Patents

Literature

34results about How to "Accurate design results" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

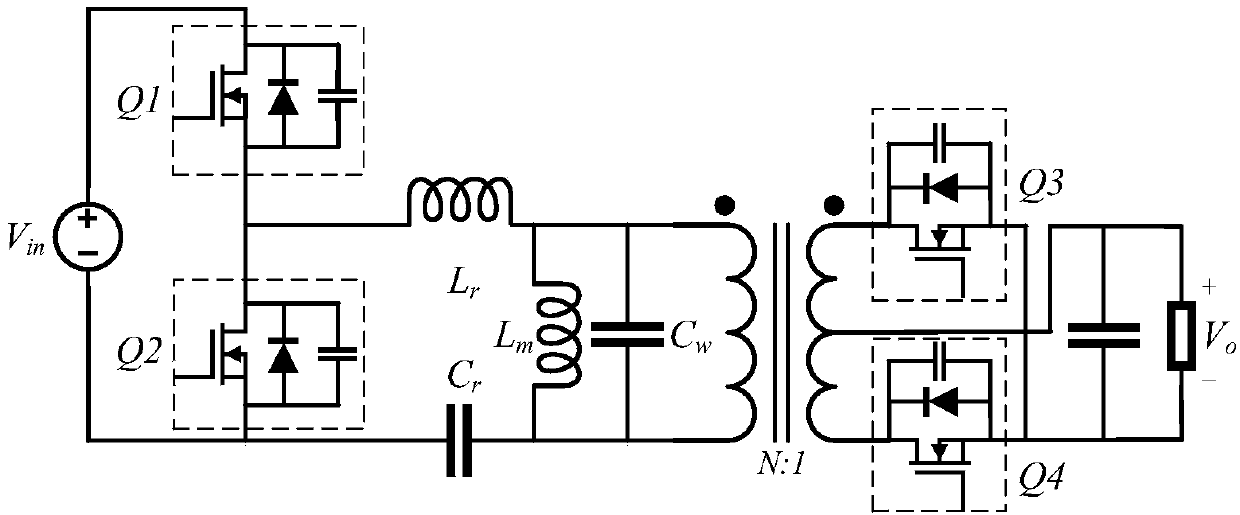

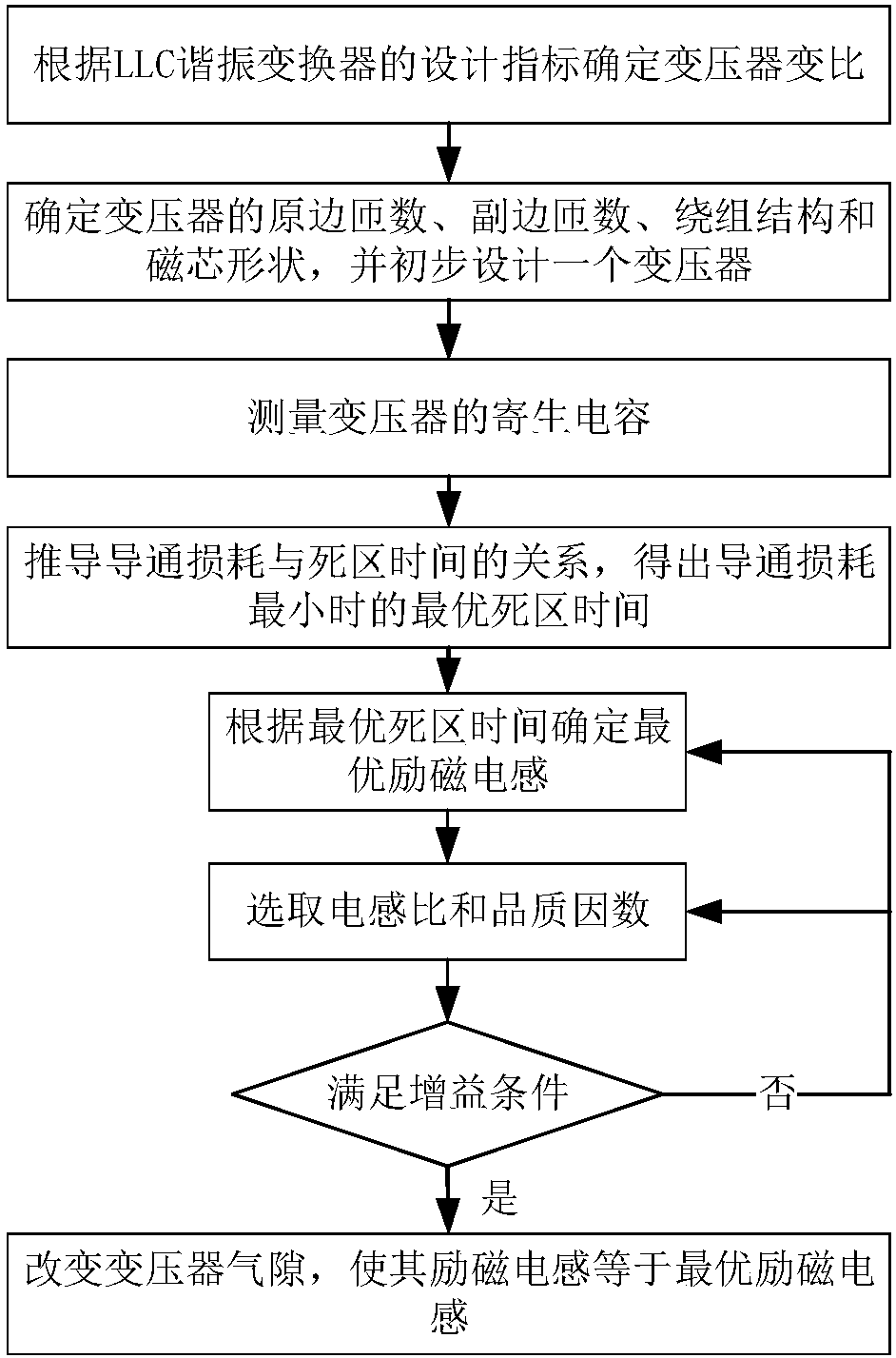

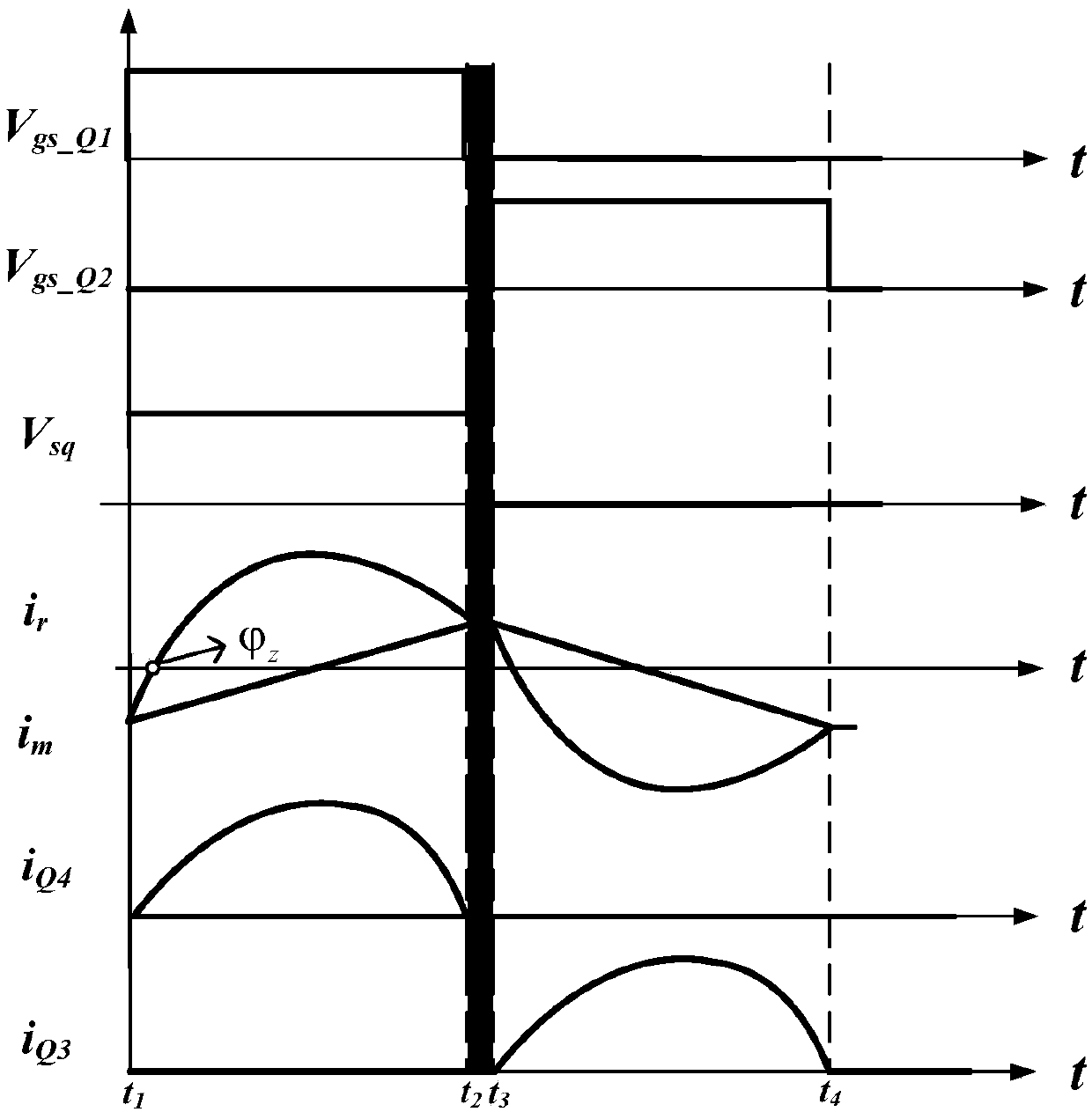

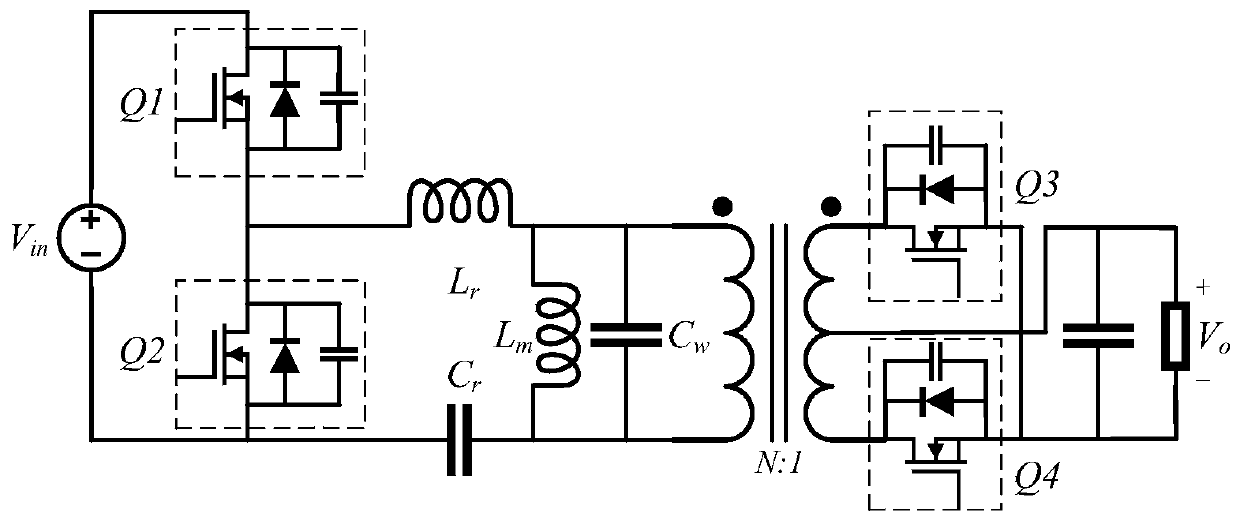

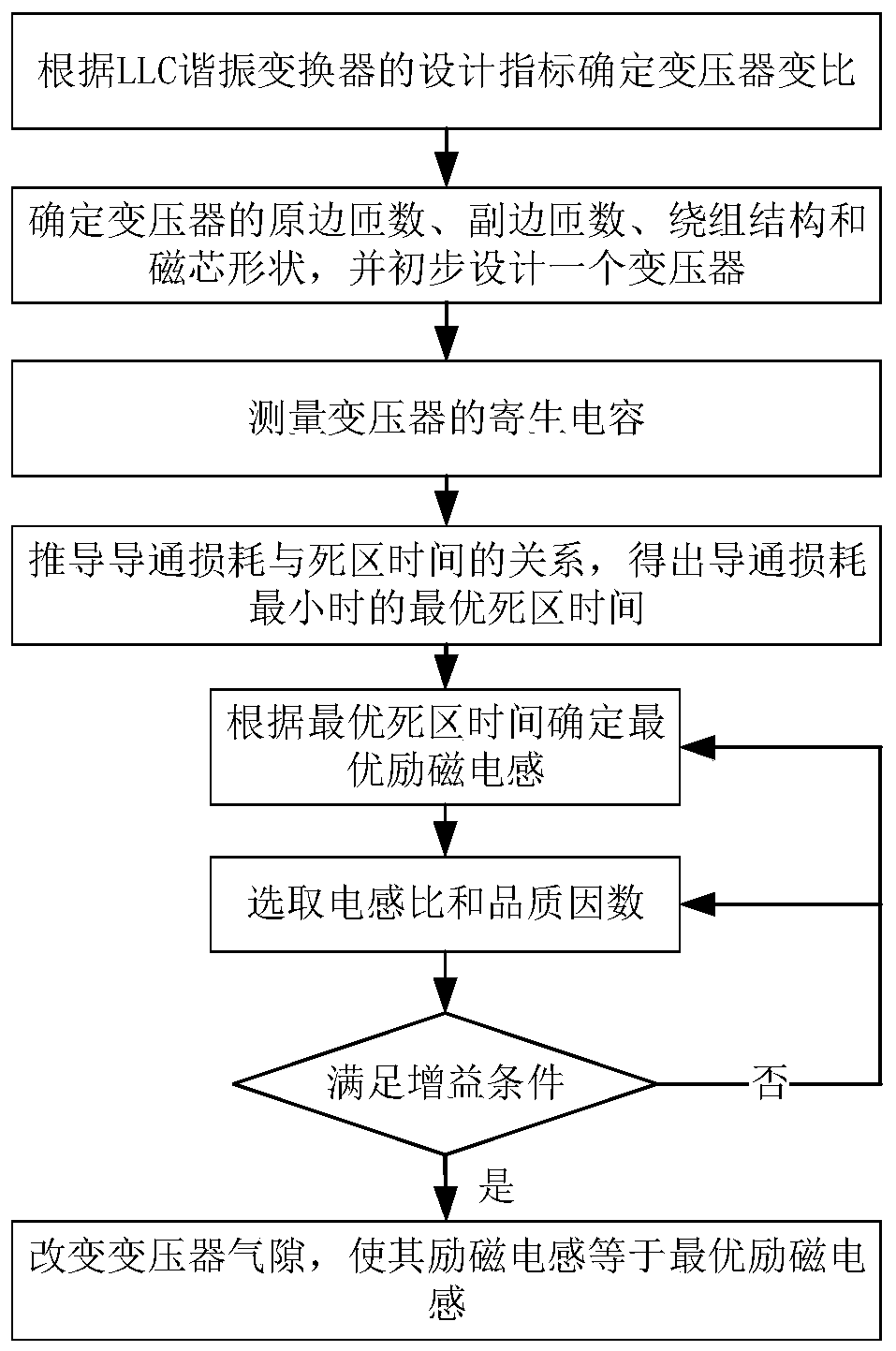

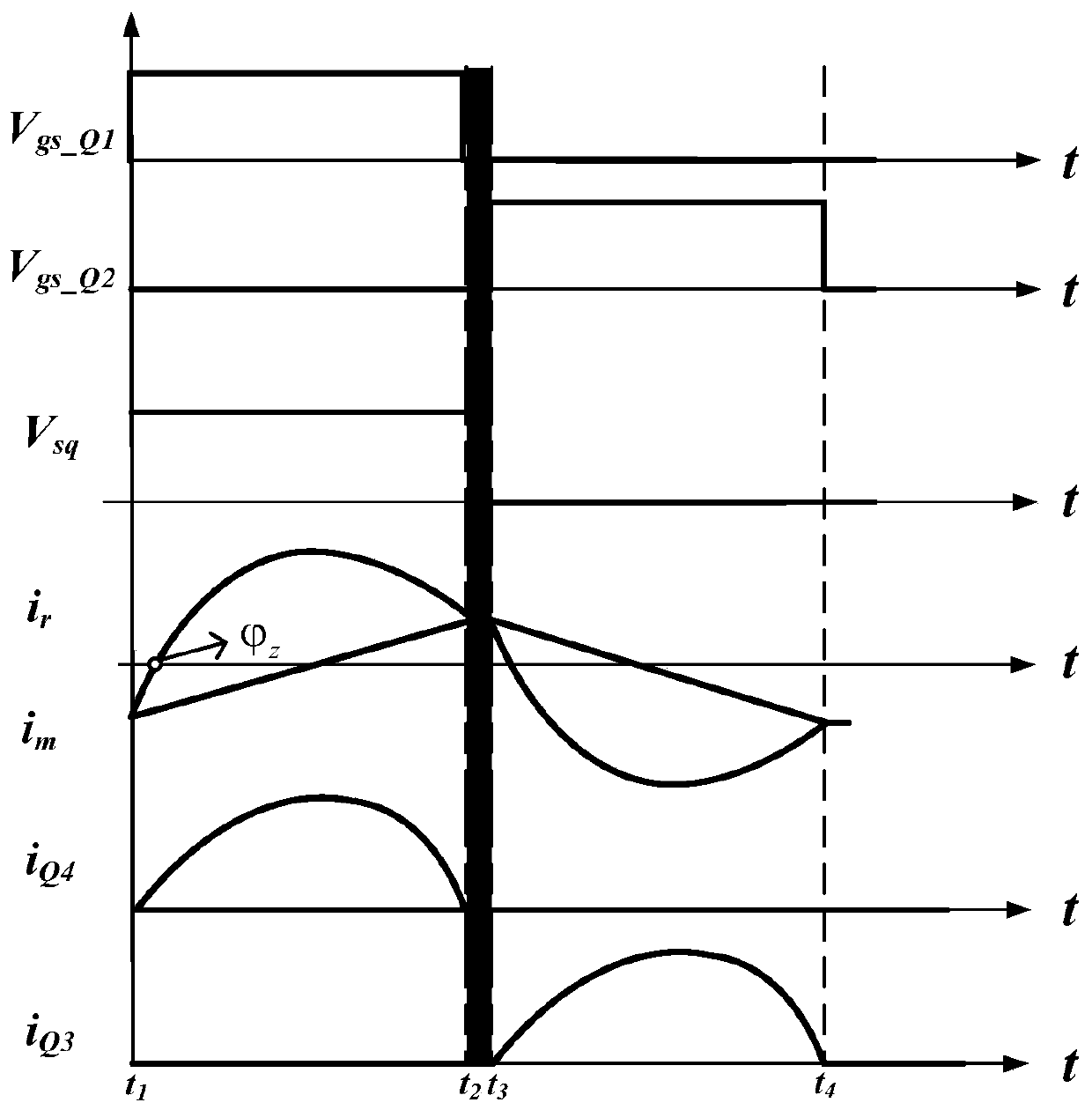

Optimal design method of LLC resonant converter

ActiveCN108631597AImprove efficiencyUniversalEfficient power electronics conversionDc-dc conversionResonanceParasitic capacitance

The invention discloses an optima design method of an LLC resonant converter. The method comprises the following steps: determining transformer ratio of transformation according to a design index of an LLC resonant converter; determining the primary side turns, the secondary side turns, a winding structure and a magnetic core shape of the transformer according to the ratio of transformation of thetransformer, and initially designing a transformer; measuring a parasitic capacitance of the transformer; deducing the relation formula of switch-on loss and dead time to obtain the optimal dead timewhen the switch-on loss is minimum; determining the optimal magnetic inductance according to the optimal dead time; selecting the inductance ratio and quality factor capable of satisfying a gain condition; and obtaining a resonance inductance value and a resonance capacitance value according to the optimal magnetic inductance, the inductance ratio and the resonance frequency; and changing the airgap of the transformer to enable the magnetic inductance to be equal to the optimal magnetic inductance. Through the method disclosed by the invention, the problem that the traditional LLC resonant converter design method depends too much on the experience and is inaccurate is solved, the design result is more accurate, and can be popularized to various application occasions.

Owner:XI AN JIAOTONG UNIV

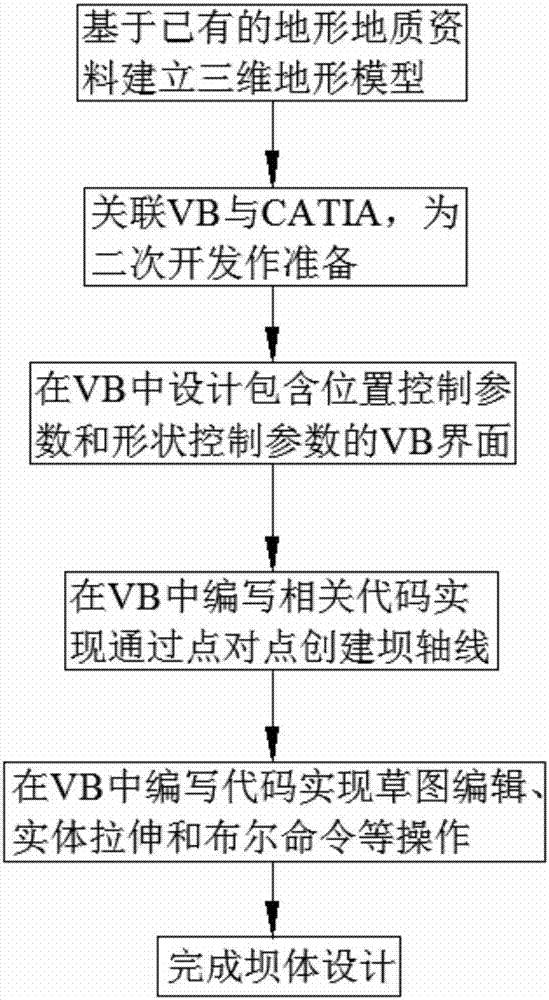

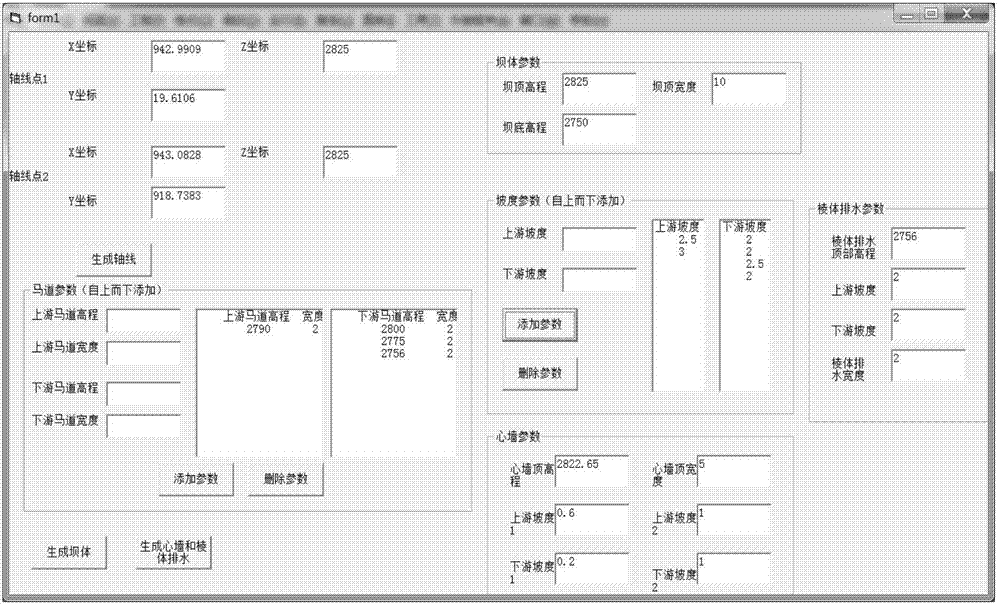

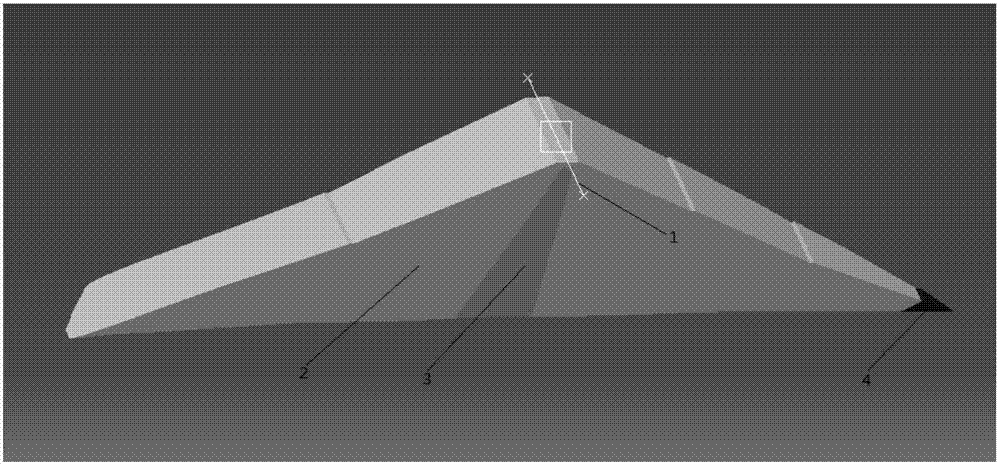

Modeling method for inclined core wall earth-rockfill dam based on VB and CATIA

InactiveCN106874610AChange the problem of insufficient intuitionSolve duplication of workGeometric CADDesign optimisation/simulationTerrainInformatization

The invention discloses an informatization modeling method for an earth-rockfill dam based on VB and CATIA. Secondary development is carried out on the basis of the VB language and the CATIA, the VB calls the CATIA, and modeling is carried out. The modeling method comprises the following steps of establishing a three-dimensional terrain model on the basis of existing topographic and geological data; linking the VB with the CATIA; designing a VB interface comprising location control parameters and shape control parameters in the VB; writing codes in the VB and creating a dam axis according to endpoint coordinates of the ends of the dam axis; writing codes in the VB and completing design of a dam body; running a program, inputting the parameters, and generating a model. A traditional design mode is abstract in expression and poor in error-correcting capability, and greatly limits improvement of design efficiency. According to the informatization modeling method based on the VB and the CATIA, the characteristics of secondary development, parameterization and three-dimensional visualization of software are utilized, the disadvantage of the traditional water conservancy project design mode can be avoided, and the efficiency is improved.

