Temperature liquid level monitoring device for liquid immersion power equipment

A technology for power equipment and liquid level monitoring, applied in measuring devices, instruments, etc., can solve problems such as inability to perform pre-intervention, unscientific, untimely, etc., to ensure the quality of power supply, intelligent asset management, and achieve the effect of asset management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

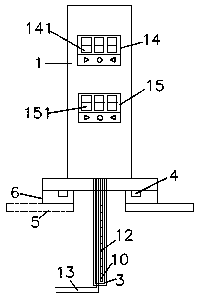

[0032] Embodiment one: if figure 1 As shown, a temperature and liquid level monitoring device for liquid immersion power equipment does not include a temperature data transmission device 11, a liquid level position data transmission device 16, a pressure release device 7, a float 8, a transparent tube 9 and an inspection window.

Embodiment 2

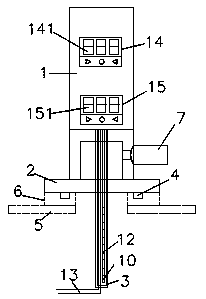

[0033] Embodiment two: if figure 2 As shown, a temperature and liquid level monitoring device for liquid immersion power equipment does not include a temperature data transmission device 11, a liquid level position data transmission device 16, a float 8, a transparent tube 9 and an inspection window.

Embodiment 3

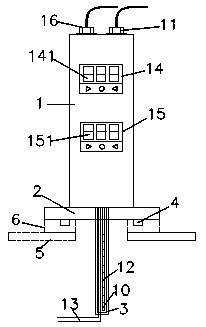

[0034] Embodiment three: as image 3 As shown, a temperature and liquid level monitoring device for liquid immersion power equipment does not include a pressure release device 7, a float 8, a transparent tube 9 and an inspection window.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com