Air inlet duct adjusting device and method

A technology of air inlet and sliding device, which is applied in the direction of jet propulsion device, gas turbine device, ramjet engine, etc., can solve the problem that the air inlet cannot be adjusted, achieve stable ending shock wave system, improve anti-backpressure ability, The effect of strong engineering realization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Embodiment 1: An adjustable device for an air inlet, including an air inlet main body, a slider, a driving mechanism and a locking mechanism. There is a groove on the inner surface of the airway, and the slider is connected to the groove. The power provided by the driving mechanism slides along the groove. When the slide reaches a suitable position, the locking mechanism locks the slider. When the aircraft is flying at a speed greater than Mach 3.5, that is, at a high Mach number, the slider is fixed at the throat, and when the aircraft is flying at a speed of less than Mach 3.5, that is, at a low Mach number, the slider moves to the rear of the throat and is fixed.

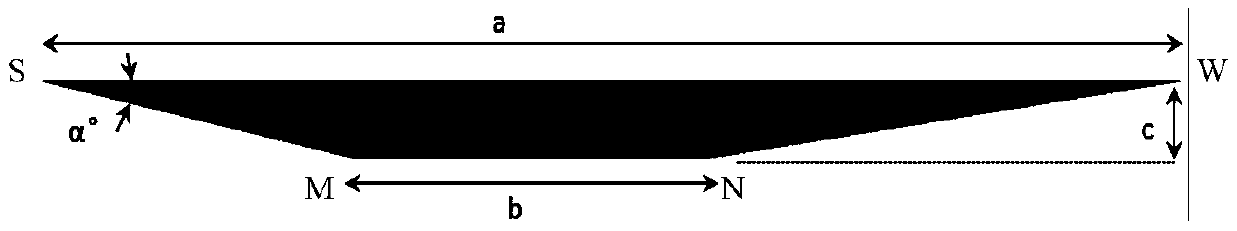

[0025] The cross-sectional shape of the slider is as figure 1 It is shown as a quadrilateral, and its height is not greater than the difference between the maximum height at the rear of the inlet throat and the height at the throat, and the length of the slider in the axial direction of the projectile body...

Embodiment 2

[0028] Embodiment 2: An adjustable device for an air inlet, including an air inlet main body, a slider, a driving mechanism and a locking mechanism. There is a groove on the inner surface of the airway, and the slider is connected to the groove. The power provided by the driving mechanism slides along the groove. When the slide reaches a suitable position, the locking mechanism locks the slider. When the aircraft is flying at a speed greater than Mach 3.5, that is, at a high Mach number, the slider is fixed at the throat, and when the aircraft is flying at a speed of less than Mach 3.5, that is, at a low Mach number, the slider moves to the rear of the throat and is fixed.

[0029] The cross-sectional shape of the slider is as figure 1 As shown, its height is equal to the difference between the maximum height of the rear portion of the throat of the air inlet and the height of the throat, and the length is 2.2 times of the height. On its upper surface, there is a device that m...

Embodiment 3

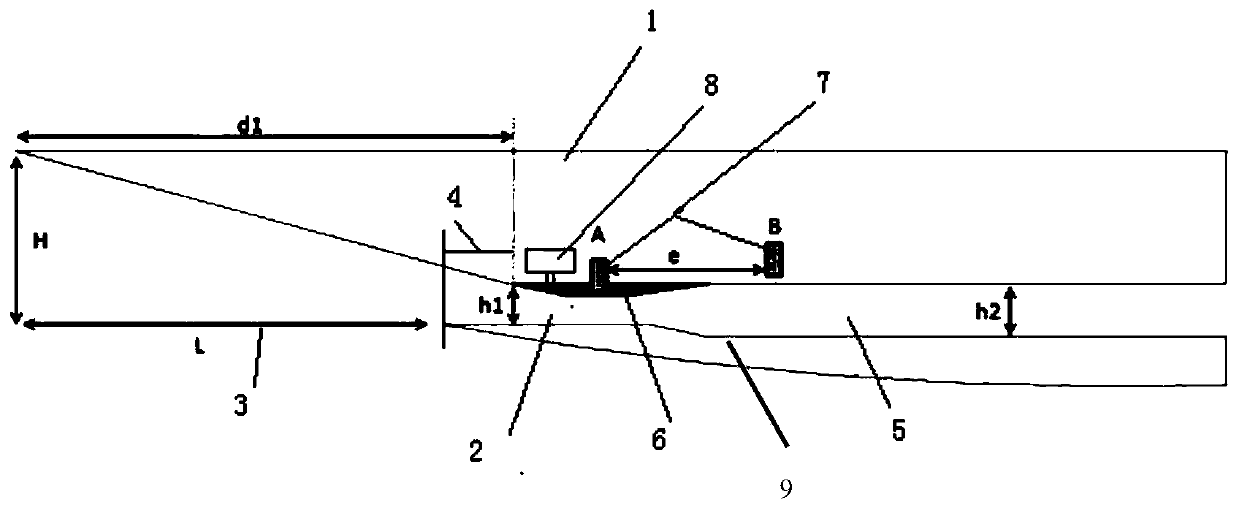

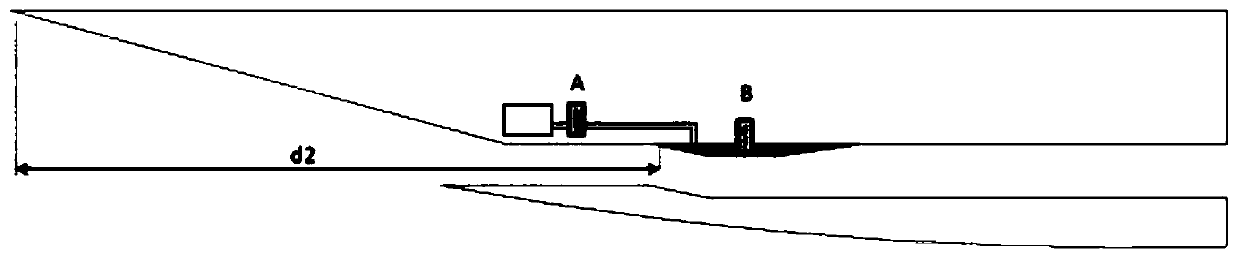

[0031] Embodiment 3. An adjustable air inlet device, in which the locking device is installed on the projectile and is a positioning pin, and two or more can be provided as required. figure 2 is the state of the air inlet when the aircraft is flying at a high Mach number. At this time, the slider is at the throat of the air inlet, and the locking mechanism A locks the slider. image 3 Shown is the state of the air inlet when the aircraft is flying at a low Mach number. At this time, the slider is behind the throat of the air inlet, and the locking mechanism B locks the slider. All the other devices are the same as in Example 1.

[0032] The device can be used in any form of air intake, figure 2 , 3 For this purpose, the device is set in the state of the lower jaw inlet. In the dual inlet, the slider can be located on the side of the outer cover or on the side of the side plate; in the center cone inlet, the slider can be located on the side of the compression cone. .

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com