Owner:HOHAI UNIV

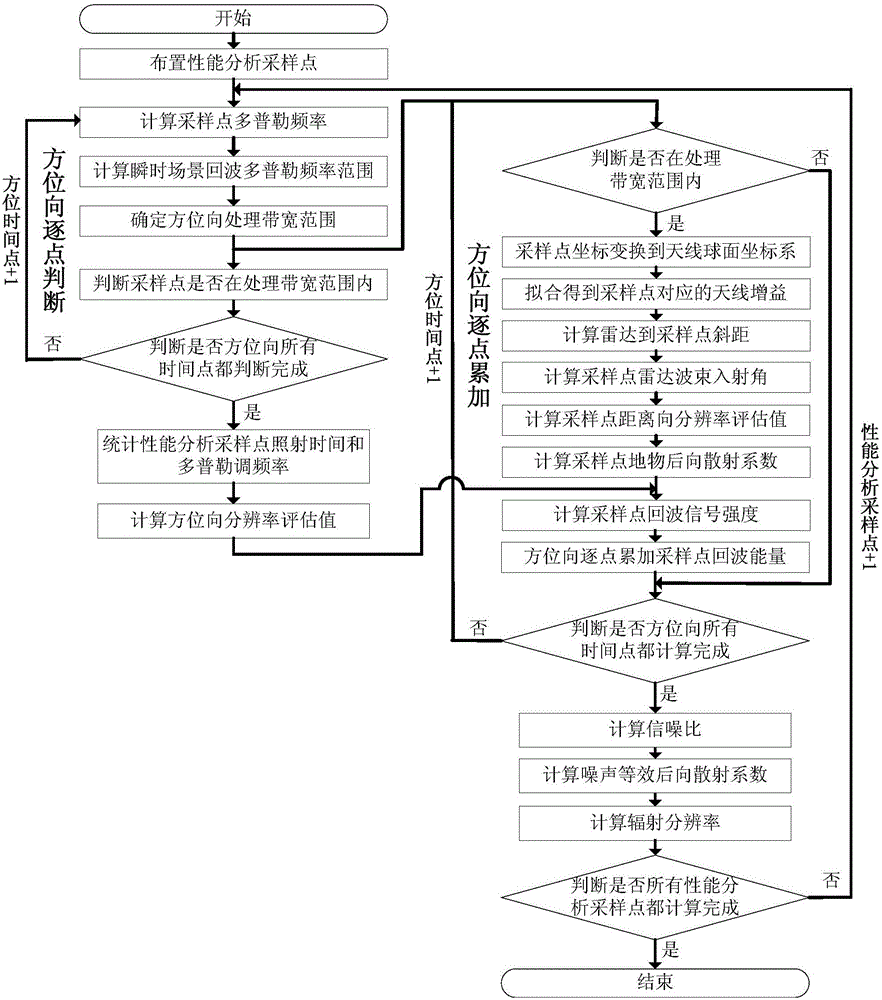

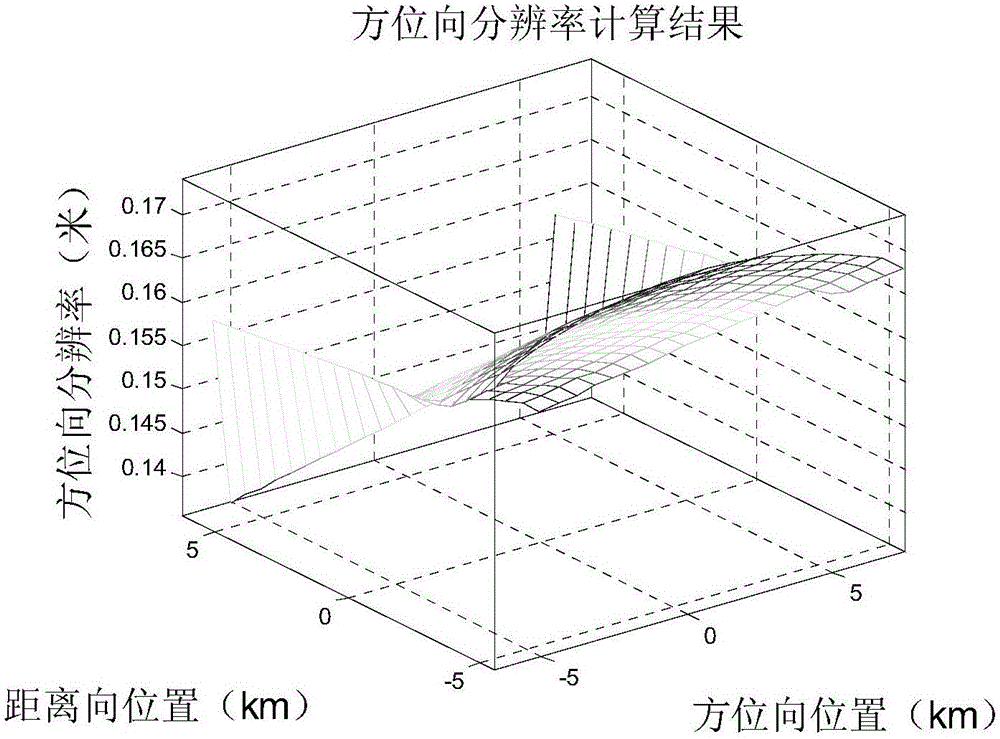

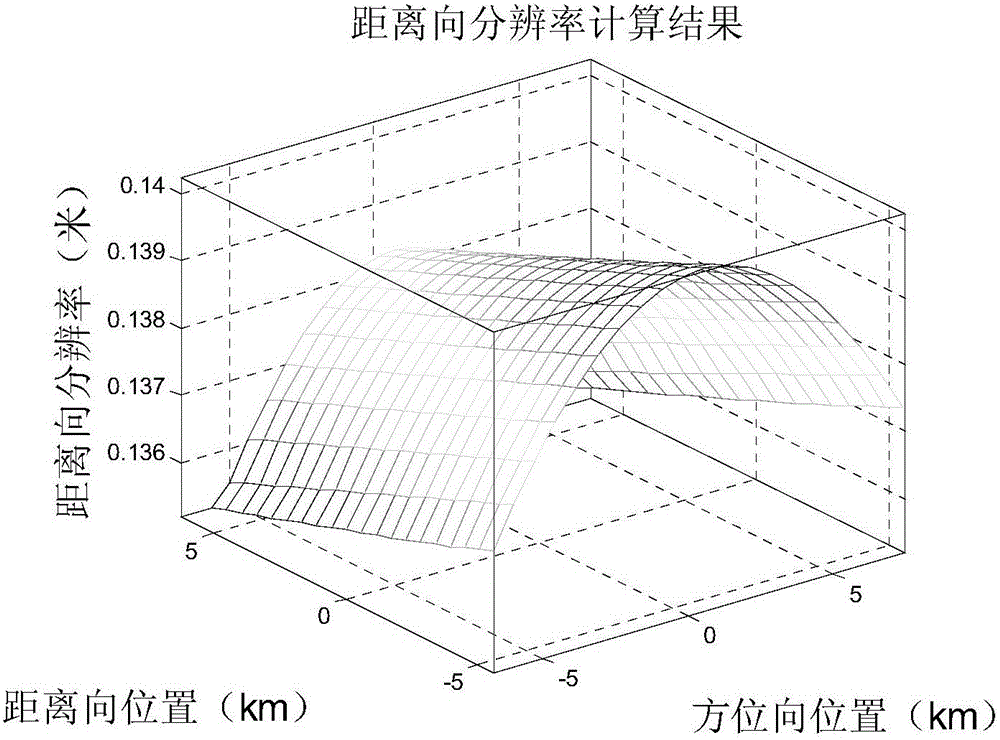

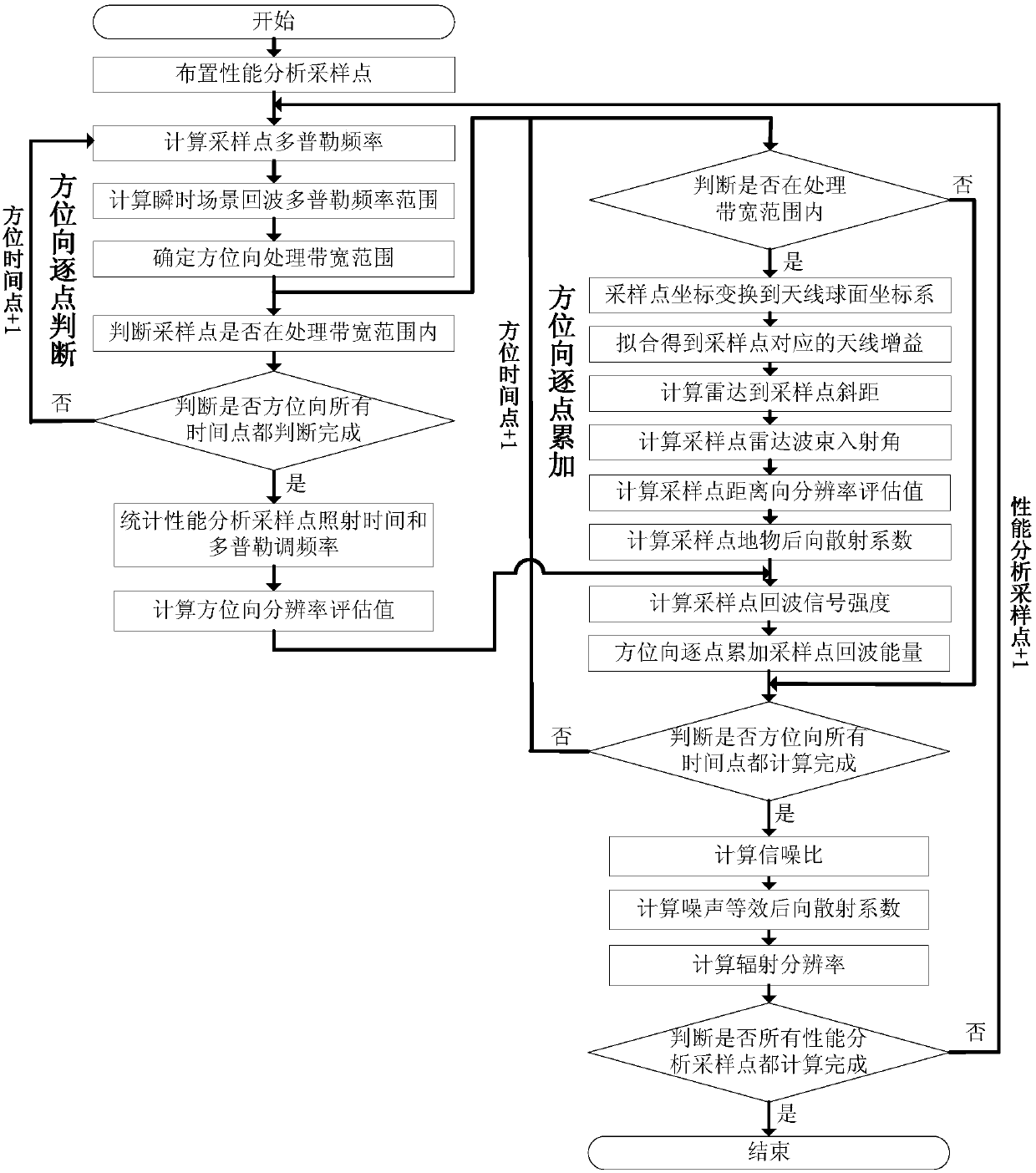

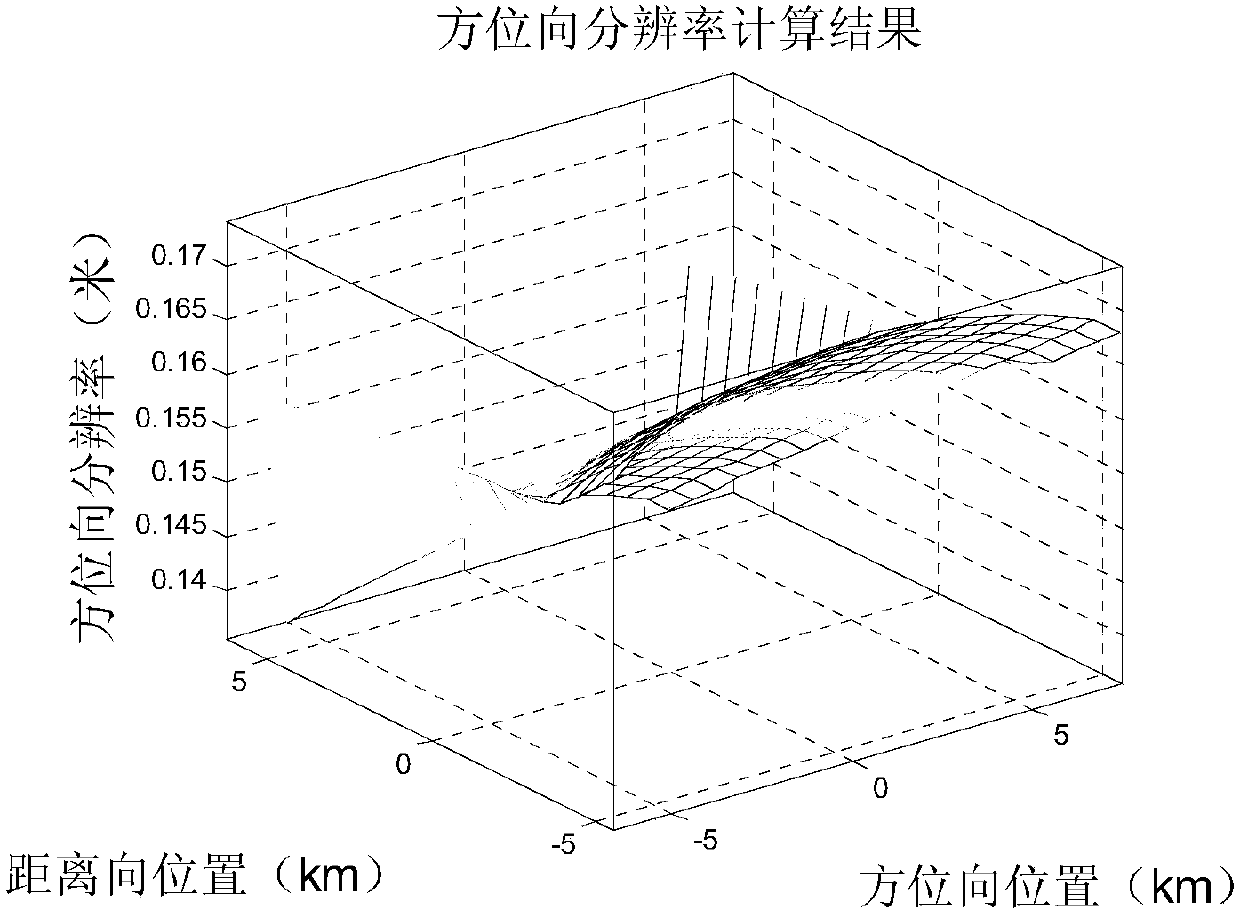

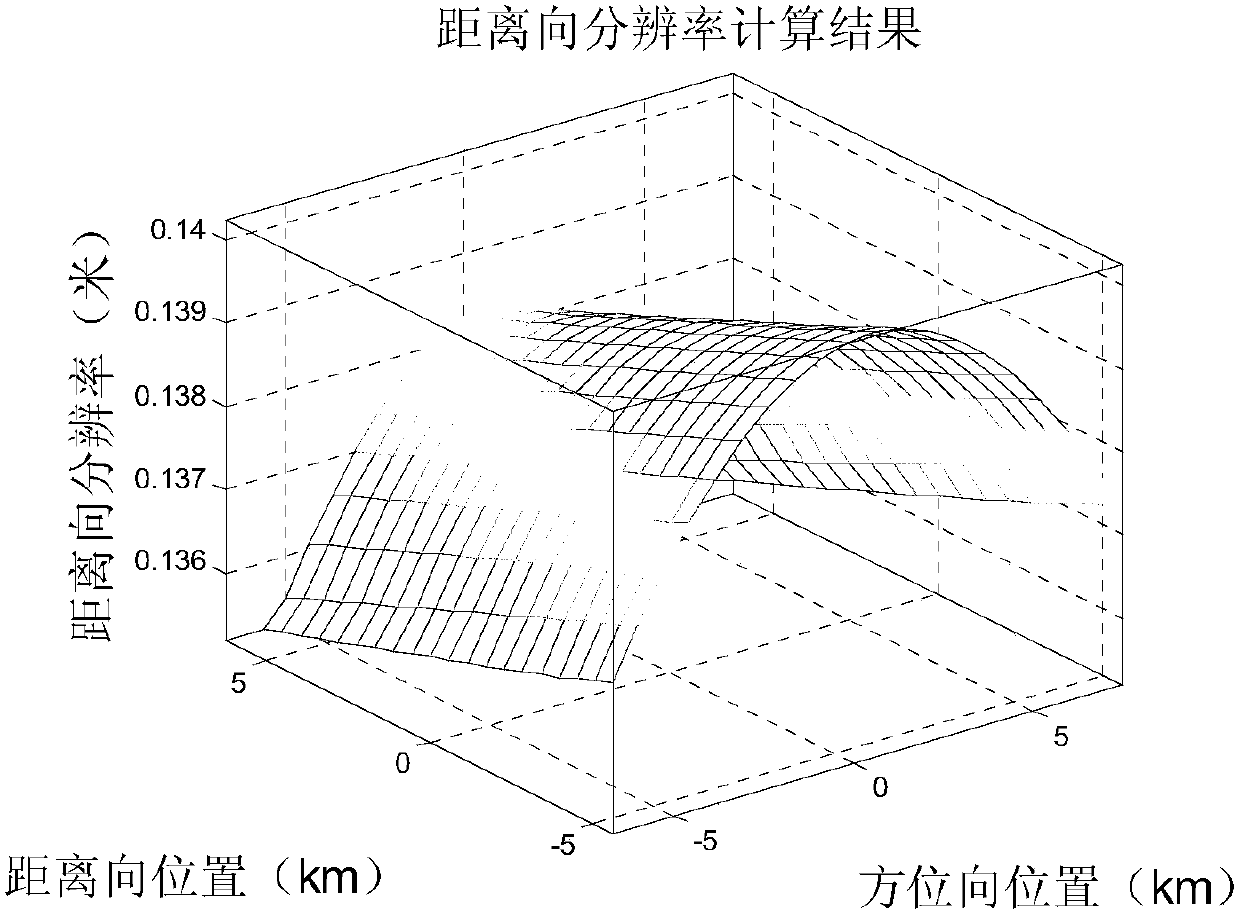

Method for analyzing radiation properties of high-resolution SAR (synthetic aperture radar) satellites

ActiveCN106353777AAccurately image echo signal energyFully reflect space variabilitySatellite radio beaconingSystems designSynthetic aperture sonar

The invention relates to a method for analyzing radiation properties of high-resolution SAR (synthetic aperture radar) satellites, and belongs to the technical field of overall designs of SAR satellites. The method has the advantages that radiation property indexes of various satellite-borne SAR working modes are accurately computed, and system design results are inspected and rechecked for the high-resolution SAR satellites and the high-resolution SAR satellites in variable-repetition-frequency modes in particular; echo signal energy starts to be computed point by point along imaging time from single-pulse radar equations, accordingly, time-dependent variation conditions of antenna gain, ground-object back-scattering coefficients, slope distances and radar scattering areas of the SAR satellites can be sufficiently reflected, accurate imaging echo signal energy can be obtained, and the accurate radiation property indexes of the high-resolution SAR satellites further can be obtained.

Owner:BEIJING INST OF SPACECRAFT SYST ENG

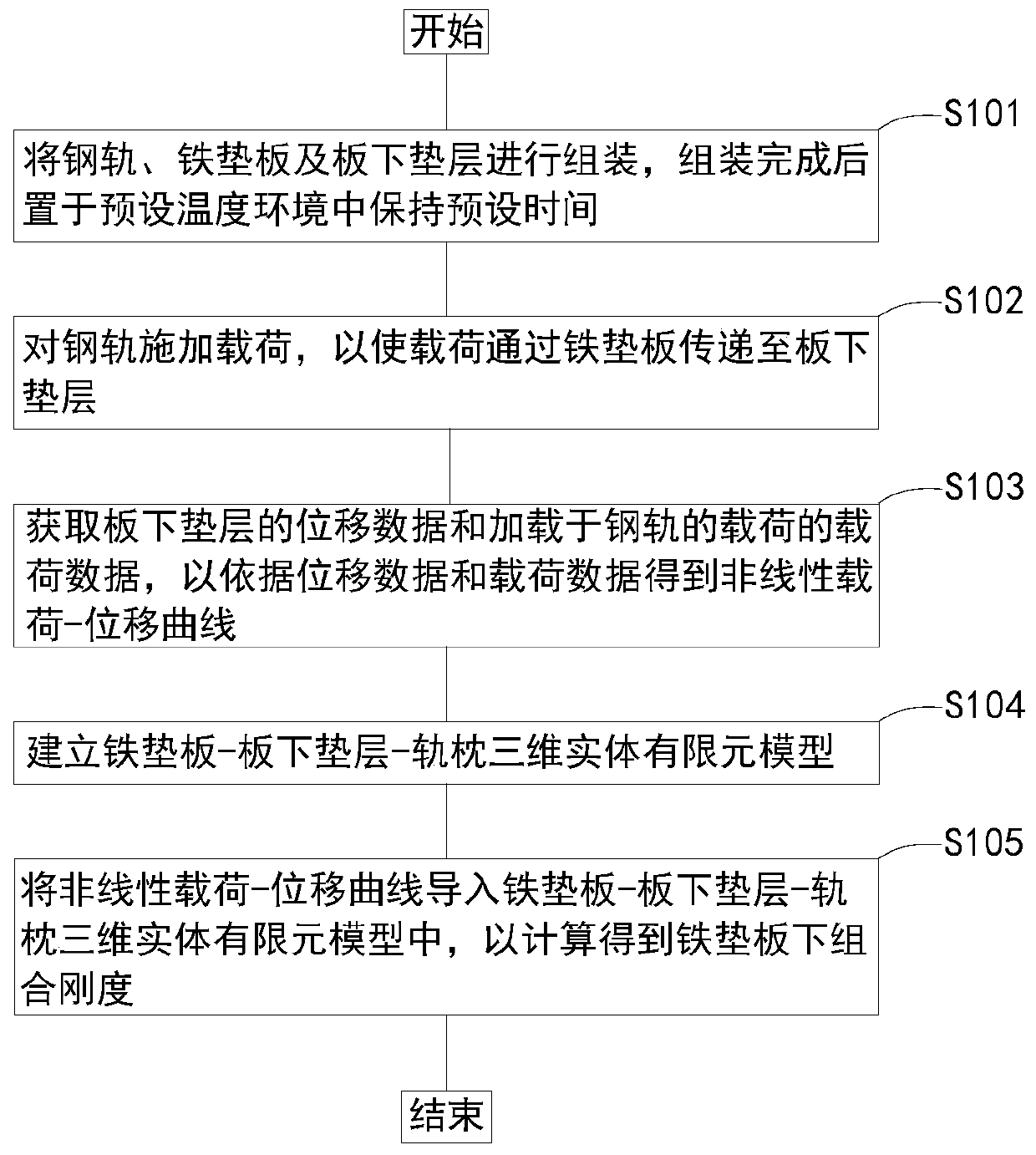

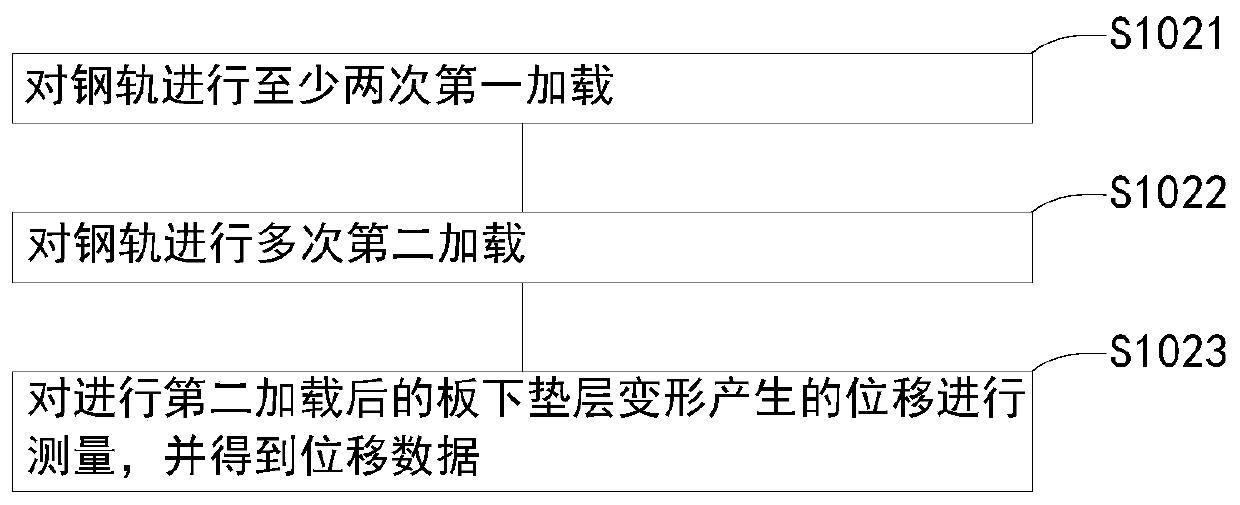

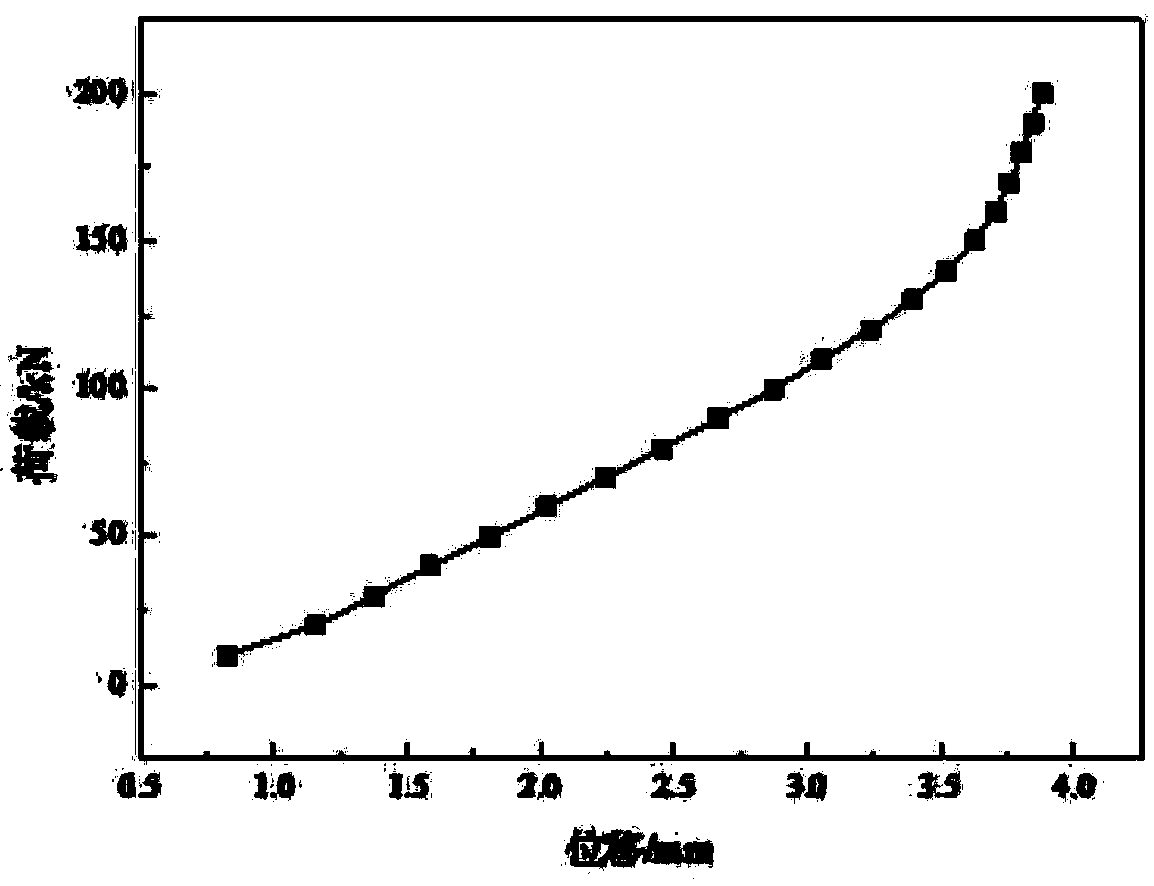

Method for designing lower combination stiffness of iron base plate of elastic separation type fastener system

