Method for designing lower combination stiffness of iron base plate of elastic separation type fastener system

A design method and technology of iron backing plate, applied in design optimization/simulation, computer-aided design, calculation, etc., can solve the problem of inconsistent design stiffness of iron backing plate, and achieve the effect of accurate design results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

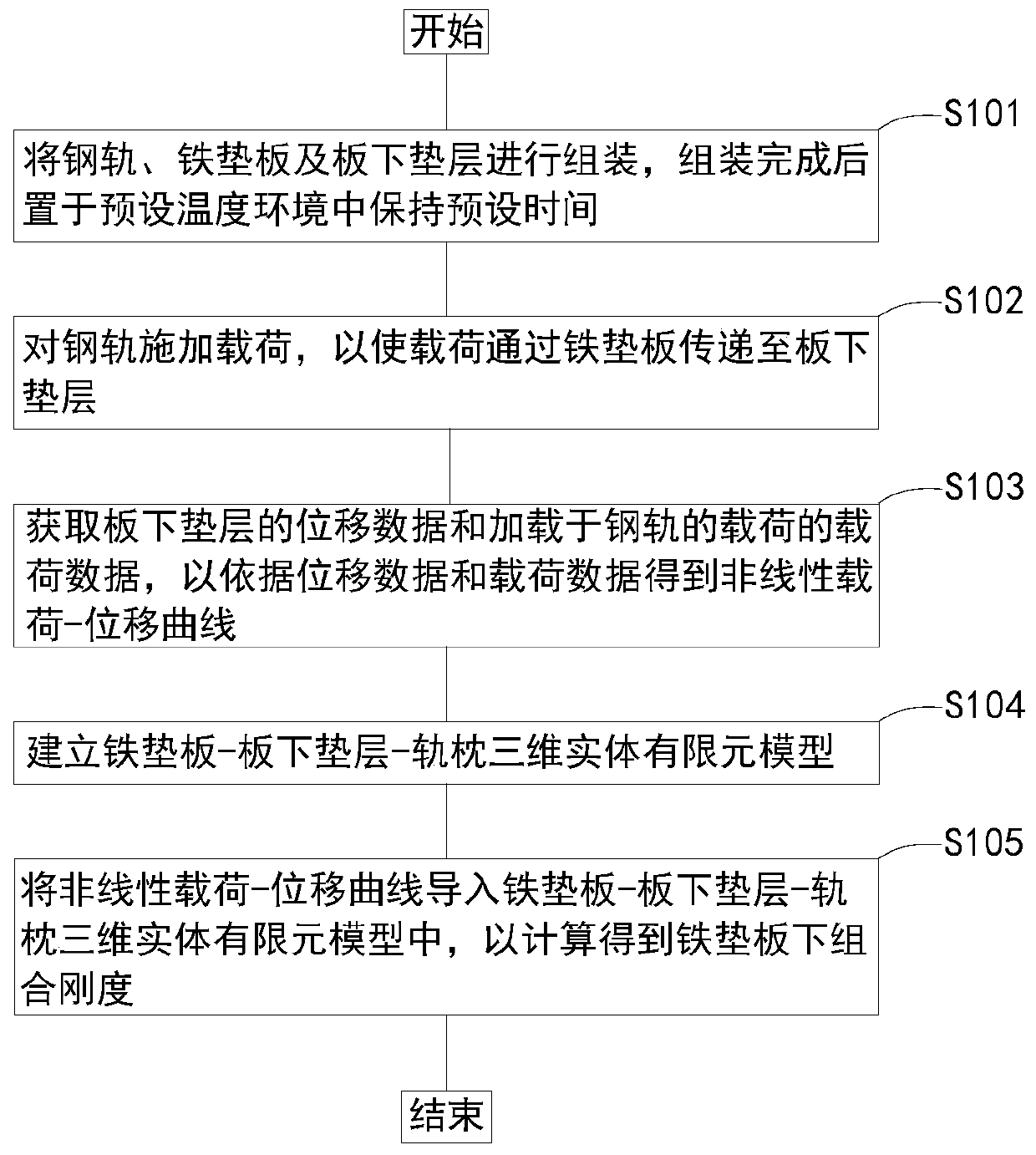

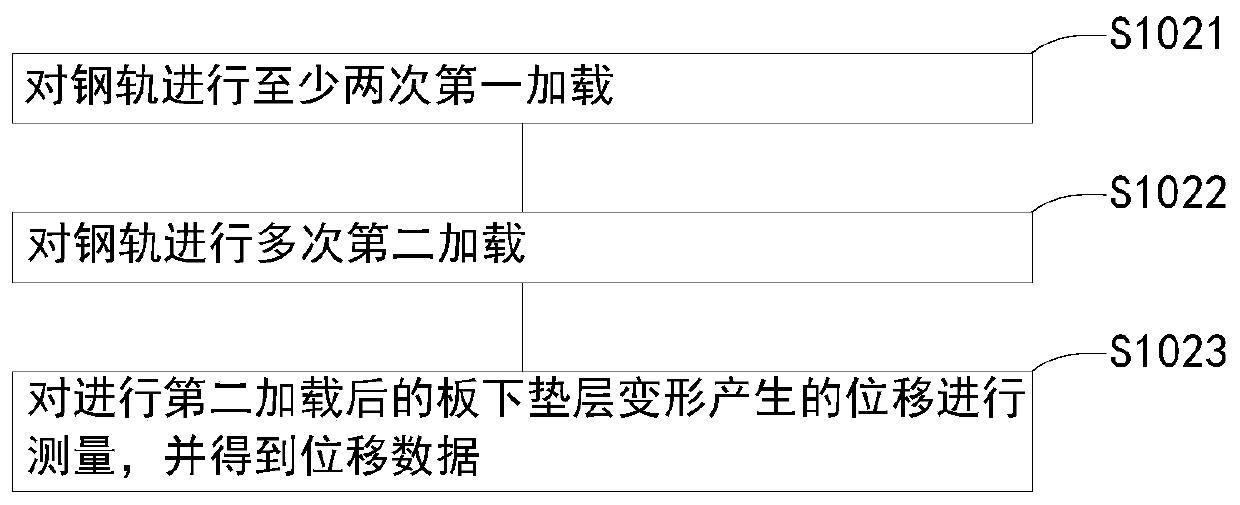

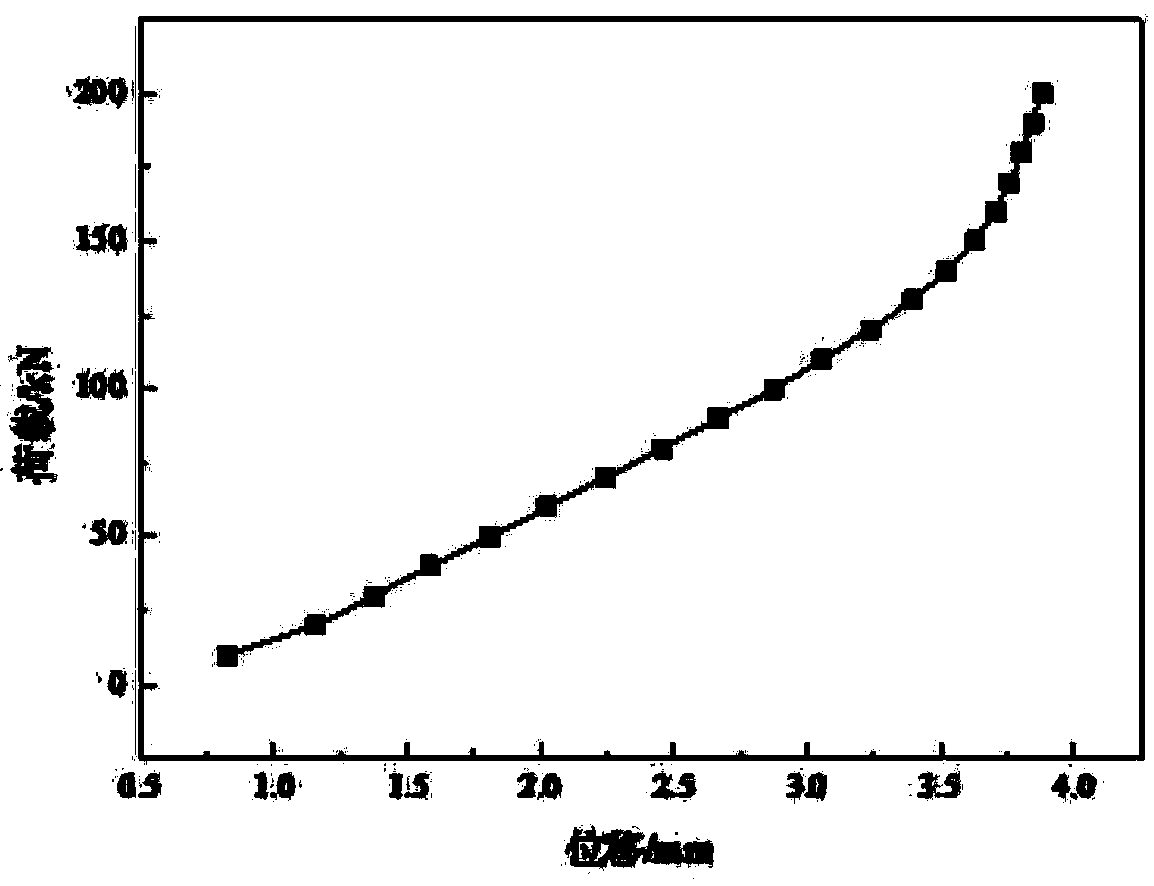

[0059] figure 1 For the schematic block diagram of the design method of the combined stiffness under the iron backing plate of an elastic split fastener system provided by the embodiment of the present invention, please refer to figure 1 , the design method of the combined stiffness under the iron backing plate of the elastic split fastener system includes:

[0060] S101, assembling the rails, the iron backing plate and the underlayment under the plate, and placing them in a preset temperature environment for a preset time after the assembly is completed.

[0061] The steel rail adopted in this embodiment is a 60kg / m short steel rail, and the iron backing plate adopts the DZIII type elastic split fastener system iron backing plate. The preset temperature is 23±3°C, and the preset time is 24 hours. The experimental assembly after constant temperature maintenance can avoid the influence of temperature on material deformation to a certain extent, making the design results more a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com