An adjustable flow device simulating the nozzle of an aeroengine

An aero-engine and adjustable technology, which is applied in the direction of machine/engine, jet propulsion device, jet engine test, etc., can solve the problem that the dynamic performance of butterfly valve aerodynamic flow field is greatly affected, the control logic of multi-flap valve is complicated, and the valve body of sleeve valve Complicated structure and other problems, to achieve the effect of reducing the risk of motion sticking, good quality of flow field, and good quality of intake and exhaust airflow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

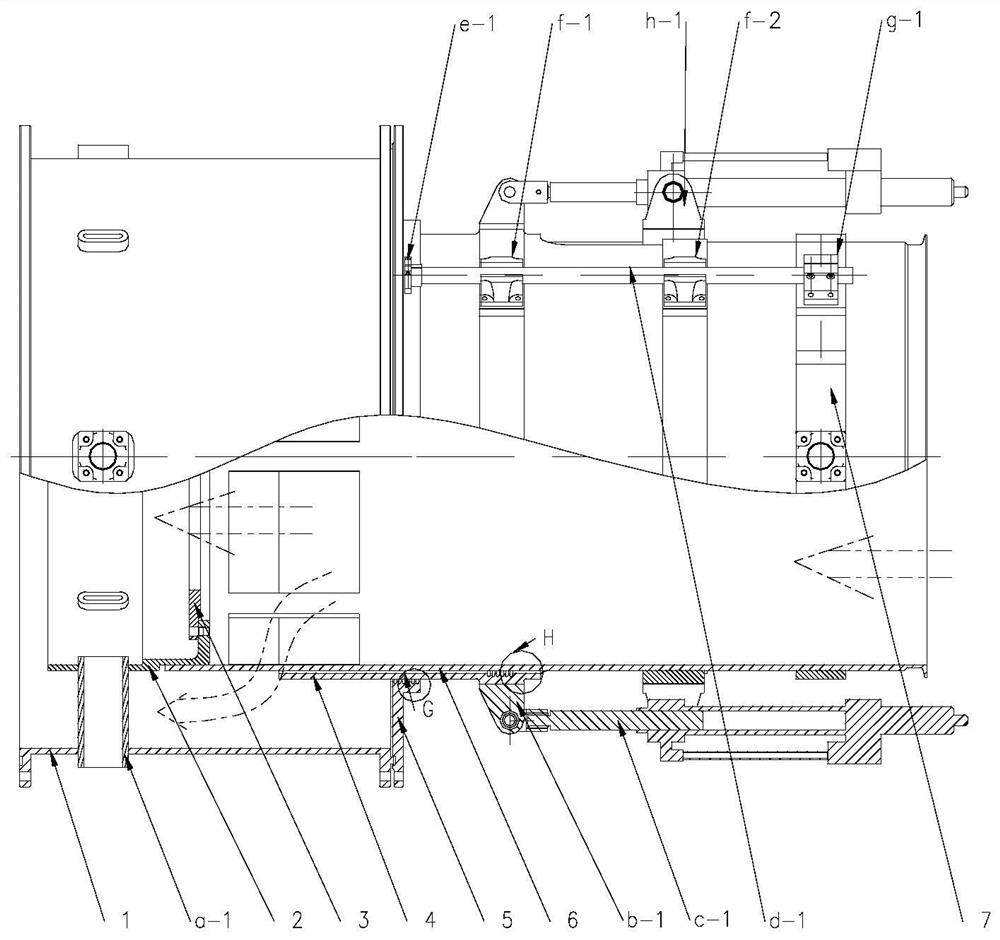

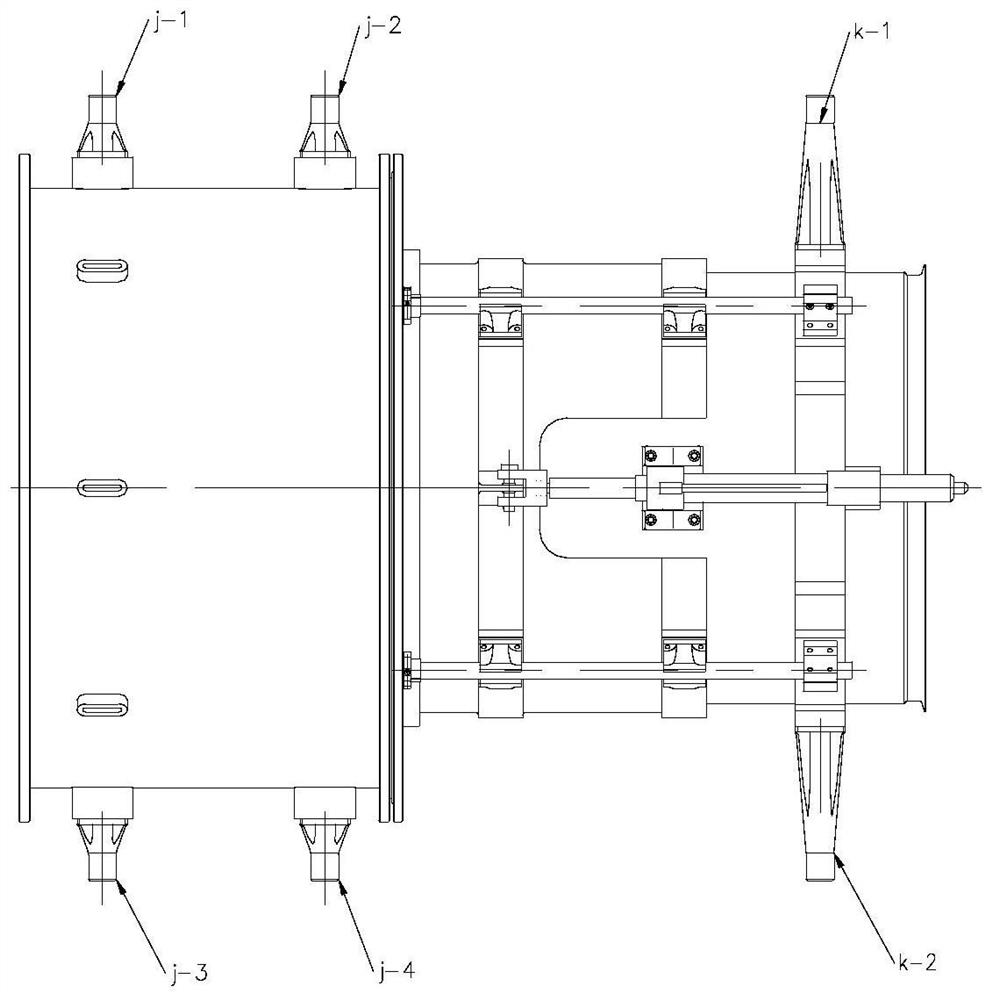

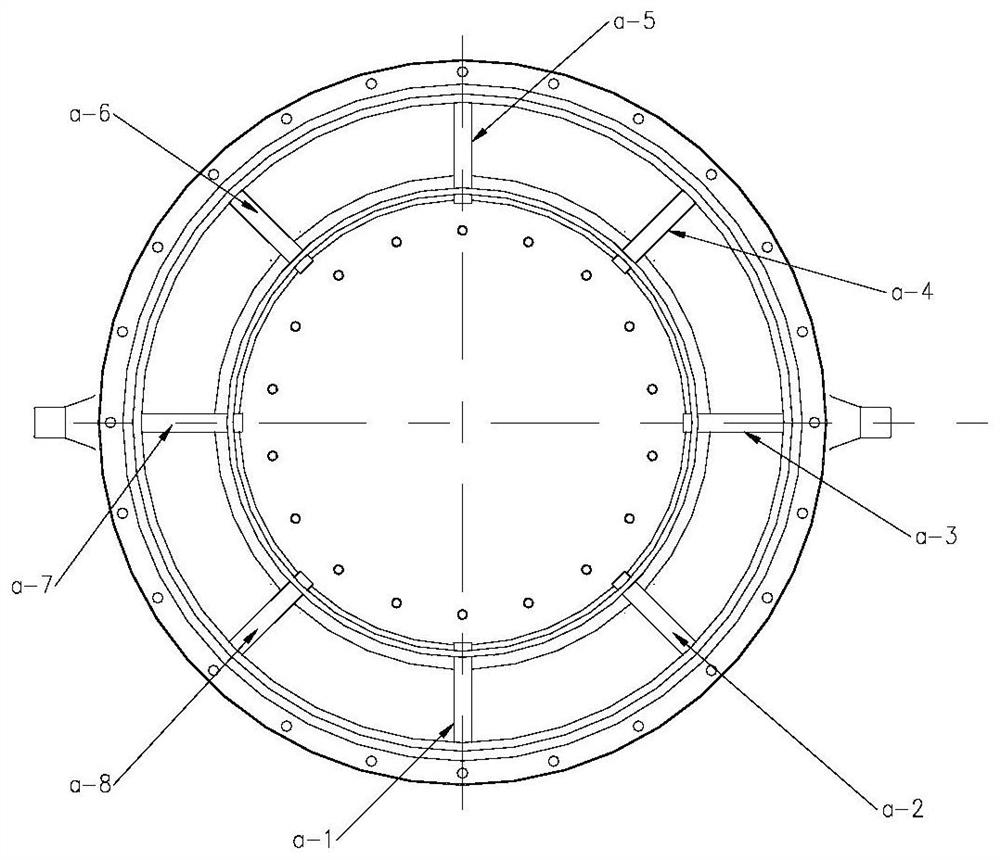

[0027] The following will refer to the attached Figure 1-5 Describe in detail the adjustable flow device simulating an aeroengine nozzle of the present invention. The adjustable flow device of the present invention comprises a nozzle outer tube 1, a nozzle inner tube 2, a normally open through hole 3, a movable sleeve 4, a sealing head 5, a straight nozzle tube 6, a straight outer fixed ring 7, a fixed cascade 1, a One sleeve lower lug seat b-1, the first lower drive cylinder c-1, the first guide rail d-1, the first head guide rail seat e-1, the sleeve guide rail bearing seat 1, the second sleeve guide rail bearing seat f-2, the first upper drive cylinder fixing seat h-1, the first straight guide rail fixing seat g-1, the trunnion j-1 installed on the first outer cylinder, the trunnion j-2 installed on the second outer cylinder, the third outer cylinder The barrel mounts a trunnion j-3, the fourth outer barrel mounts a trunnion j-4, the first straight barrel mounts a trunnio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com