sides of the central cutterhead module 1, so as to form a circular cutterhead, the central cutterhead module 1 and the peripheral The cutterhead modules 2 are connected by two push cylinders 3, the base of the push cylinder 3 is fixedly installed on the central cutterhead module 1, and the piston rod head of the push cylinder 3 is fixedly installed on the peripheral cutterhead module 2, And the jacking cylinder 3 is pos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com