InactiveCN110162846AAccurate design resultsDesign optimisation/simulationSpecial data processing applicationsElement modelEngineering

The invention discloses a method for designing the lower combination stiffness of an iron base plate of an elastic separation type fastener system, and relates to the technical field of track design.The method for designing the lower combined rigidity of the iron base plate of the elastic separation type fastener system comprises the steps of applying loads to a steel rail so that the loads can be transmitted to an under-plate cushion layer through the iron base plate, wherein the iron base plate, the under-plate cushion layer and a sleeper are sequentially arranged in a stacked mode from topto bottom, and the steel rail is arranged on the iron base plate; obtaining displacement data of the under-plate cushion layer and load data of a load loaded on the steel rail, and obtaining a nonlinear load-displacement curve according to the displacement data and the load data; establishing an iron base plate-under-plate cushion layer-sleeper three-dimensional entity finite element model; and importing the non-linear load-displacement curve into the iron base plate-under-plate cushion layer-sleeper three-dimensional entity finite element model so as to calculate the combined rigidity underthe iron base plate. According to the method for designing the lower combination stiffness of the iron base plate of the elastic separation type fastener system, more accurate design result can be obtained.

Owner:SOUTHWEST JIAOTONG UNIV +1

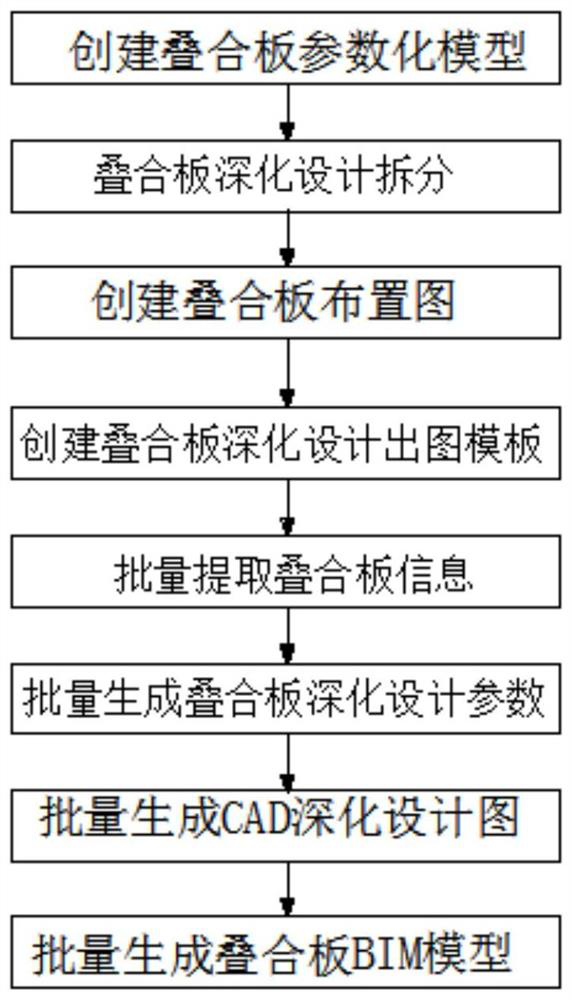

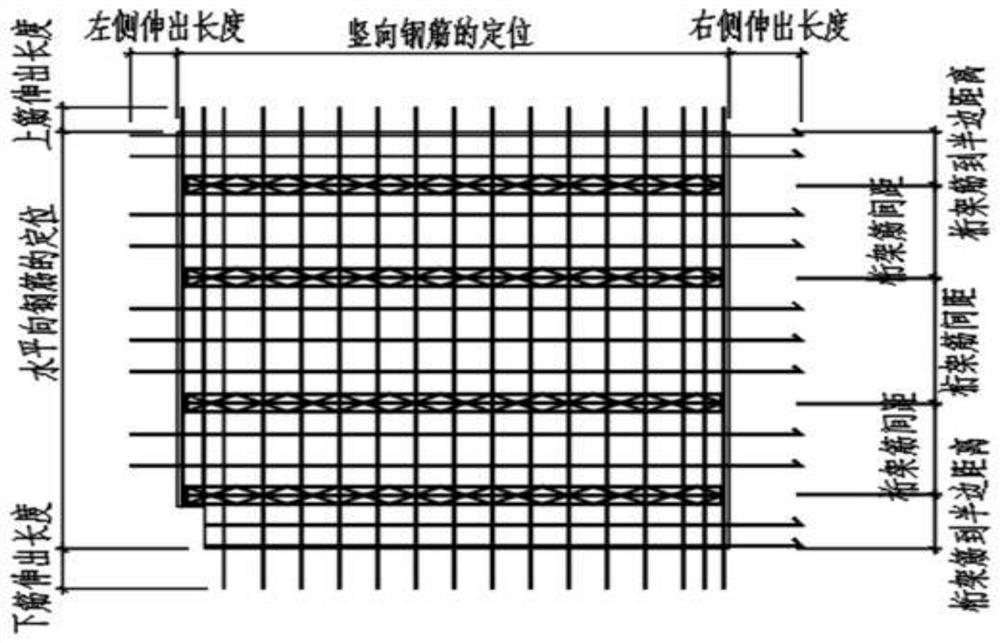

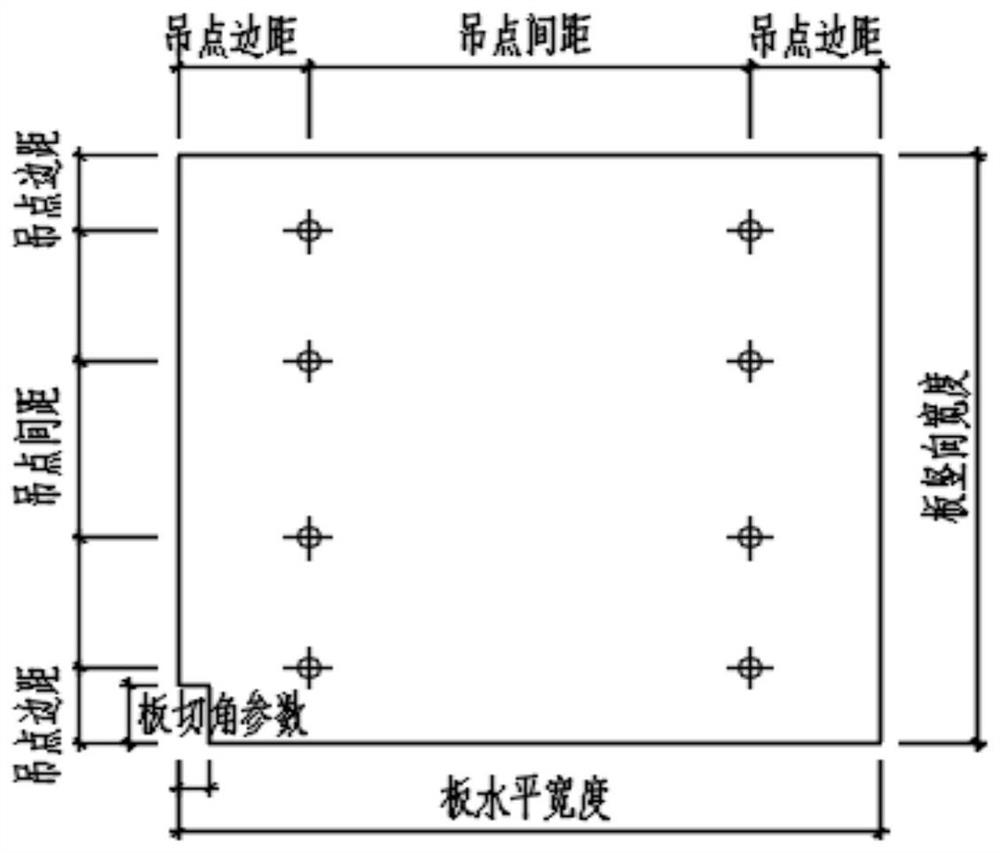

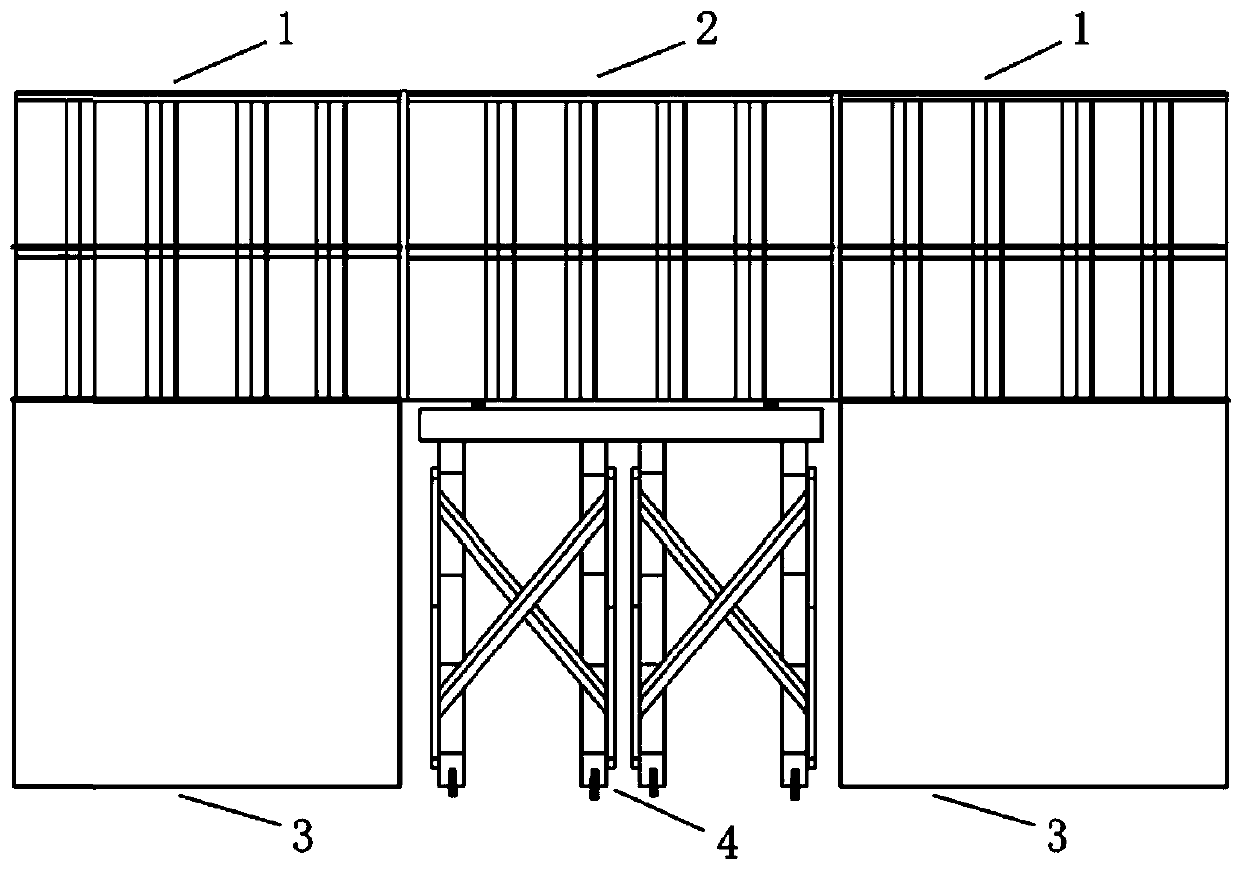

CAD and BIM-based batch deepening design method for fabricated structure laminated slabs

PendingCN112560134AImprove the quality of detailed designImprove design efficiencyGeometric CADFloorsLayoutStructural engineering

The invention discloses a CAD and BIM-based batch deepening design method for fabricated structure laminated slabs. The method mainly comprises the steps of creating a laminated slab parametric designmodel suitable for CAD and BIM; deepening design splitting of the laminated slab is manually completed; manually finishing a laminated slab plane layout drawing; creating a laminated slab to deepen and design a drawing template; extracting laminated slab boundary contour lines and corresponding information tables in the laminated slab plane arrangement diagram in batches through a program; generating laminated slab deepening design parameters in batches; generating laminated slab deepening design drawings based on CAD in batches; and generating laminated slab BIM models in batches by a program. By means of the implementation of the method, the deepening design quality and efficiency of the assembly type structure laminated slab can be remarkably improved, the deepening design result is stored in the two-dimensional code, and intelligent construction of the laminated slab is facilitated.

Owner:DALIAN UNIV OF TECH +1

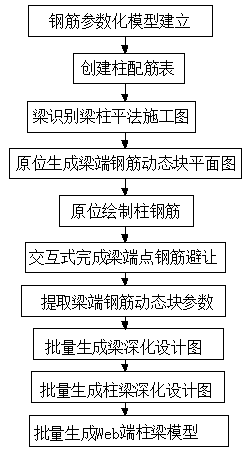

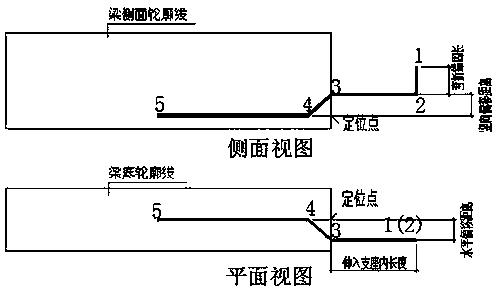

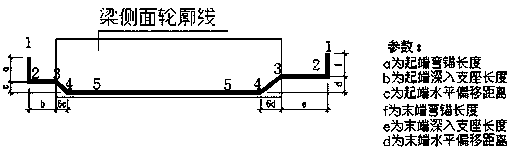

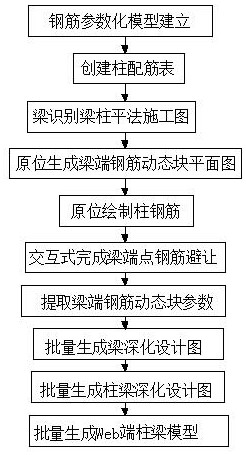

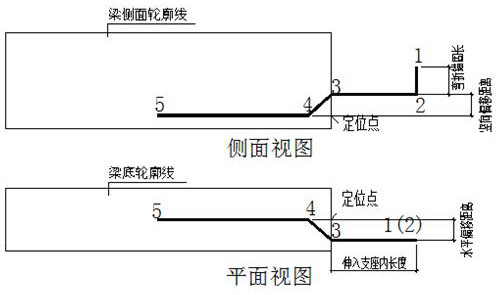

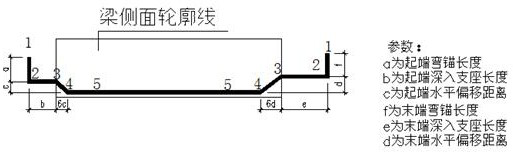

CAD and WebGl based deepen design method of fabricated construction prefabricated columns and laminated beams

The invention discloses a CAD and WebGl based deepen design method of fabricated construction prefabricated columns and laminated beams, and belongs to the technical field of intelligent buildings. The method comprises the steps of 1, establishing parameterized digital models of longitudinal bars, stirrups and lacing bars; 2, creating a column reinforcement table; 3, identifying a beam and columnconstruction general plan drawing, and extracting information of positioning and construction general plan method of beams, and information of column positioning and the column reinforcement table; 4,arranging dynamic blocks of steel bars at the ends of the beams; 5, drawing the longitudinal bars of the columns; 6, carrying out steel bar avoidance design at beam-column joints in the constructionplan drawing; 7, extracting information of the steel bar avoidance design at the beam-column joints, and generating a beam and column component database and a two-dimensional code; 8, generating CAD-based deepen design drawings of the prefabricated columns and the laminated beams in batches; and 9, generating Web-based deepen design drawings of the prefabricated columns and the laminated beams inbatches. The CAD and WebGl based deepen design method of the fabricated construction prefabricated columns and laminated beams can effectively improve quality and efficiency of the design of the fabricated construction prefabricated columns and the laminated beams.

Owner:SHENYANG POLYTECHNIC UNIV +1

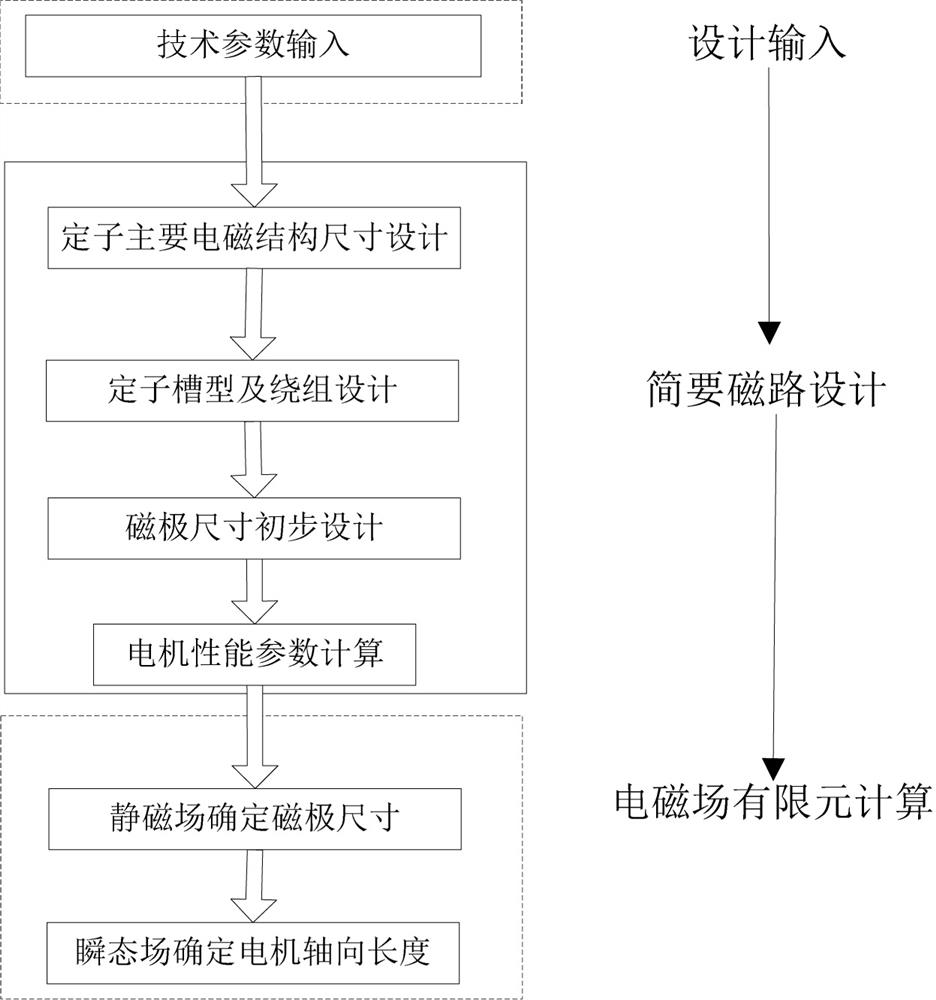

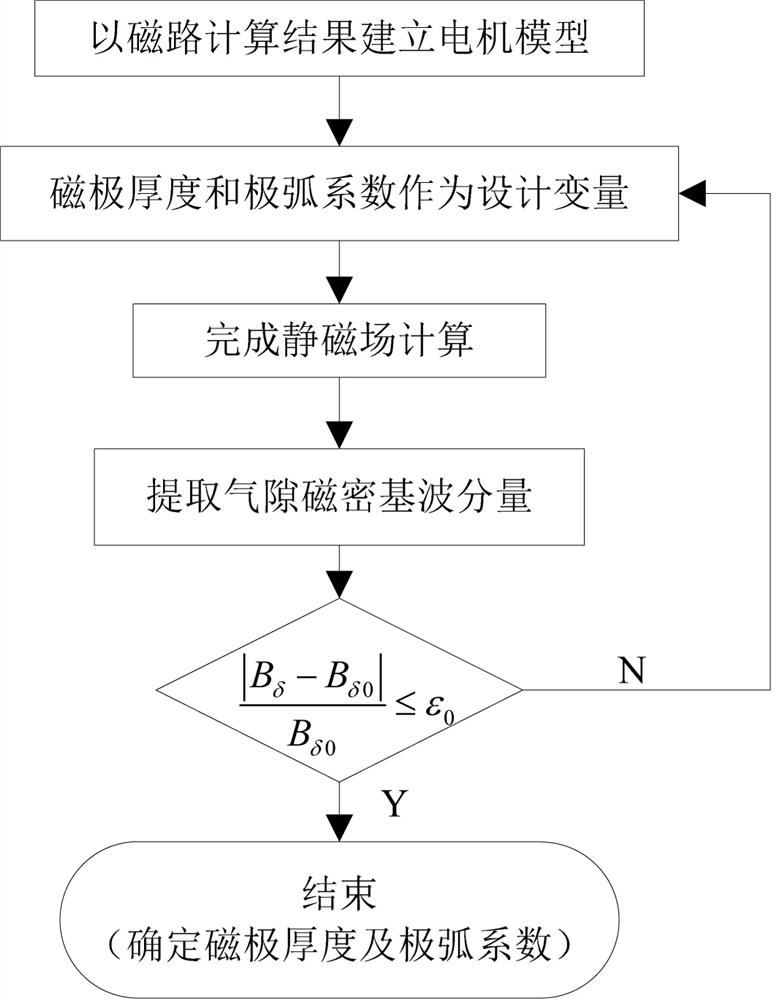

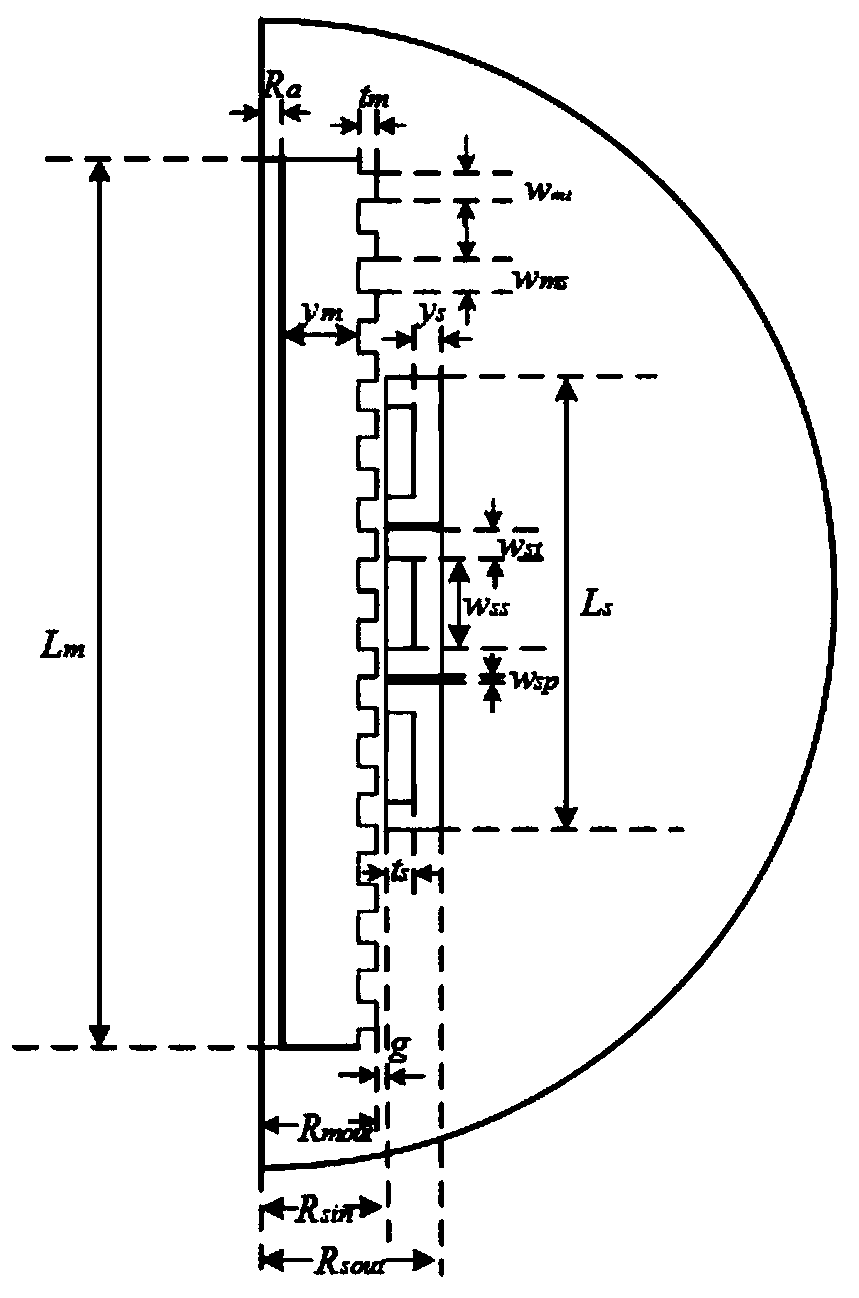

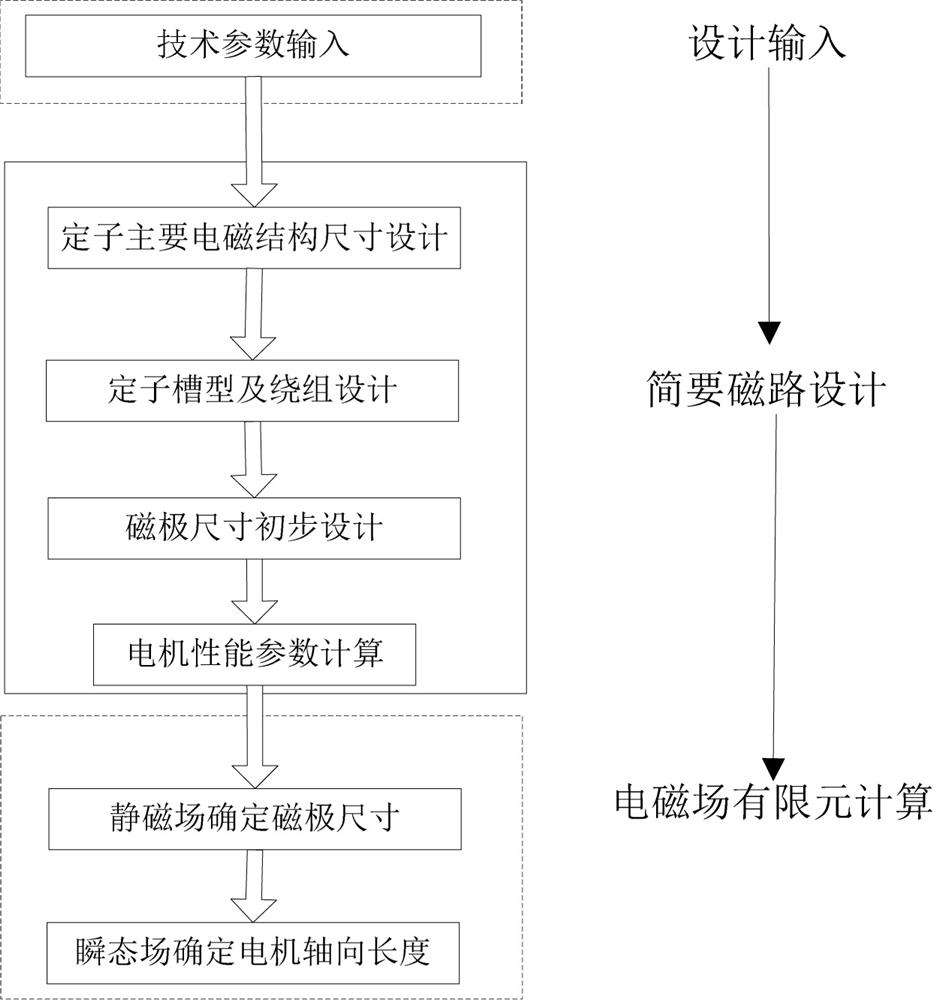

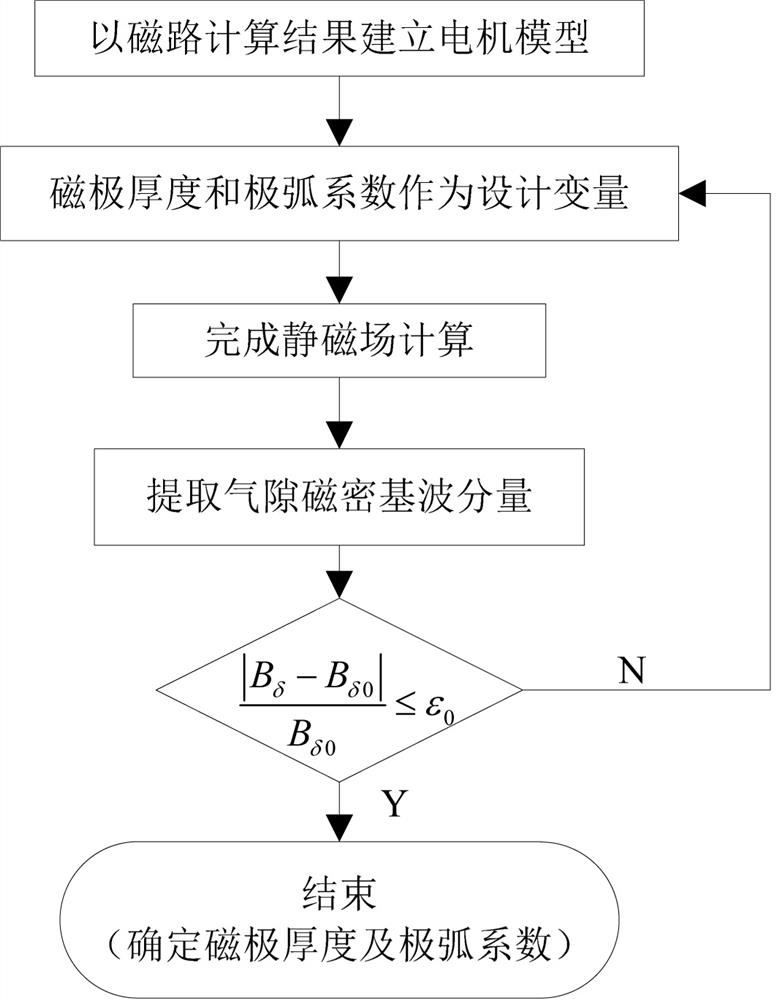

Electromagnetic design method of surface-mounted permanent magnet motor

ActiveCN112713729ATo overcome inaccurate coefficients and other deficienciesAccurate design resultsManufacturing stator/rotor bodiesElectric machineMagnetic poles

The invention discloses a surface-mounted permanent magnet motor electromagnetic design method, and the method comprises the steps of simple magnetic circuit design and electromagnetic field finite element calculation of a permanent magnet motor. The simple magnetic circuit design mainly takes the technical requirements of the motor as input, and according to the basic formula of the motor electromagnetic design, the size of a stator core of the permanent magnet motor and the initial size of a rotor magnetic pole are determined; the electromagnetic field finite element calculation comprises static magnetic field calculation and transient magnetic field calculation, wherein the static magnetic field calculation is used for determining the radial size of a rotor magnetic pole, and the transient magnetic field calculation is used for determining the axial length of the motor. The method provided by the invention is not limited by the size of the permanent magnet motor, overcomes the defects of inaccurate coefficient and the like in an empirical formula in the traditional motor design and calculation process, considers the saturation characteristic of the motor in calculation, improves the accuracy of a calculation result, and is particularly suitable for design analysis of a surface-mounted permanent magnet motor.

Owner:WUHAN MARINE ELECTRIC PROPULSION RES INST CHINA SHIPBUILDING IND CORP NO 712 INST

An Optimal Design Method for llc Resonant Converter

ActiveCN108631597BImprove efficiencyUniversalEfficient power electronics conversionDc-dc conversionDead timeParasitic capacitance

Owner:XI AN JIAOTONG UNIV

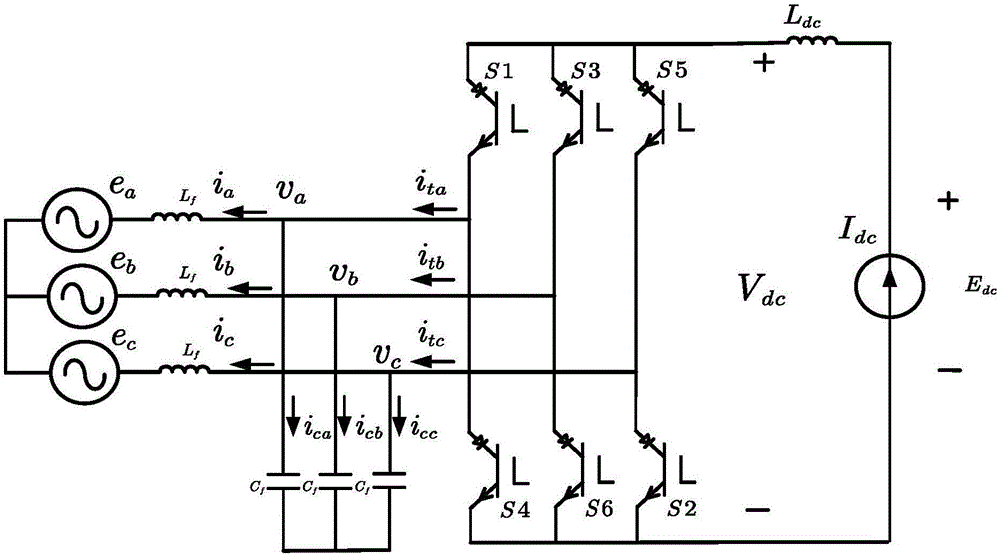

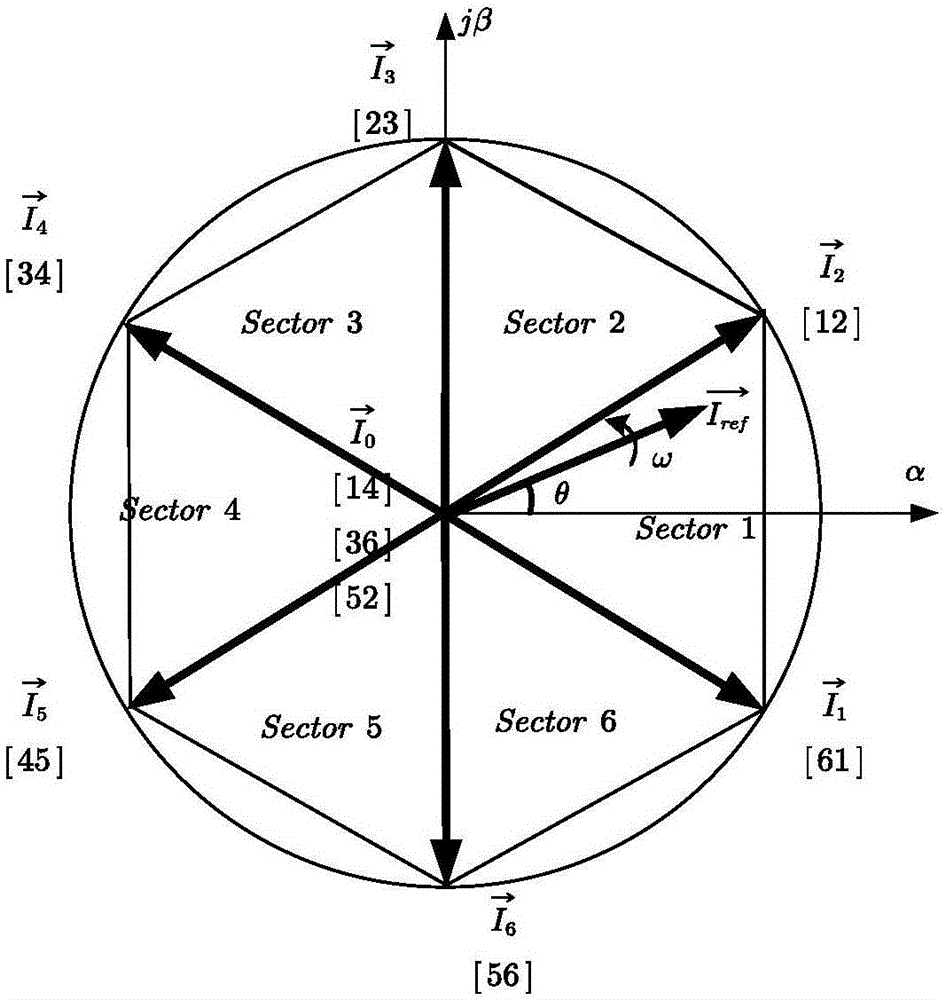

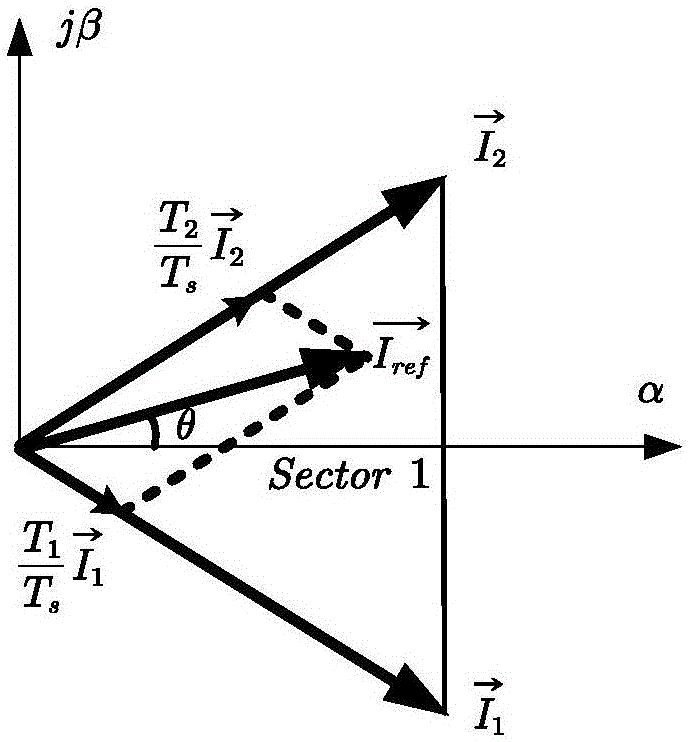

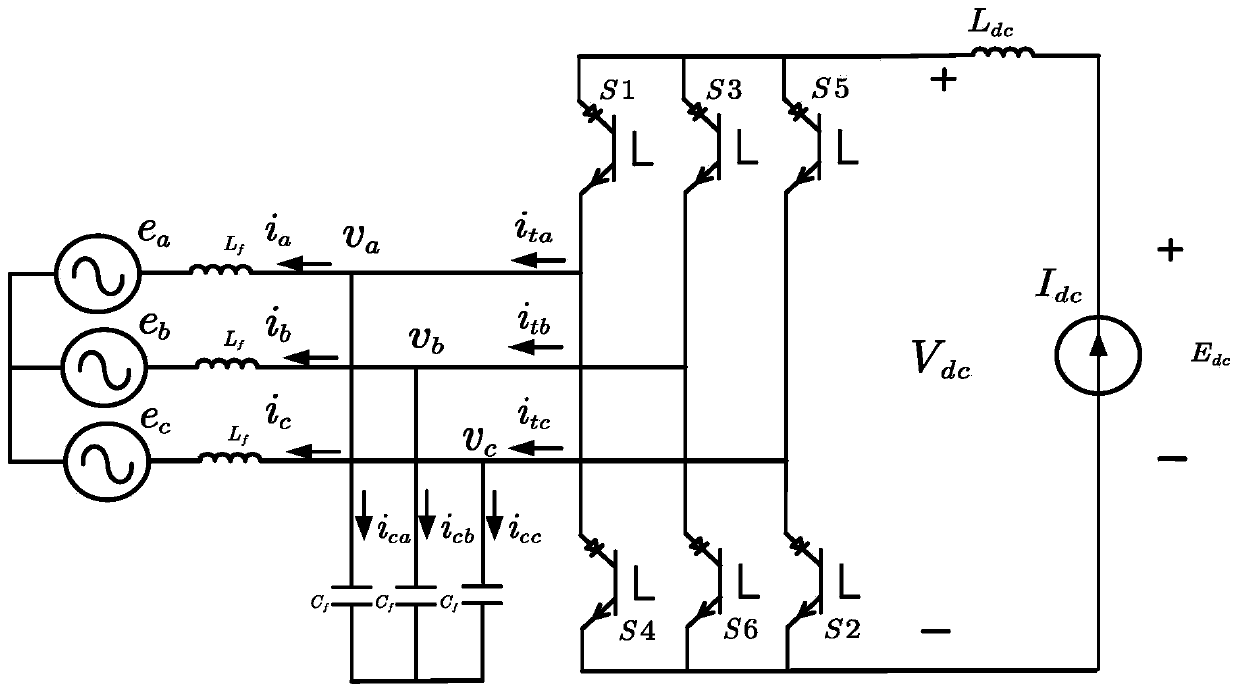

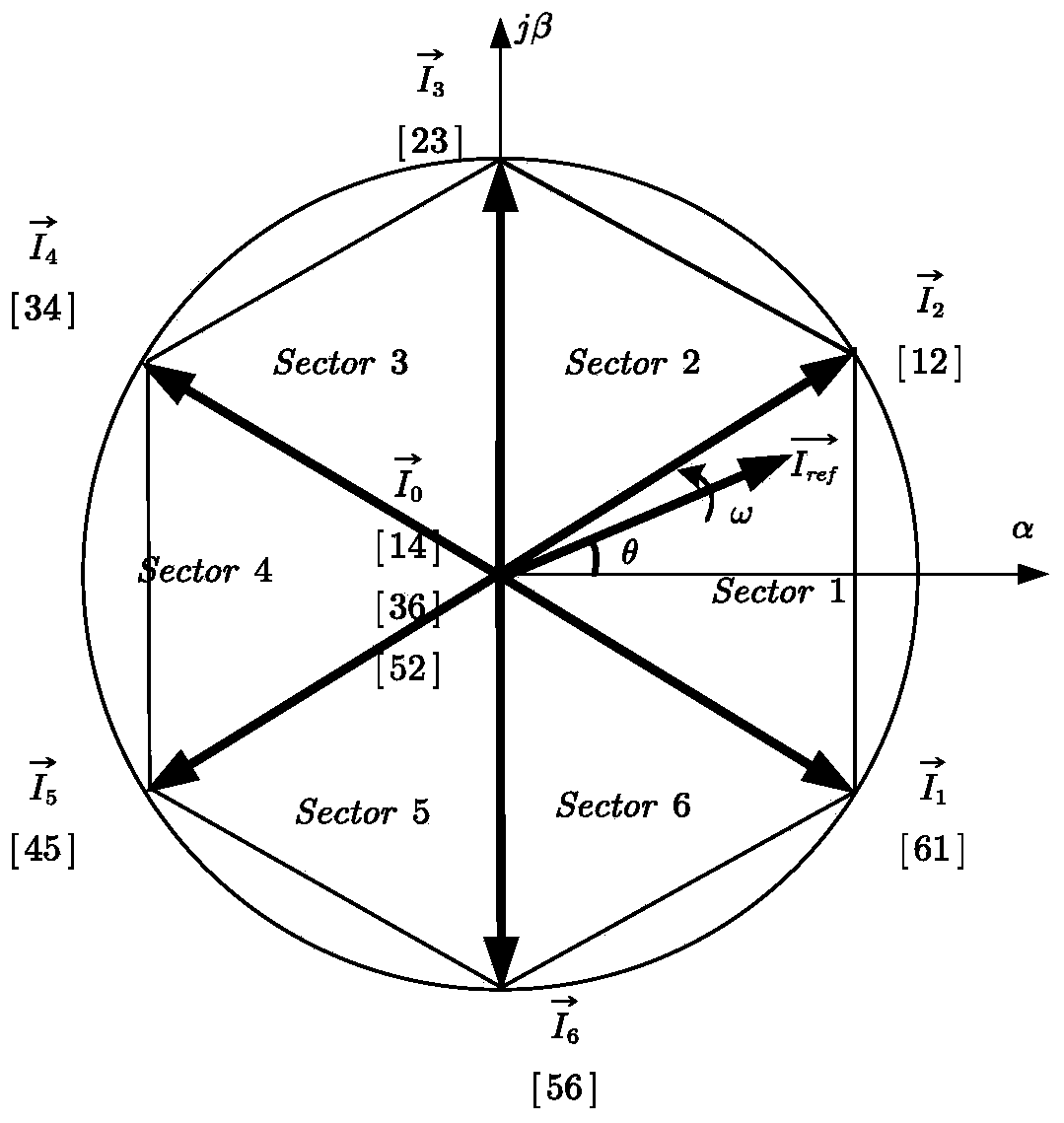

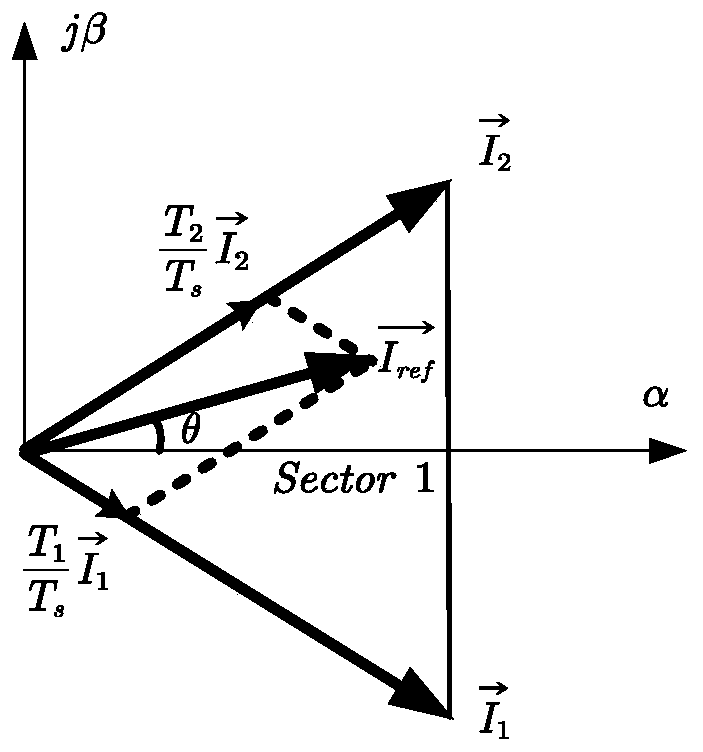

Novel design method for direct-current inductance of current source converter

The invention provides a novel design method for direct-current inductance of a current source converter. The method comprises the following steps: 1, calculating parameters of a system, comprising a converter alternating-voltage amplitude value Vtm, a converter alternating-current phase-A voltage initial phase gamma, a modulation ratio m and a reference current angular displacement initial value theta 0; 2, calculating the maximum value of a volt-second constant according to volt-second balance principles; 3, considering influences of different modulation methods for ripples, finding possible maximum volt-second constants, and taking the maximum value in the possible maximum volt-second constants as C; 4, calculating the direct-current inductance. The novel design method for the direct-current inductance of the current source converter disclosed by the invention overall considers influences of various factors, and design results are very accurate; compared with the traditional design method, the design value of the direct-current inductance can be greatly reduced under same design requirements of the direct-current current ripples to greatly reduce the cost and the size of the direct-current inductance.

Owner:SHANGHAI JIAODA INTELLECTUAL PORPERTY MANAGEMENT CO LTD +1

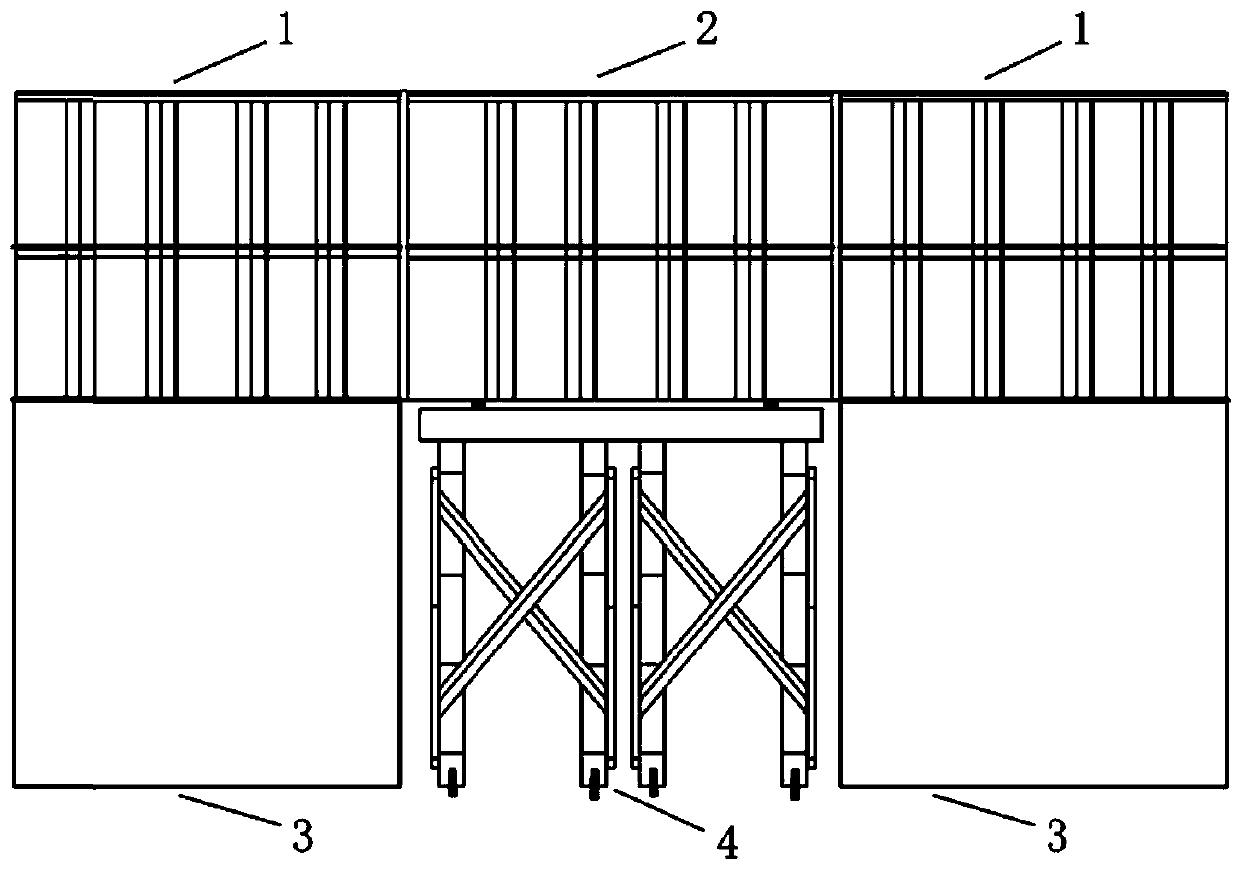

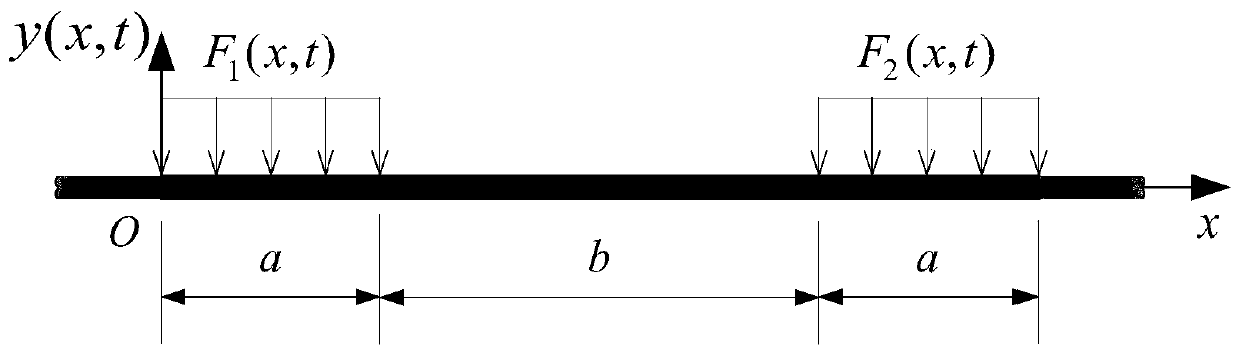

Model box design method for simulating ground motion space differential effect and model box

PendingCN111177908AImprove design efficiencyAccurate design resultsDesign optimisation/simulationClassical mechanicsEngineering

The invention relates to a model box design method for simulating a ground motion space differential effect and a model box. The design method comprises: designing the model box as an elastic beam system; simplifying a load acting on the model box as a simple harmonic traveling wave load; establishing a simplified calculation model and a load boundary condition of the model box; obtaining model box parameters for simulating the seismic space differential effect by utilizing integral transformation and a residue theorem; and designing the model box based on the model box parameters. Compared with the prior art, the method has the advantages of simplicity, convenience, reliability and the like, and can effectively realize the simulation of the ground motion differential effect in a multi-point vibration table test.

Owner:TONGJI UNIV

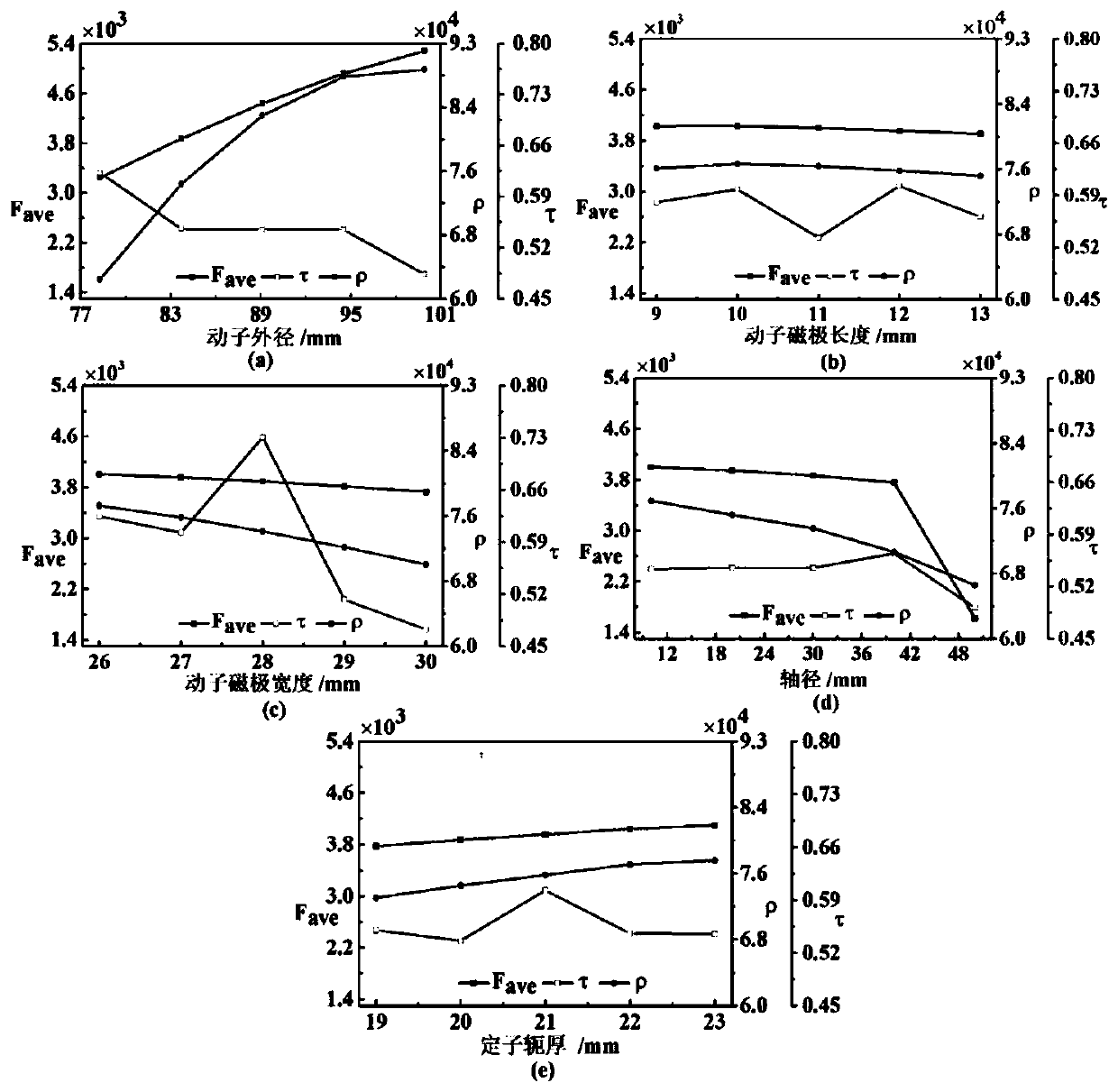

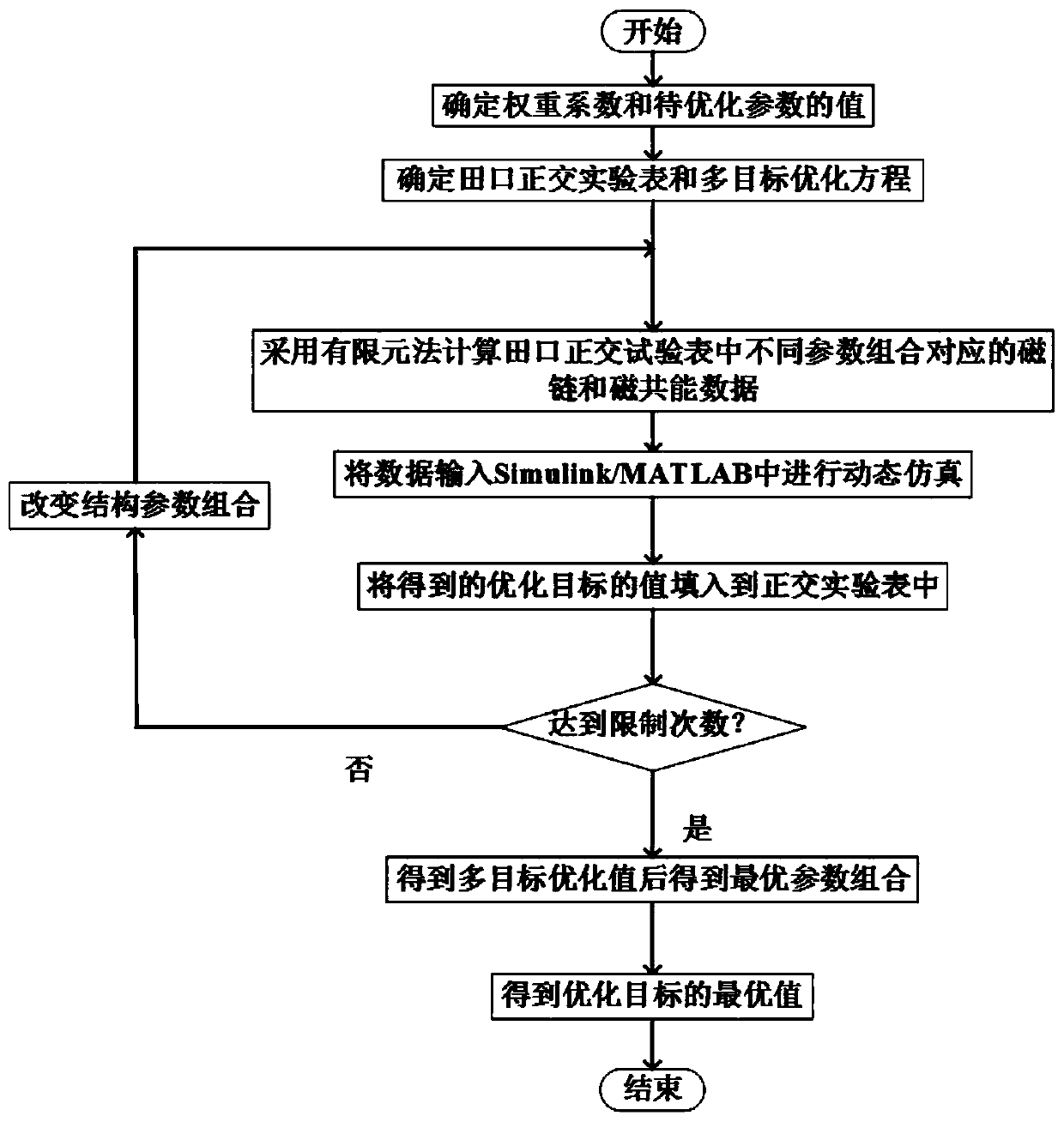

Novel multi-objective optimization method for three-phase cylindrical switched reluctance linear generator

PendingCN111581746AThe design result is objectiveReduce the number of calculationsGeometric CADDesign optimisation/simulationElectric machineryMulti objective optimization algorithm

The invention discloses a multi-objective optimization method for a three-phase cylindrical switched reluctance linear generator, and belongs to the field of motor design methods. Compared with a traditional single-objective optimization method, the multi-objective optimization algorithm has the advantages that multiple optimization objectives of the motor can be considered, and the comprehensiveperformance of the motor is improved. The method mainly comprises the steps of obtaining an optimization decision matrix according to values of optimization targets corresponding to determined to-be-optimized parameters under different values; calculating to obtain an objective weight coefficient corresponding to the optimization target through an improved entropy method; calculating an optimal weight coefficient considering the subjective emphasis of the designer; calculating comprehensive performance index values of the motor under different parameter combinations by utilizing a Taguchi algorithm; and selecting the parameter combination with the best comprehensive performance as the final structure parameter combination of the motor. The multi-objective optimization algorithm provided bythe invention obtains the optimal result with the least optimization times, has the advantages of short time consumption, simple calculation process and the like, and is suitable for multi-objectiveoptimization of all switched reluctance linear motors.

Owner:CHINA UNIV OF MINING & TECH

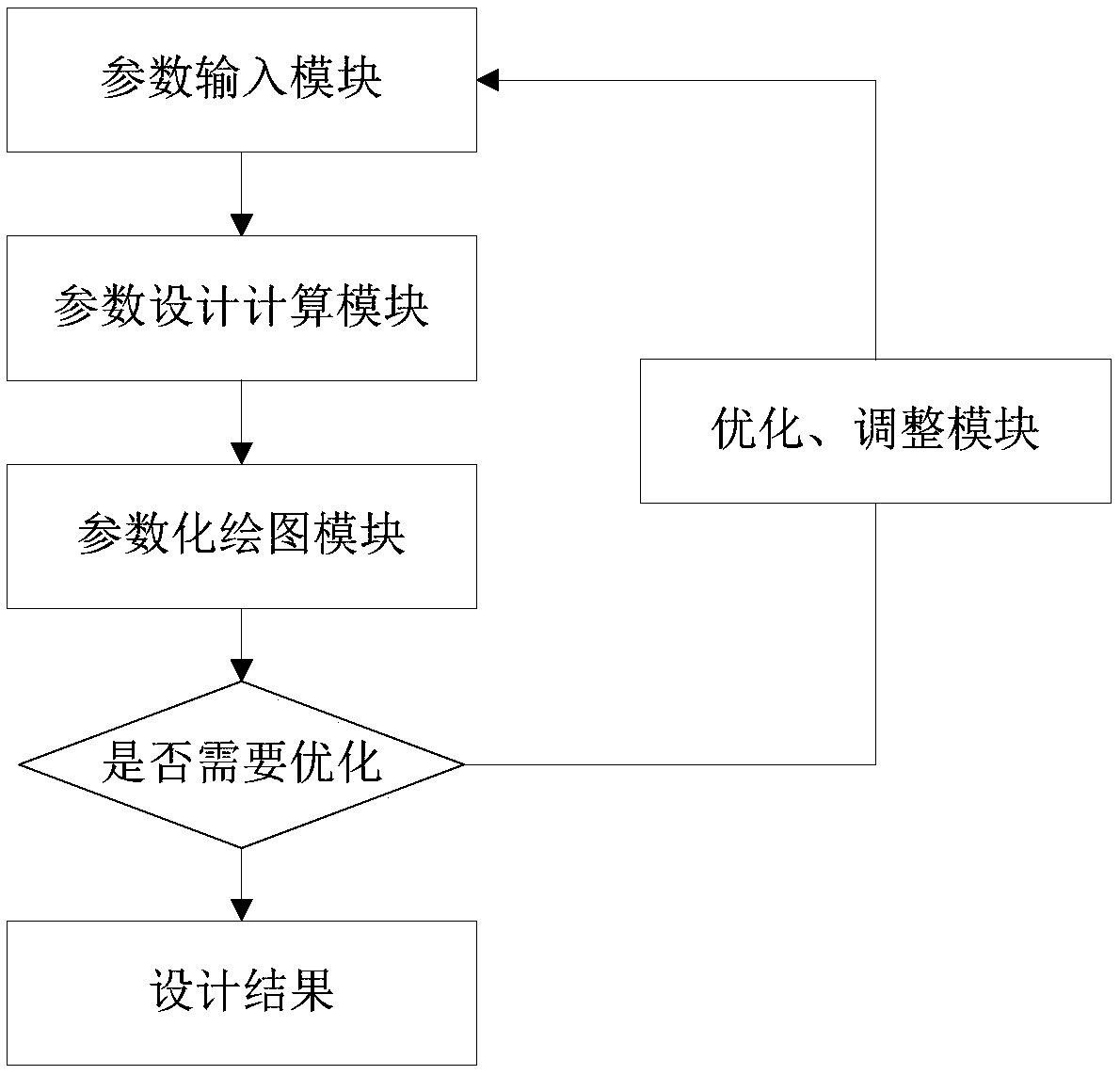

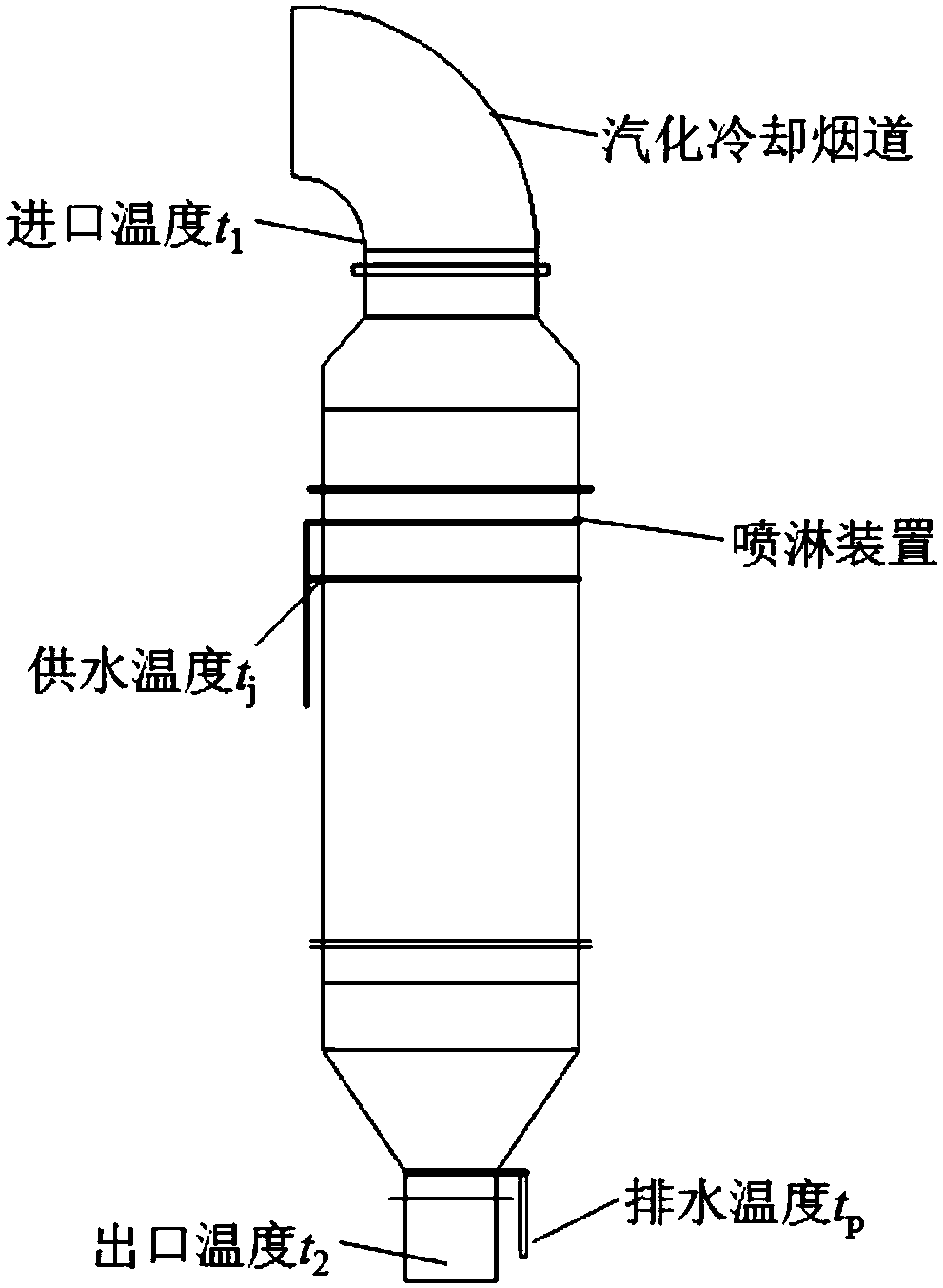

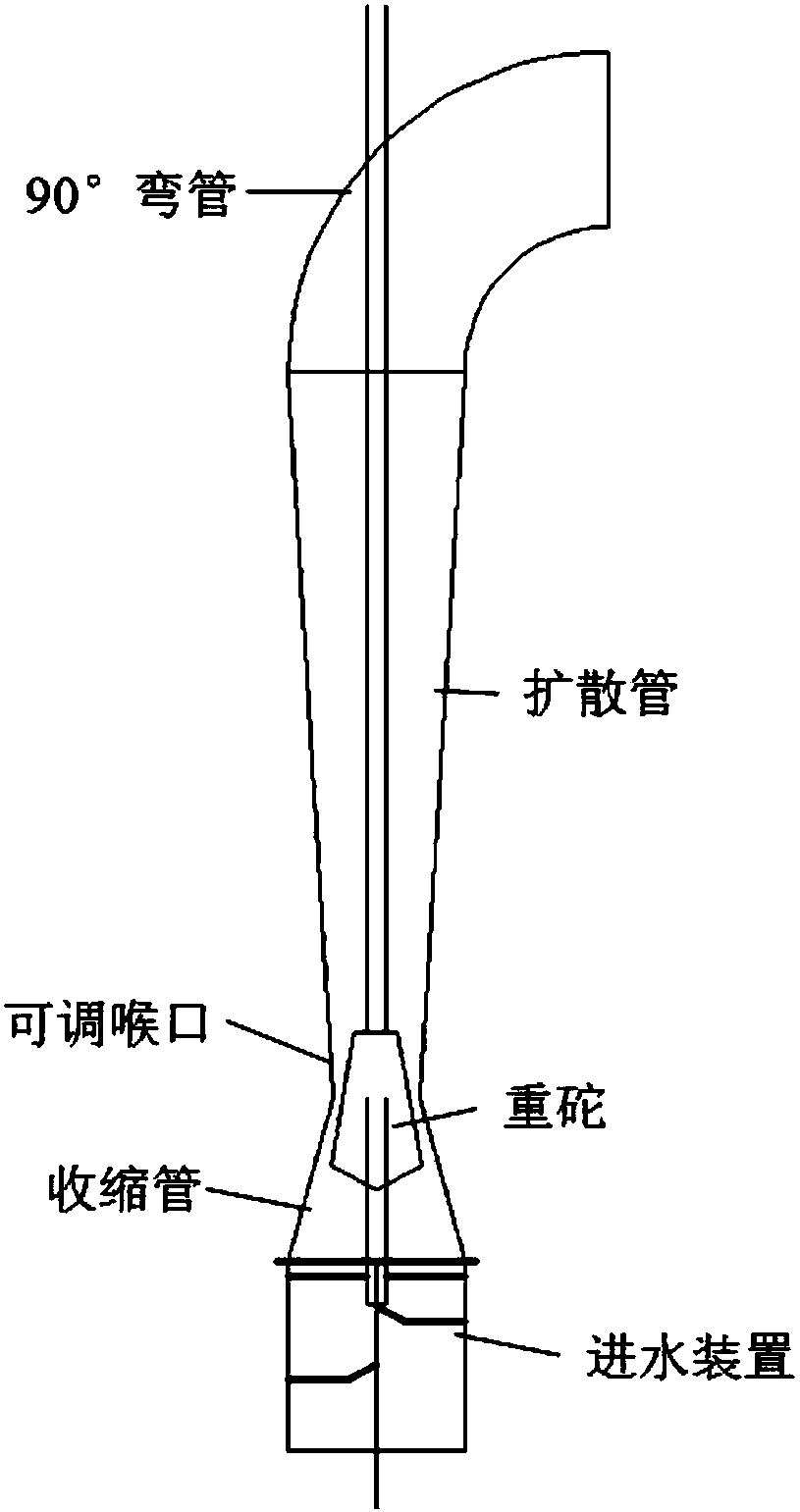

Converter primary dedusting OG system parameter computer aided design method

ActiveCN108416147AOptimal parameter designImprove the efficiency of aided designGeometric CADDesign optimisation/simulationComputer Aided DesignGraphics

The invention discloses a converter primary dedusting OG system parameter computer aided design method, and belongs to the technical field of OG system parameter design. The method comprises the stepsthat firstly, efficient scrubbing tower and circular seam venturi tube design parameters, an OG system operating parameter and a gas thermal property parameter are determined; mathematical models forparameter design computing of an efficient scrubbing tower and circular seam venturi tube are respectively established according to determined parameters; the determined parameters are called to respectively obtain geometrical parameters and operating parameters of the efficient scrubbing tower and circular seam venturi tube; AutoCAD is connected through VB, the AutoCAD automatically reads the geometrical variables, establishes corresponding graphic variables according to geometrical values of the geometrical variables, and paints and exports AutoCAD drawings of the efficient scrubbing towerand circular seam venturi tube. The converter primary dedusting OG system parameter computer aided design method has the advantage that the parameter input, parameter design computing, parametric drawing, optimization and adjustment of the efficient scrubbing tower and circular seam venturi tube can be performed for different working conditions to obtain higher design efficiency and an optimal parameter design.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

A detailed design method of prefabricated columns and composite beams based on cad and webgl

ActiveCN111395520BIn line with the habitImprove the quality of detailed designGeometric CADStrutsArchitectural engineeringDigital mockup

Owner:SHENYANG POLYTECHNIC UNIV +1

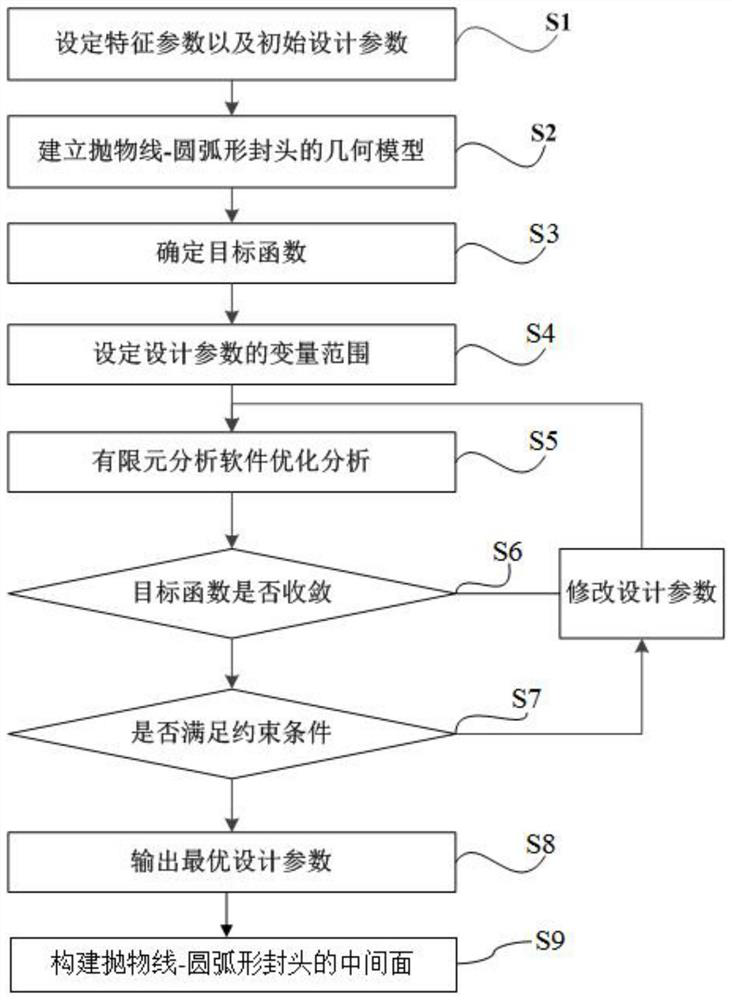

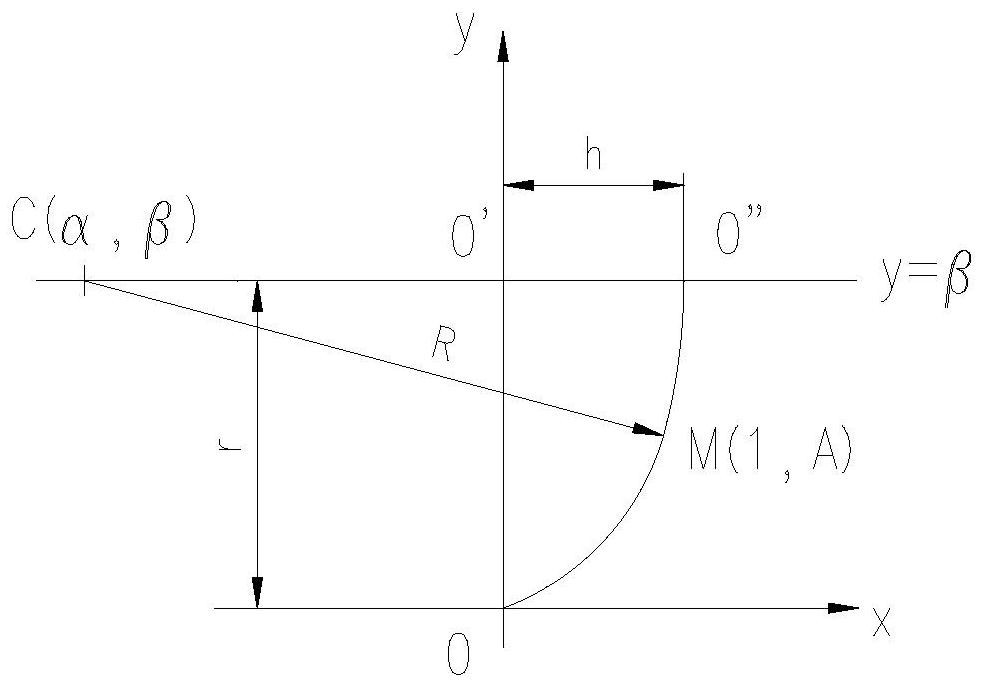

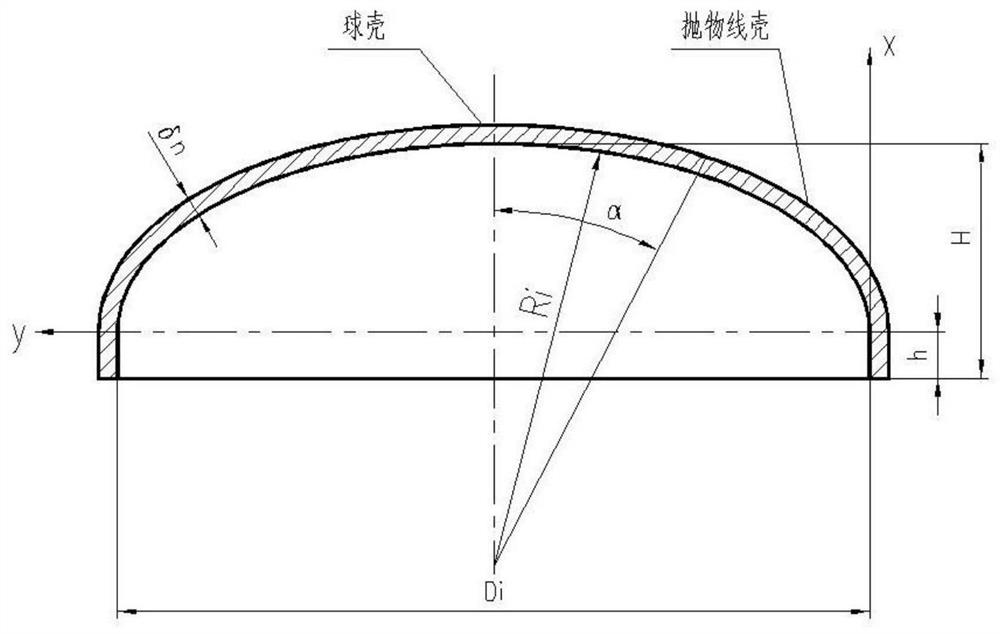

A method for optimal design of parabolic-arc-shaped head structure

ActiveCN107895098BShorten the timeSave materialGeometric CADDesign optimisation/simulation2D geometric modelFinite element analysis software

The invention provides an optimum structural design method for a parabolic-arc seal head. The method comprises the following steps: 1, setting characteristic parameters and initial design parameters of the parabolic-arc seal head; 2, establishing a two-dimensional geometric model according to the characteristic parameters and the initial design parameters; 3, determining a corresponding function at a minimal stress of the two-dimensional geometric model as an objective function; 4, setting a variable range of the initial design parameters; 5, performing optimized analysis on the initial designparameters by setting constraints and loads so as to obtain stress intensity values corresponding to the initial design parameters by using finite element analysis software; 6, substituting the stress intensity values into the objective function, judging whether the objective function is convergent and meets constraint conditions, if not, modifying the initial design parameters and returning to the step 5; and 7, obtaining the optimized design parameters when the objective function is convergent and meets the constraint conditions.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

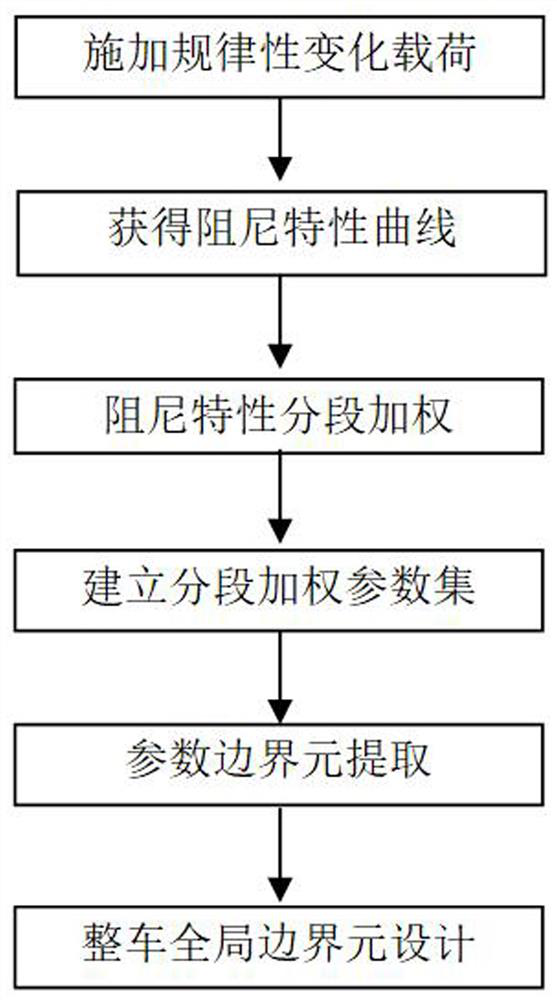

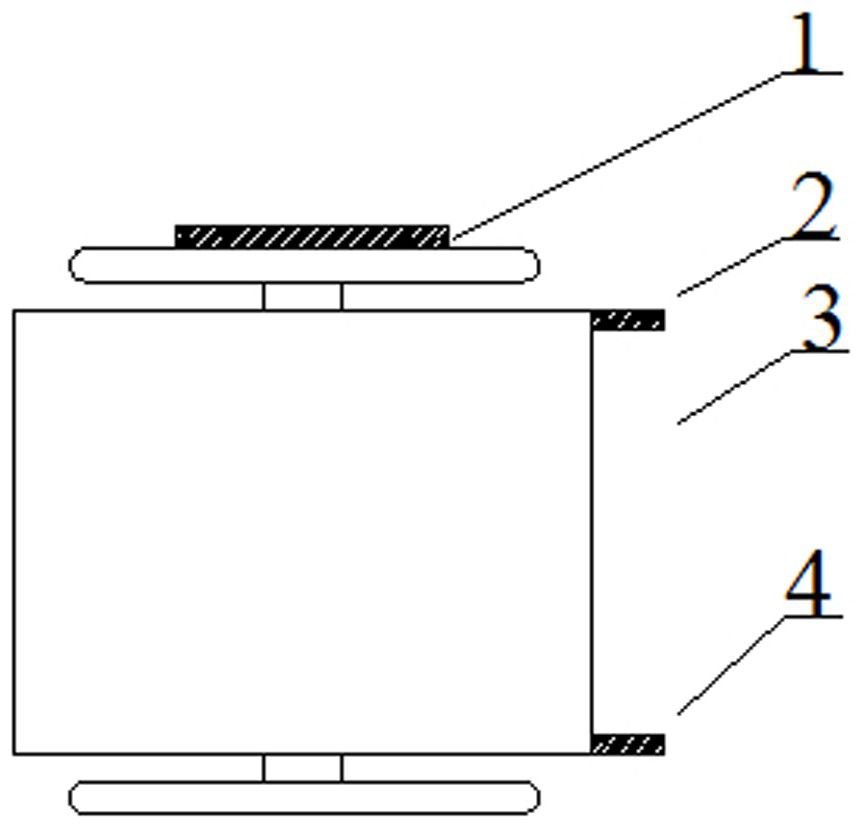

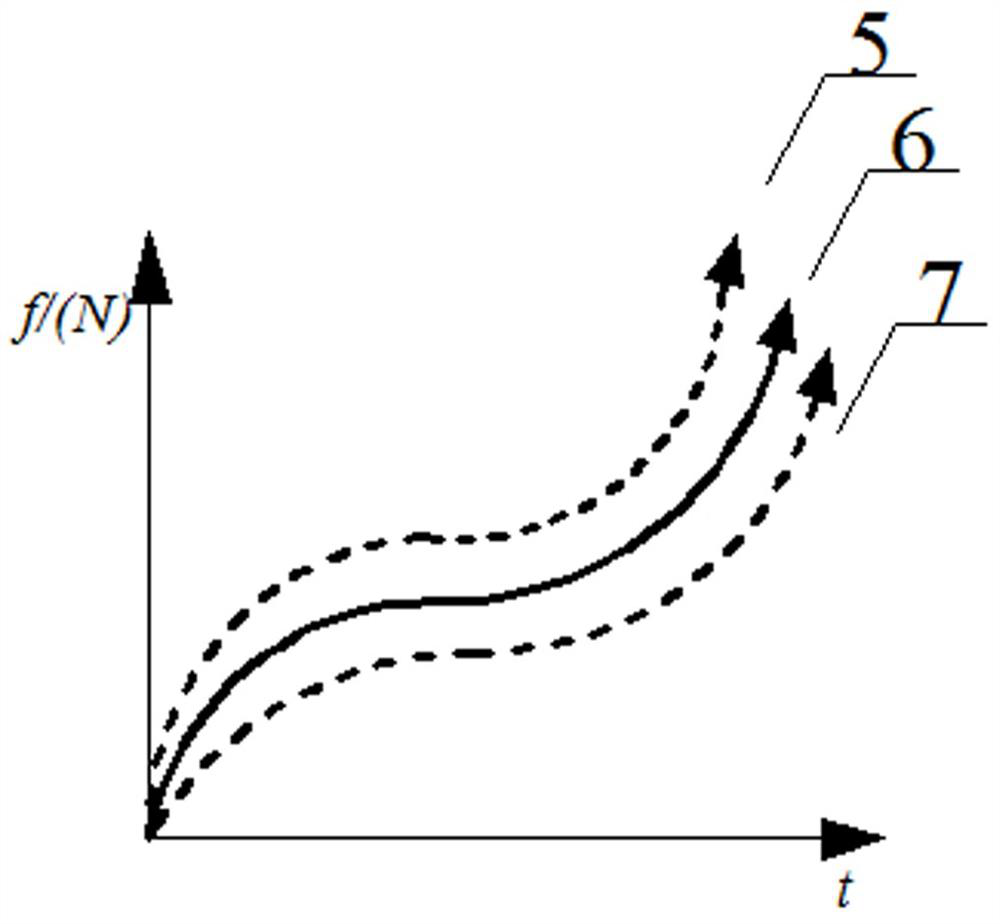

A Boundary Element Analysis Method Based on Commercial Vehicle Parameters

ActiveCN110046433BAvoid analysisIt is convenient for later adjustment referenceGeometric CADSustainable transportationControl theoryBoundary element analysis

The invention discloses a boundary element analysis method based on parameters of a commercial vehicle, which is characterized in that it comprises the following steps: 1) applying a regularly changing load; 2) obtaining a damping characteristic curve; 3) segmental weighting of the damping characteristic; 4 ) to establish a segmented weighted parameter set; 5) parameter boundary element extraction; 6) global boundary element design of the vehicle. This method can reasonably and accurately design the nonlinear damping, improve the accuracy of nonlinear scaling and matching, save the development cycle and cost, reduce the tuning cycle and facilitate the formation of a standard parameter scaling database for the model, which is convenient for the reduction of the same model. Vibration design provides a reference.

Owner:GUILIN UNIV OF ELECTRONIC TECH

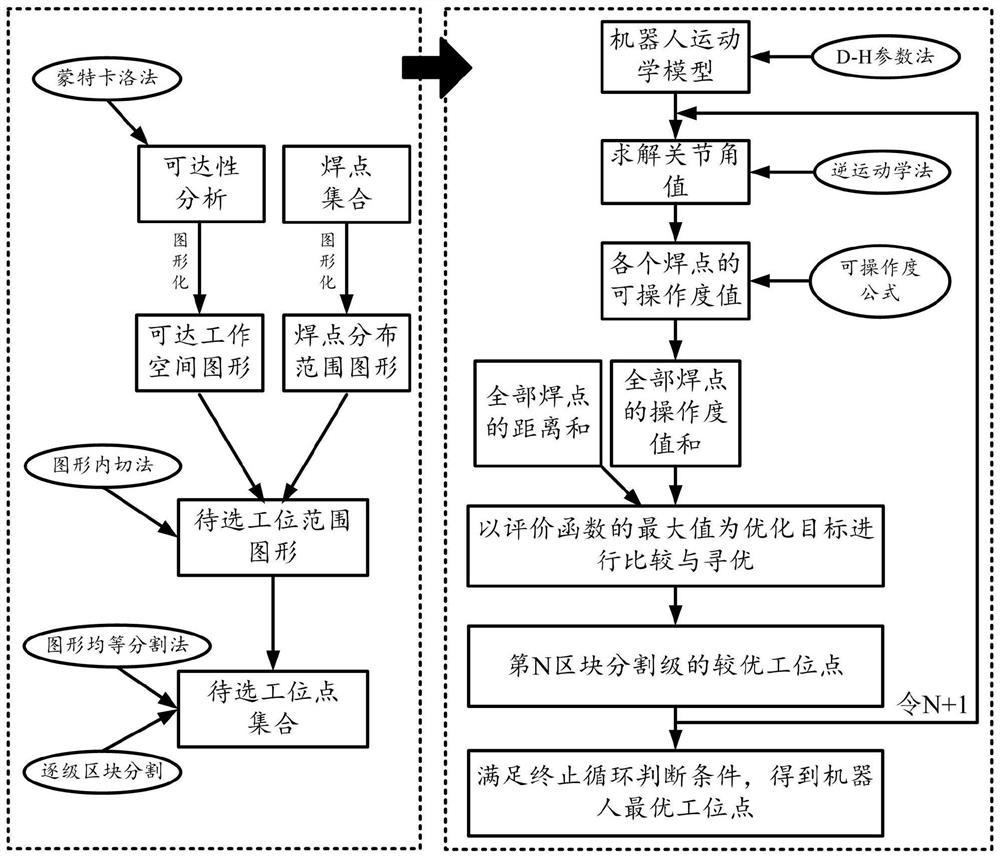

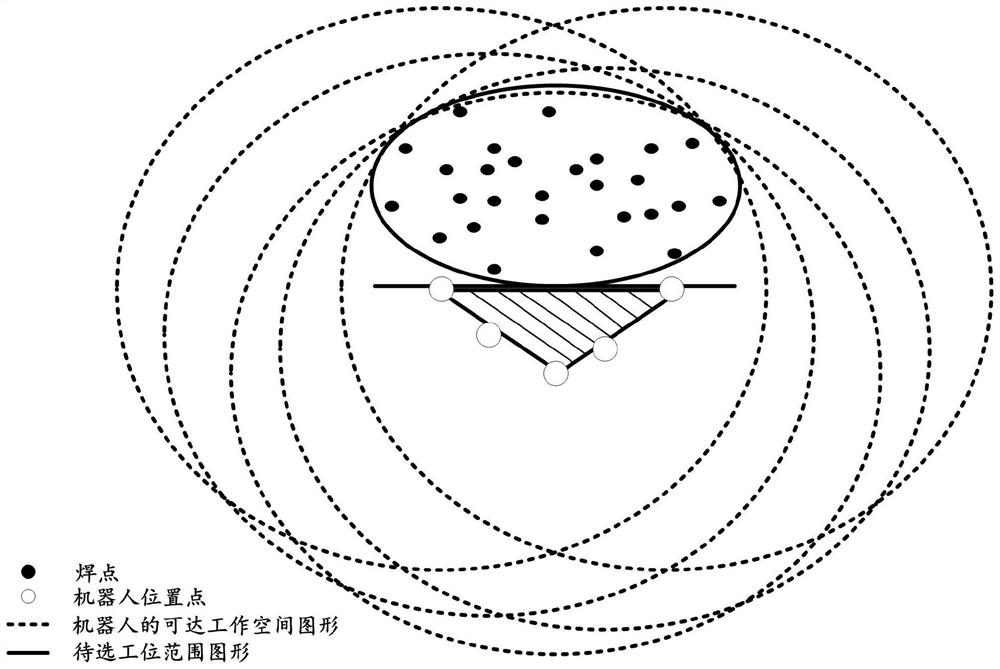

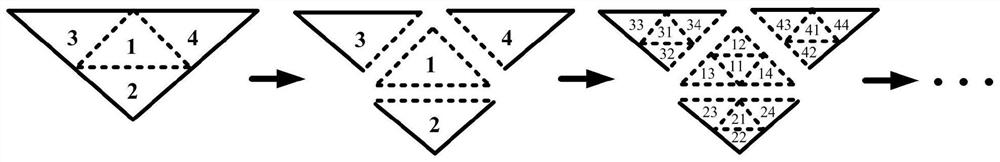

Robot station design method applied to welding assembly line

ActiveCN111716046AImprove welding utilizationComprehensive considerationWelding/cutting auxillary devicesAuxillary welding devicesControl engineeringRobot kinematics

The invention relates to a robot station design method applied to a welding assembly line. The robot station design method applied to the welding assembly line comprises the following steps that a welding point distribution range pattern and a reachable working space pattern of a robot are determined; the welding point distribution range pattern and the reachable working space pattern are used forobtaining a station range pattern to be selected; a pattern equal segmentation method is used for performing step-by-step block segmentation on the station range pattern to be selected to obtain a station point set to be selected; according to a robot kinematics model and a robot inverse kinematics method, the distance sum of each welding point of a station point to be selected and the sum of theoperability values of the welding points are solved; and a maximum value of the evaluation function based on an operability index and a distance index is used as an optimization target, the optimal station point of the robot is found through loop iteration, and the station design of the welding assembly line robot is achieved. The robot station design method applied to the welding assembly line has reasonable conception and novel conception, reasonable design of the welding assembly line robot station is achieved, the welding utilization rate of the welding robot can be improved, the flexibleand efficient production of the welding assembly line is achieved, and the practicability is relatively high.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

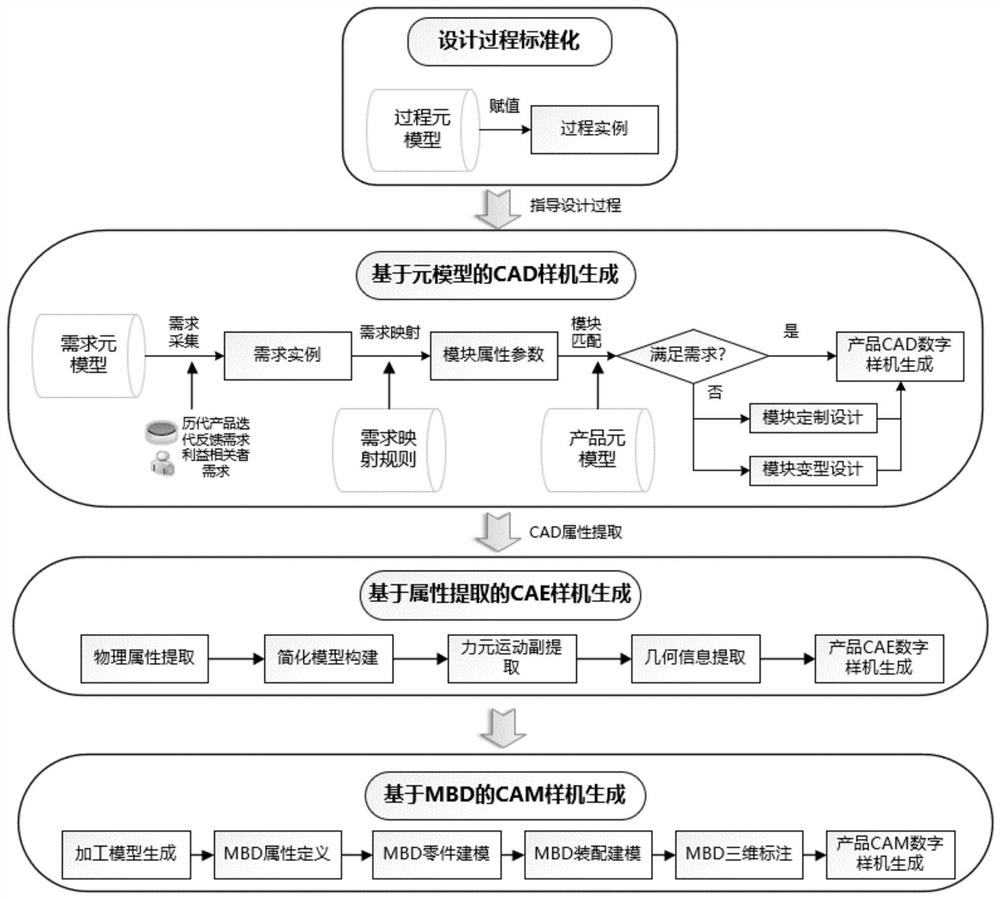

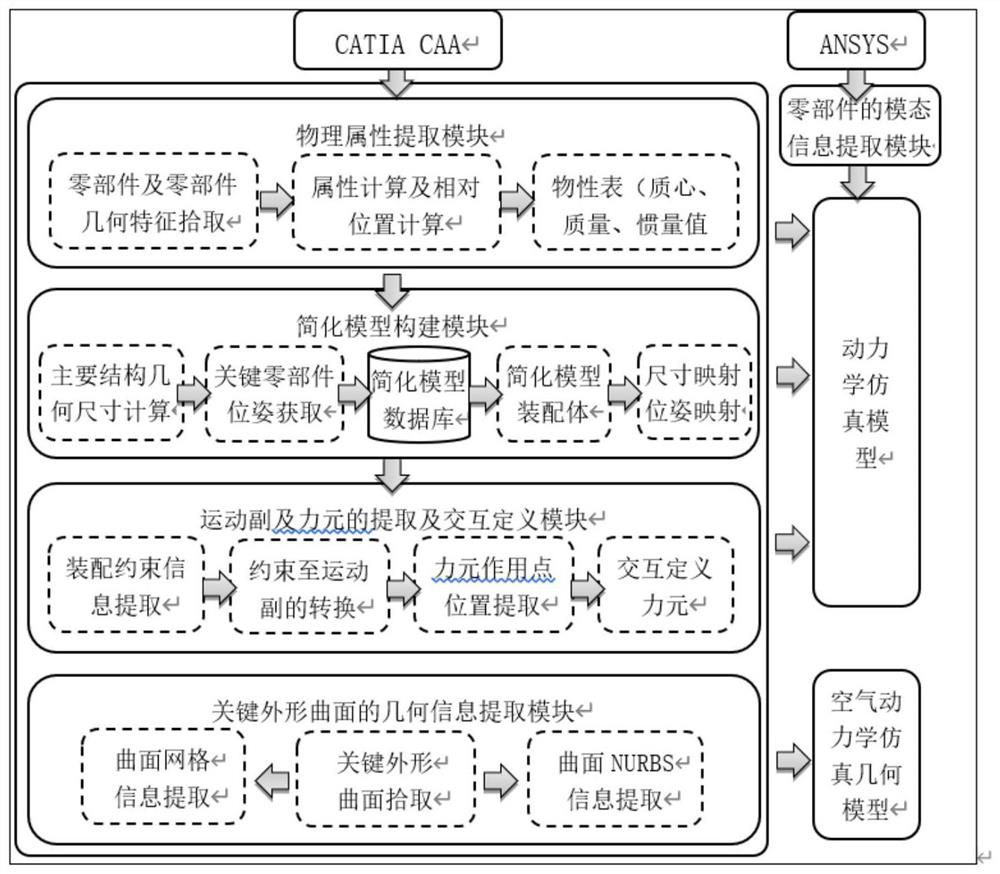

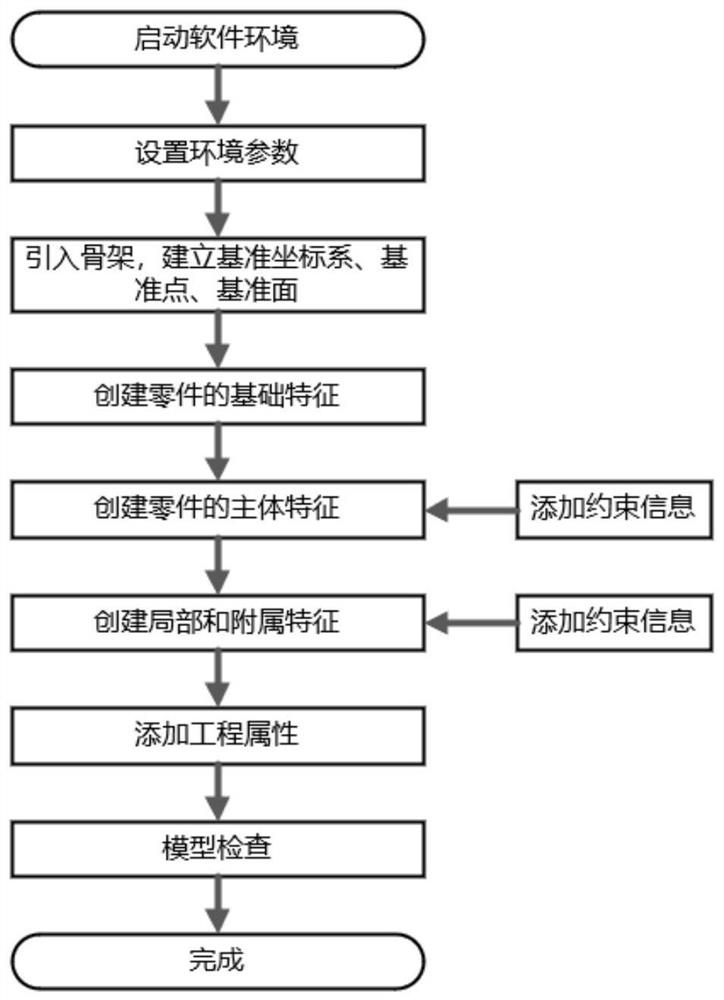

Complex product digital prototype generative design method based on meta-model

ActiveCN114861340AAccurate design resultsEnsure design rationalityGeometric CADDesign optimisation/simulationGenerative DesignReusability

The invention relates to a meta-model-based complex product digital prototype generative design method. Comprising the following steps: S1, standardizing a design process; s2, generating a CAD digital prototype based on a meta-model; s3, generating a CAE digital prototype based on attribute extraction; s4, generating a CAM digital prototype based on MBD; according to the complex product digital prototype generative design method provided by the invention, uniqueness, consistency, reusability and integration of complex product customer demands in a product full life cycle stage are ensured, sharing, integration and application of complex equipment demand information are facilitated, and demand-driven rapid design of complex products is realized.

Owner:SOUTHWEST JIAOTONG UNIV

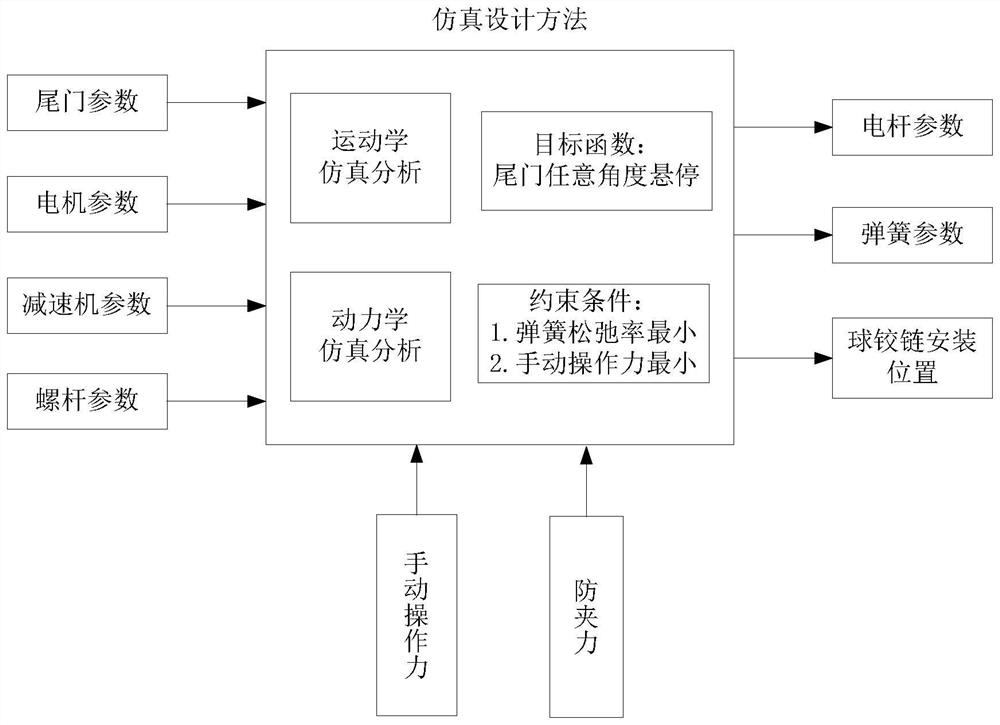

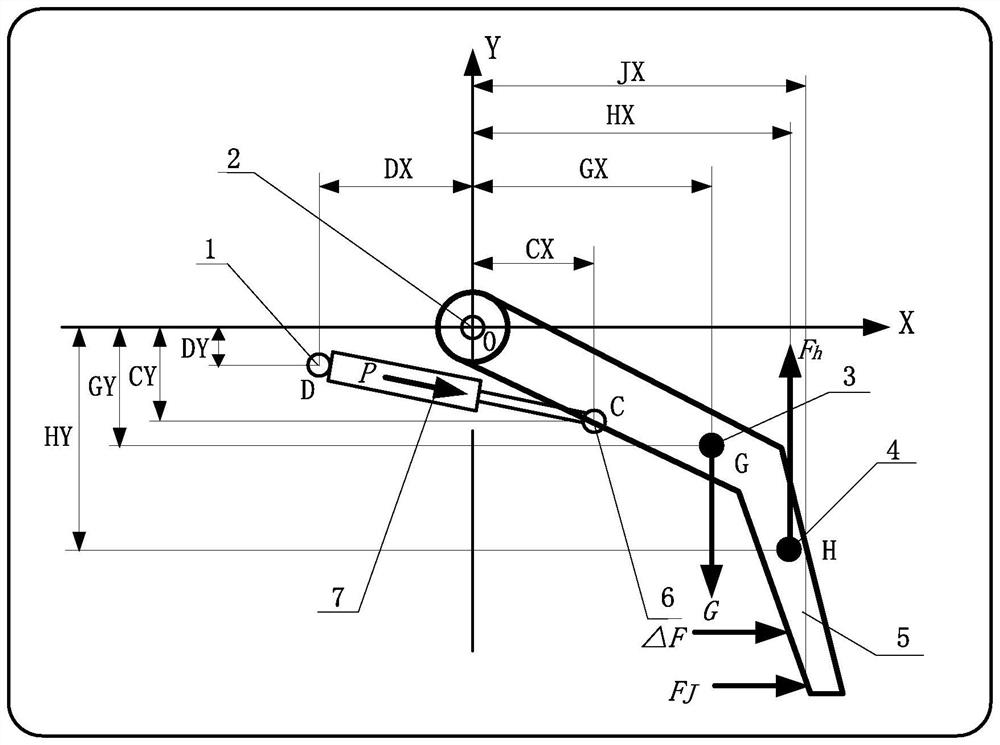

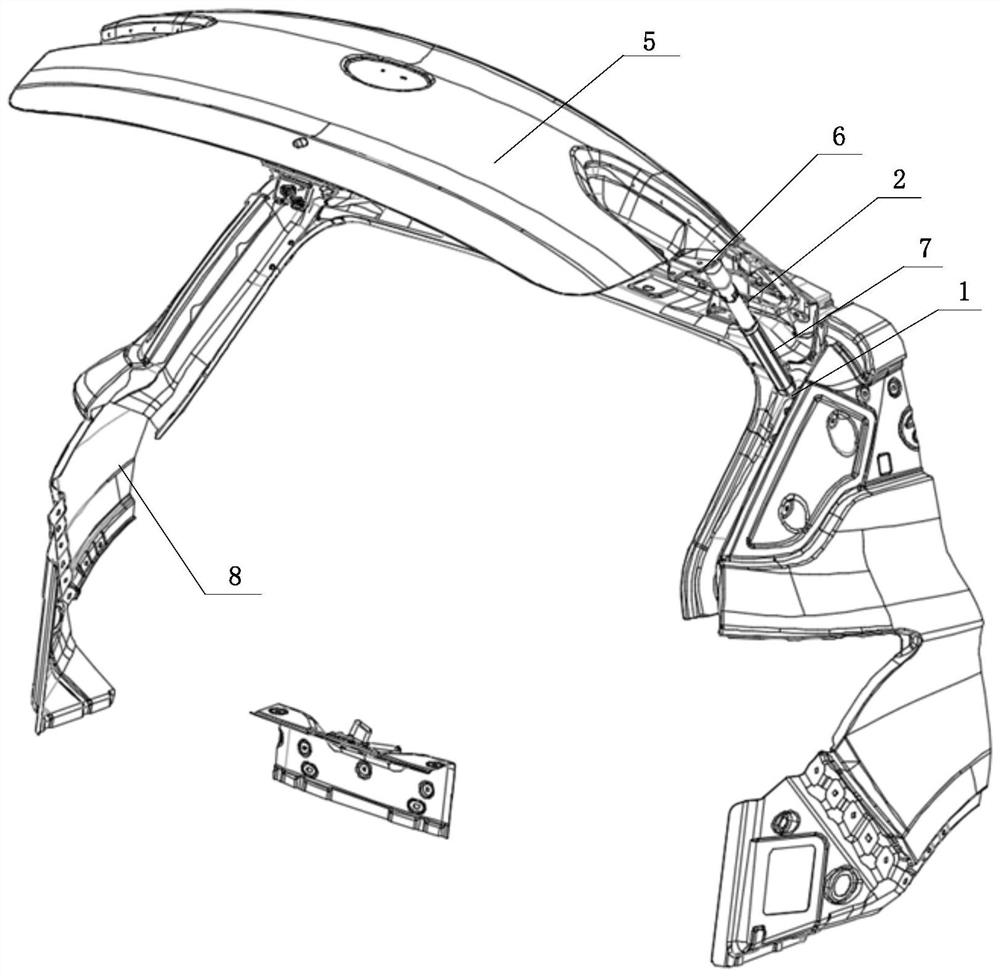

A simulation method and system for an automobile electric tailgate

ActiveCN107330155BSmall manual operation forceEasy to operateGeometric CADDesign optimisation/simulationKineticsKinematics

The invention discloses a simulation method and system of an automobile power tailgate. Based on the joint simulation design of kinematics and dynamics, model calculation is conducted with mechanical property parameters of the tailgate and external load parameters as input parameters, the fact that the tailgate hovers at any angle as a target function and the fact that manual operation force is minimized at the minimum relaxation rate of a spring as a constraint condition, and mechanical property output parameters meeting the model constraint condition are obtained. The input mechanical property parameters include tailgate parameters, motor parameters, screw parameters and / or reducer parameters, the external load parameters include manual operation force and anti-pinch force, and the output mechanical property parameters include parameters of a pole, parameters of the spring and installation positions of upper and lower spherical hinges on the pole.

Owner:佛山佑尔汽车智能技术有限公司

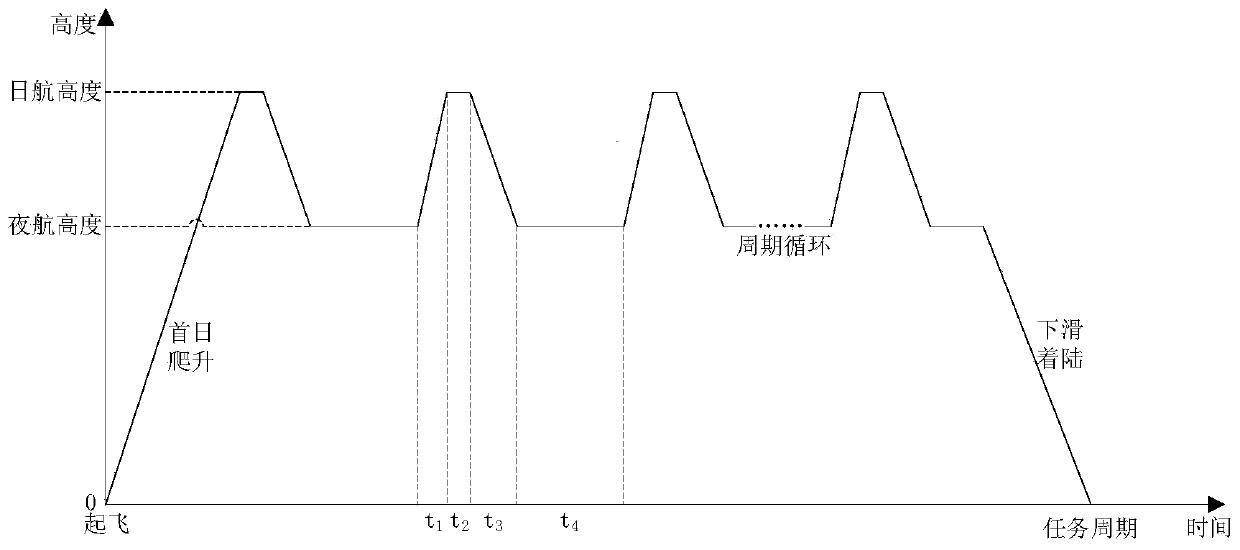

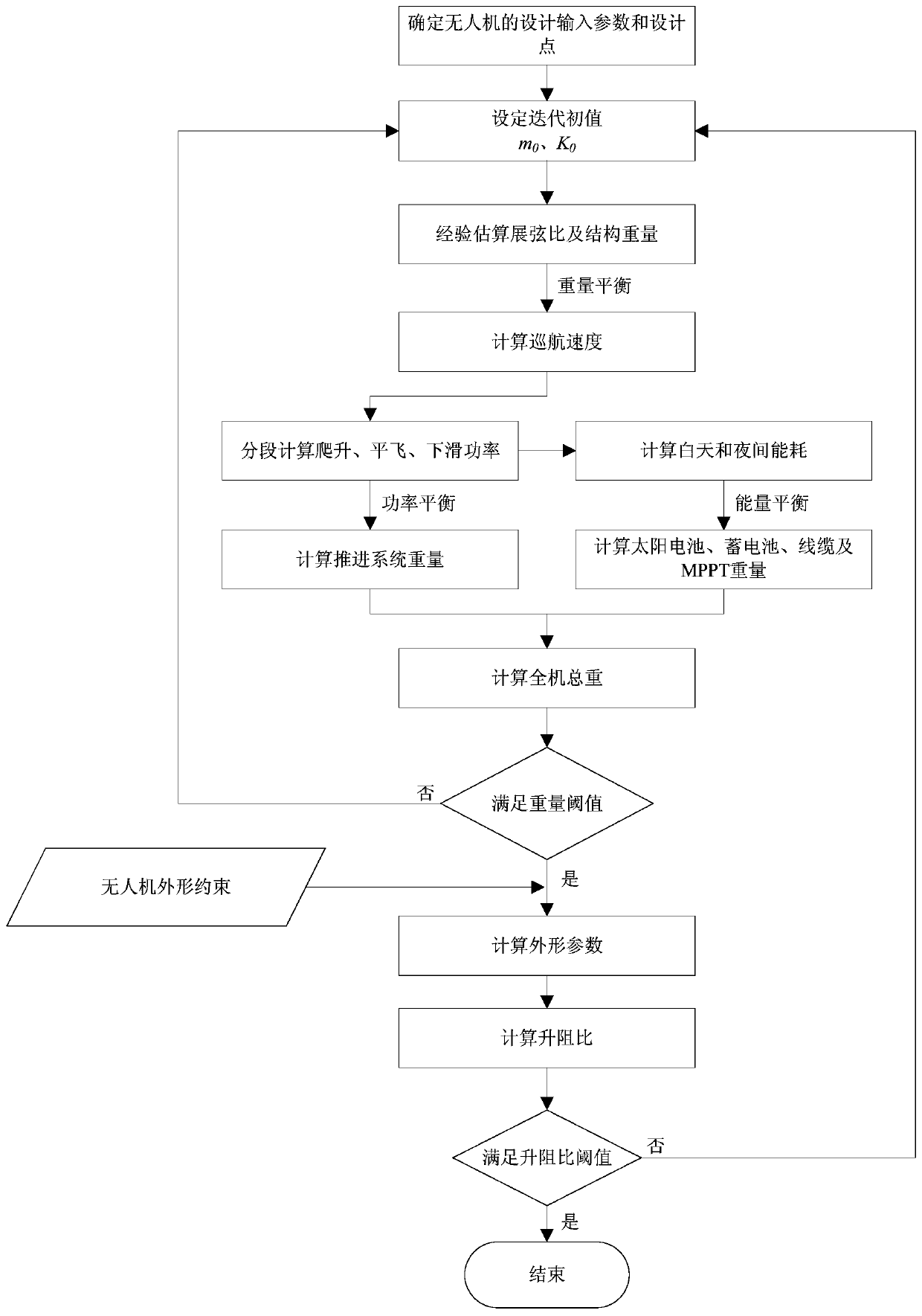

A method and system for determining overall parameters of a solar unmanned aerial vehicle

ActiveCN108216679BEfficient designMatch actual usage patternsGround installationsUncrewed vehicleSolar cell

The invention discloses a general parameter determination method and system for a solar unmanned aerial vehicle. The solar unmanned aerial vehicle adopts solar radiation as the unique energy source, and during a flight of the unmanned aerial vehicle, energy collection, energy consumption and energy storage are involved; moreover, since an unmanned aerial vehicle body, energy power and flight management are coupled with one another, a conventional design method and process for airplanes cannot be directly applied. According to the method, on the basis of a weight balance relation, a power balance relation and an energy balance relation of a point with the weakest solar energy in a flight profile, iterative computation is conducted on weight characteristics, aerodynamic characteristics and other main parameters, and general parameters of a primary scheme meeting tactical and technical index requirements can be obtained, wherein the general parameters mainly include the total weight of the unmanned aerial vehicle, the weight of a subsystem, a reference appearance, a lift-drag ratio, a solar cell laying rate, power characteristics matched with each kernel component of the whole systemand the like. The general parameter determination method for the solar unmanned aerial vehicle can be applied to primary general scheme design of this type of unmanned aerial vehicle.

Owner:CHINA ACAD OF AEROSPACE AERODYNAMICS

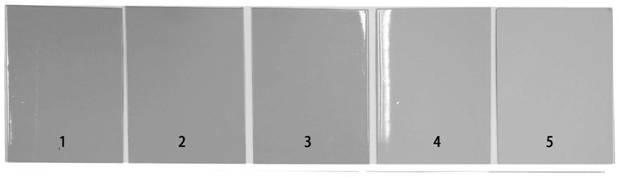

Design method of color sample of metallic glitter paint

ActiveCN113065565BImprove accuracyReduce dependenceColor measuring devicesCharacter and pattern recognitionMaterials scienceHuman eye

Owner:DONGFENG COMML VEHICLE CO LTD

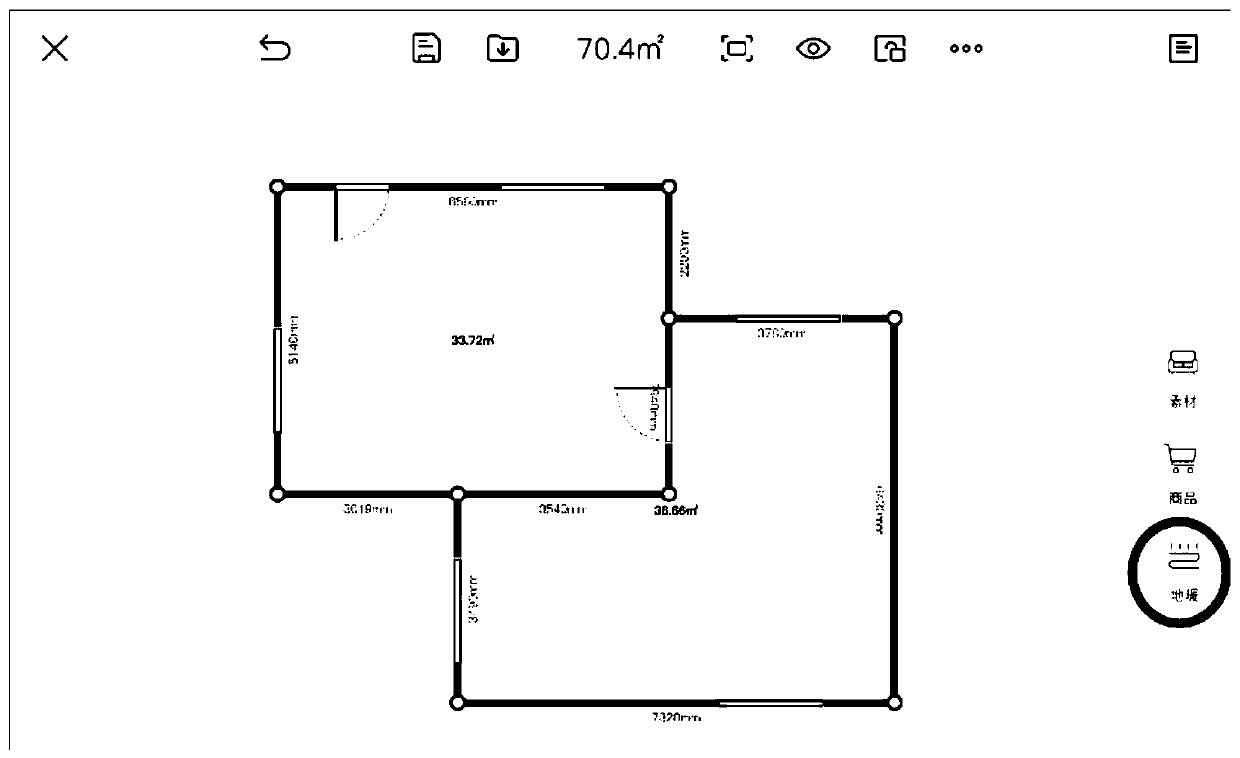

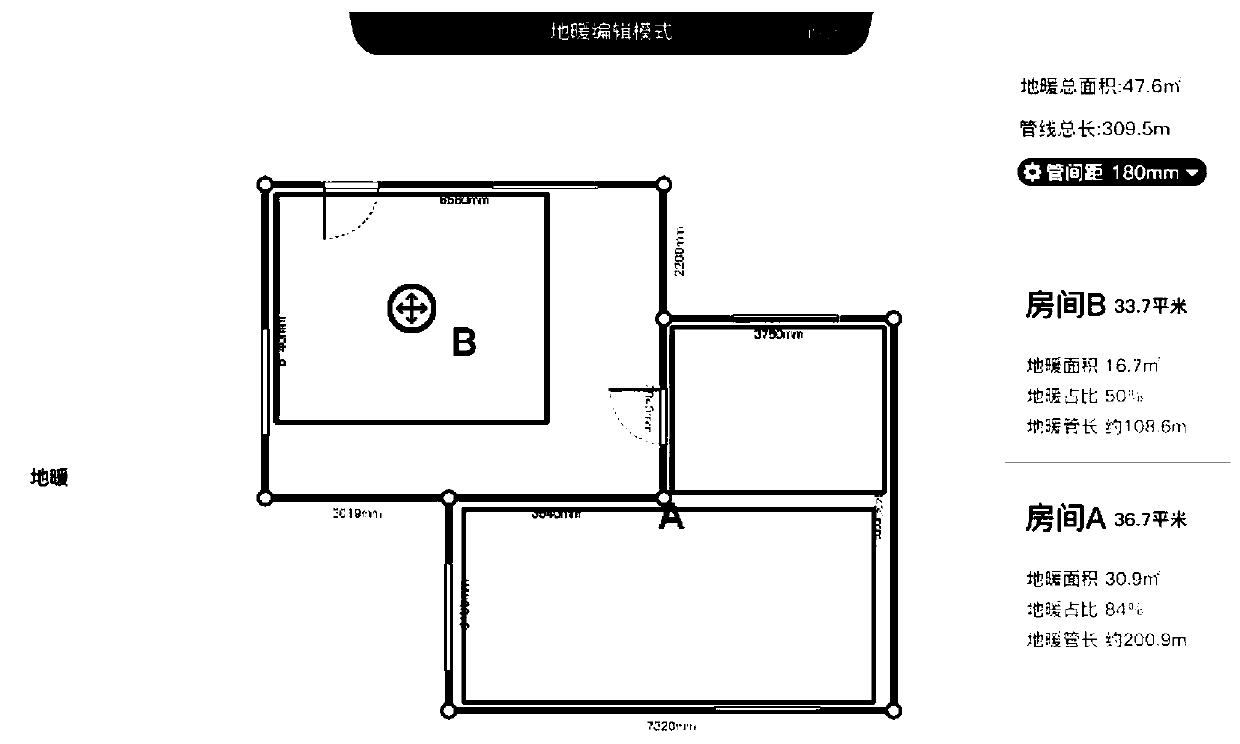

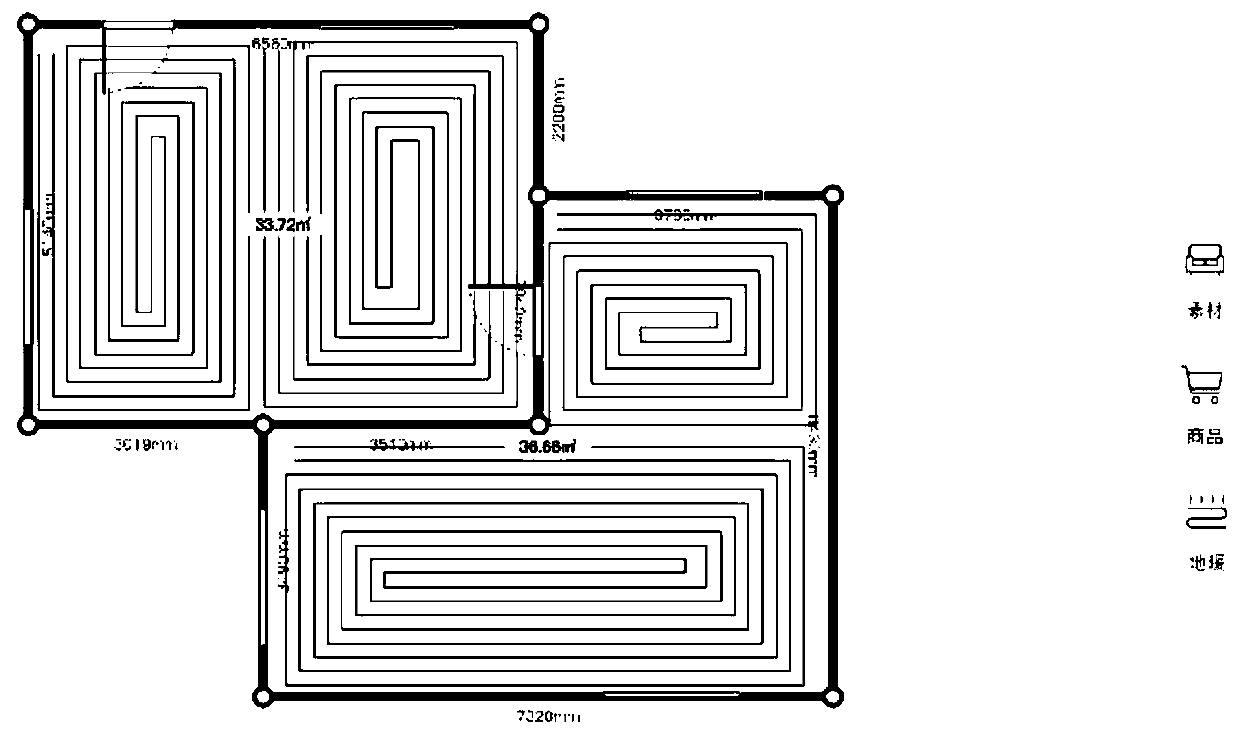

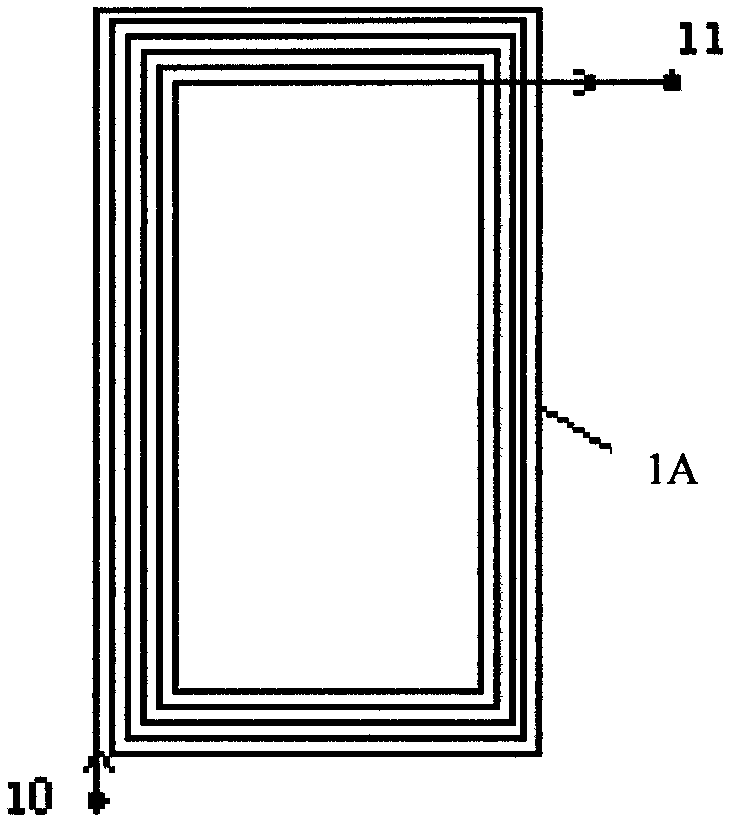

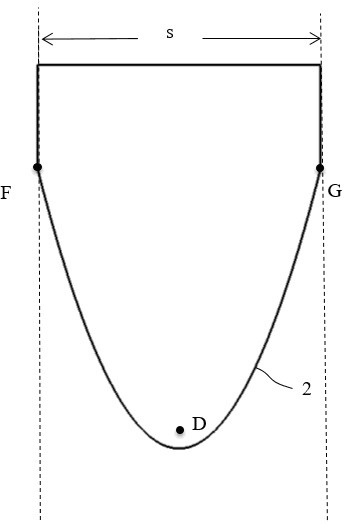

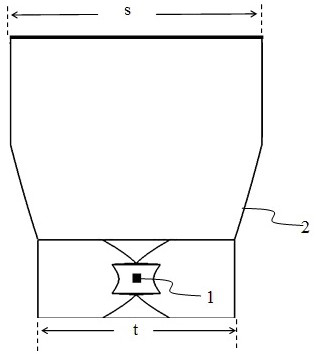

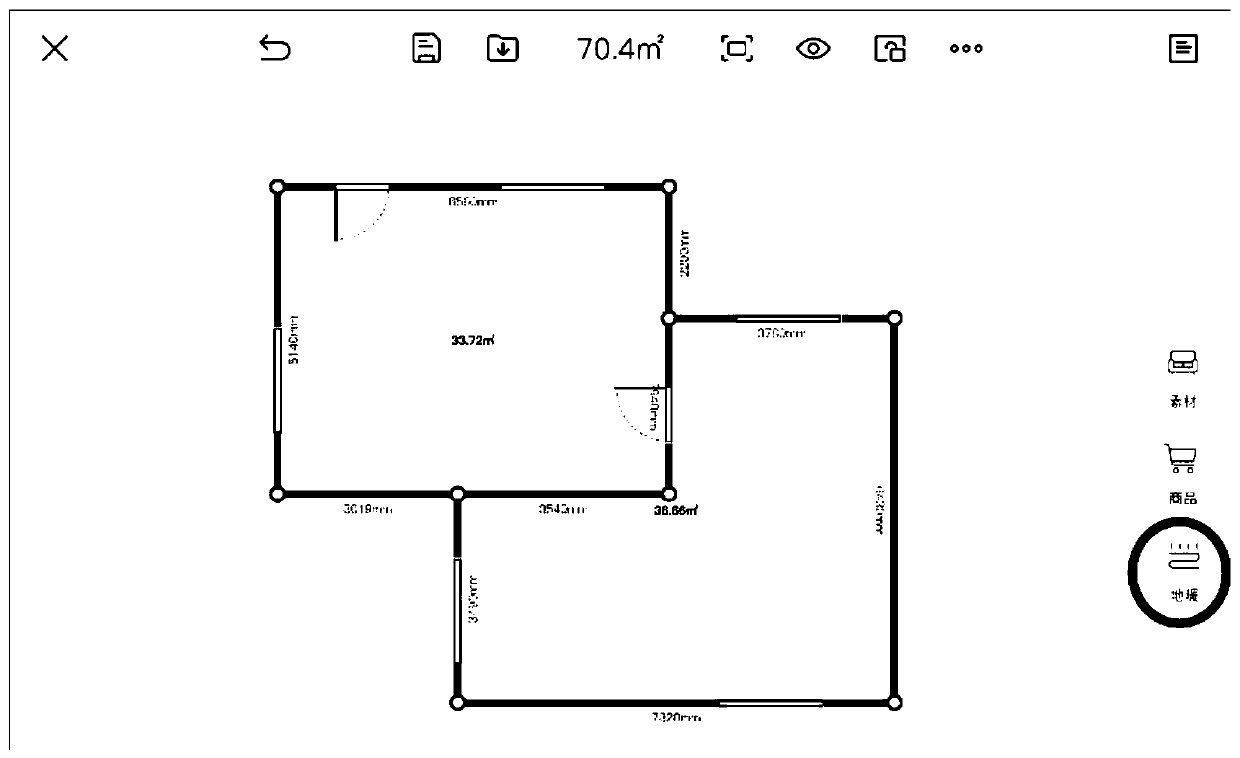

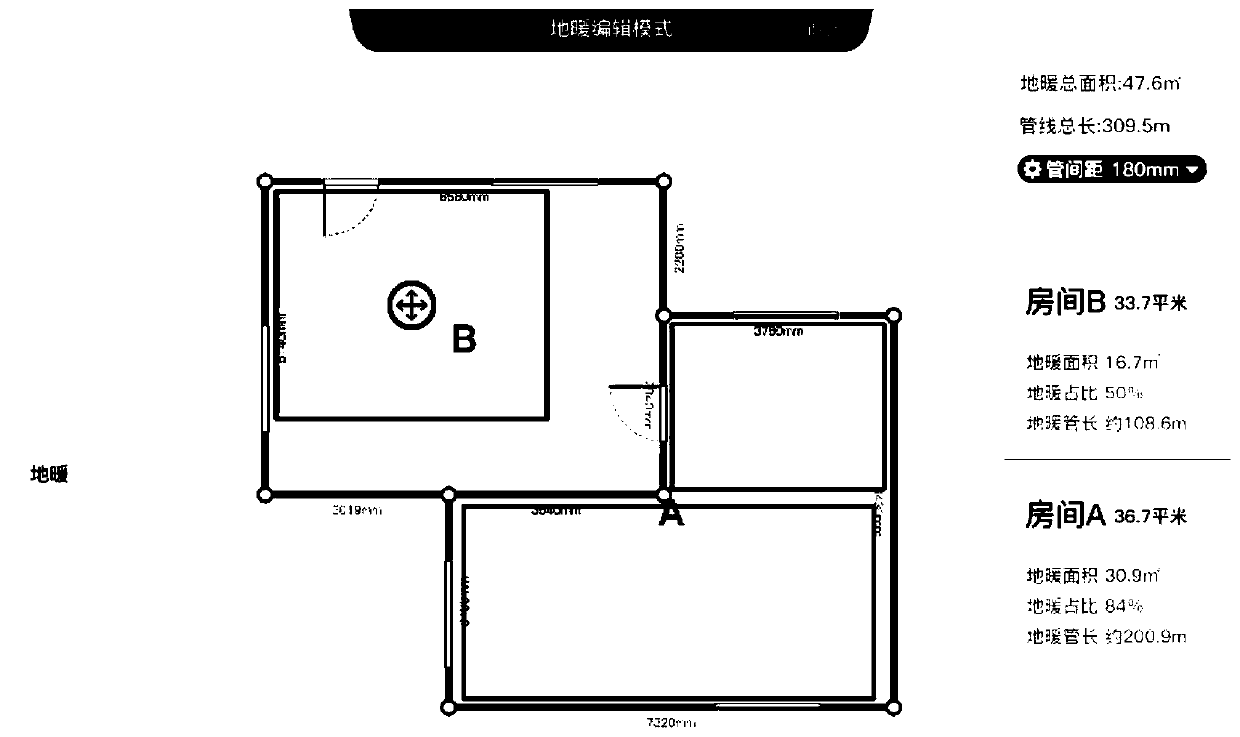

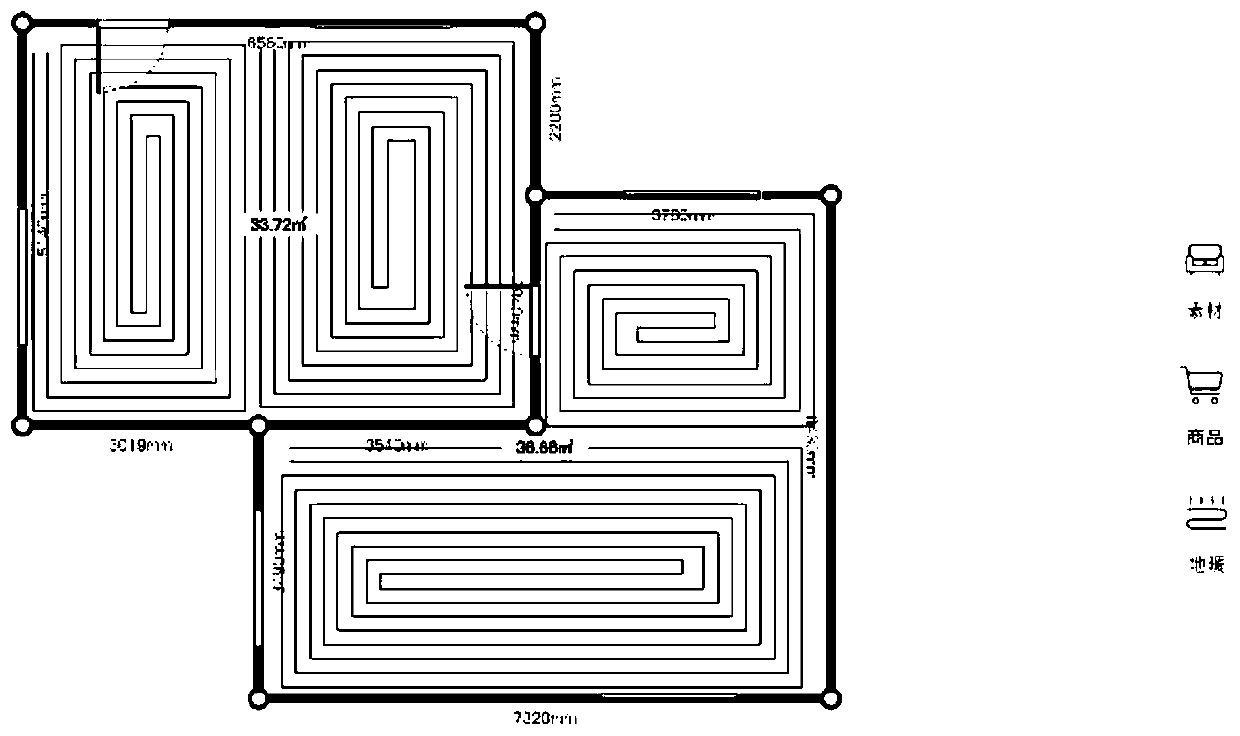

A design method for room floor heating pipeline

ActiveCN109344469BEasy to presentEasy to understandGeometric CADSpecial data processing applicationsDesign methodsService quality

The invention discloses a method for designing a room floor heating pipeline, which comprises the following steps: drawing a house type diagram of a room to be paved with floor heating, and obtaininga room area; Setting a floor heating construction area in the rendered room area; Set the distance between the ground heating pipes, and generate the ground heating wiring loop in the ground heating construction area. The method of the invention can intuitively and clearly show the design of the floor heating pipeline to the user, and improve the communication efficiency and the service quality before sale. At the same time, it is convenient to guide the construction work, reduce the construction errors caused by reading construction drawings, and improve the construction efficiency.

Owner:江苏橙智云信息技术有限公司

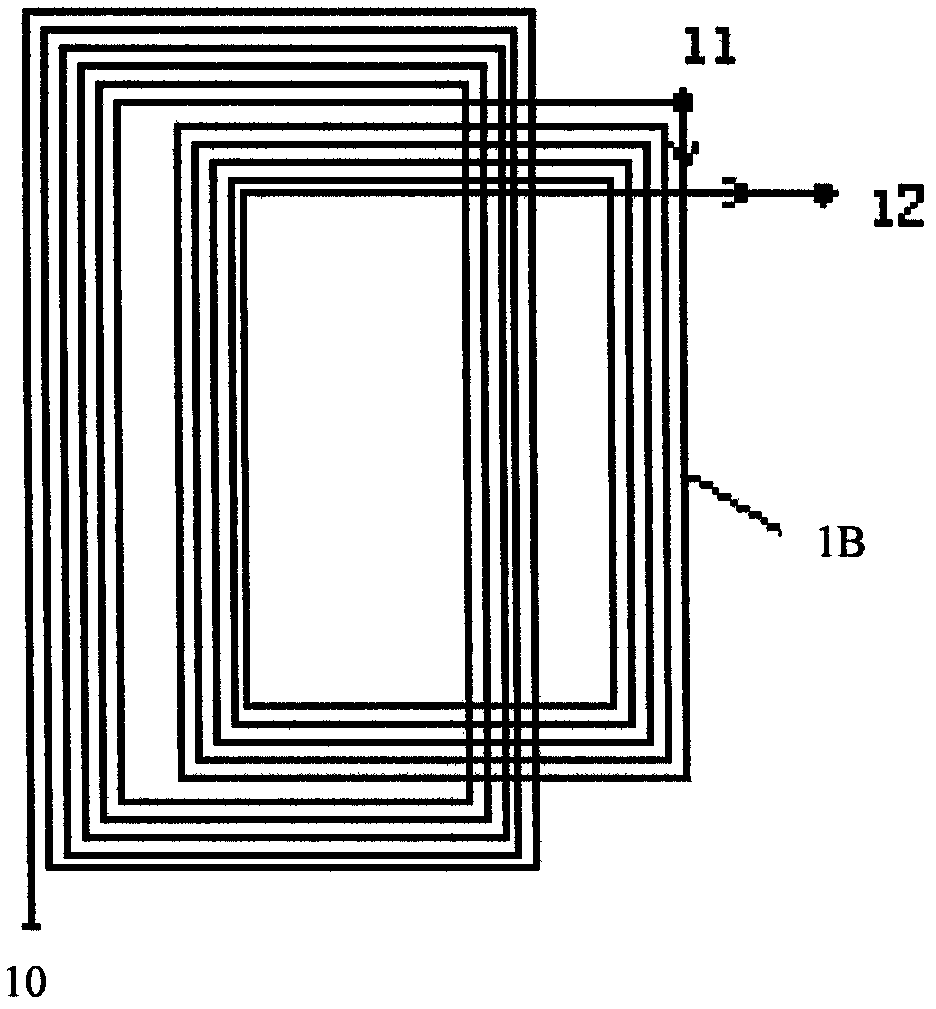

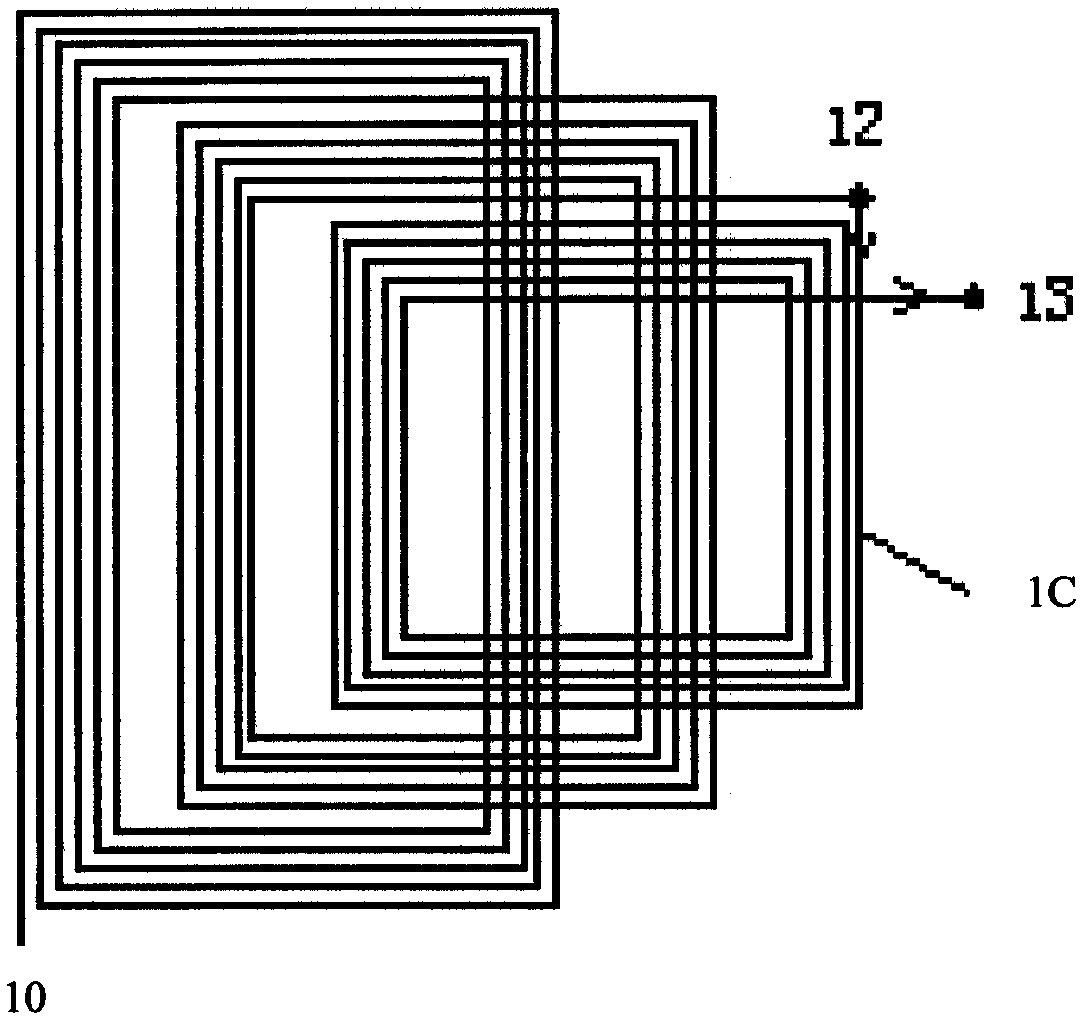

Integrated coil assembly with diversifying three-phase coils and method for manufacturing integrated coil assembly

InactiveCN102185402AReduce weightImprove efficiencyManufacturing dynamo-electric machinesWindings conductor shape/form/constructionThree-phaseEngineering

The invention relates to an integrated coil assembly with diversifying three-phase coils and a method for manufacturing the integrated coil. The integrated coil assembly comprises a first coil assembly, a second coil assembly, a third coil assembly and a fourth coil assembly; each coil assembly comprises a large-size coil loop, a medium-size coil loop and a small-size coil loop; the first coil assembly, the second coil assembly, the third coil assembly and the fourth coil assembly are mutually arranged in series; the large-size coil loop, the medium-size coil loop and the small-size coil loop of the first coil assembly are respectively and correspondingly connected to the small-size coil loop, the medium-size coil loop and the large-size coil loop of the second coil assembly; the small-size coil loop, the medium-size coil loop and the large-size coil loop of the second coil assembly are respectively and correspondingly connected to the large-size coil loop, the medium-size coil loop and the small-size coil loop of the third coil assembly; and the large-size coil loop, the medium-size coil loop and the small-size coil loop of the third coil assembly are respectively and correspondingly connected to the small-size coil loop, the medium-size coil loop and the large-size coil loop of the fourth coil assembly. By the integrated coil assembly, coils are compact at the two coil ends to save space, reduce the cost and the overall weight of the coil assembly and improve the motor efficiency. Moreover, the heat dispersion performance is improved to facilitate uniform distribution of heat.

Owner:AKRIBIS SYST SHANGHAI

A Design Method of Optical System of Thick-walled Parts Containing Diffusion Holes Eliminating Dark Areas at Chamfers

The invention provides a method for designing the optical system of the thick-walled part including the diffusion hole that eliminates the dark area at the chamfer, by changing the collimation hole of the existing thick-walled part into a diffusion hole, or changing the collimation surface into a diffusion hole On the surface, through the diffused hole and the effect of scattering light on the diffused surface, the area of the dark area caused by the chamfering of the original collimation hole is covered by the light scattered by the diffused hole, and the coverage of the dark area is passed through It is obtained from the precise calculation of the previous design, so it can well improve and solve the problems of dark areas and unevenness in conventional optical structures. Through the combination of theory and simulation fine-tuning in the early stage, the design result is more accurate, and there is no need for additional design or process adjustment in the later stage, and the feasibility of the mold will be greatly improved; the final optical effect will also be more controllable and uniform.

Owner:MAGNETI MARELLI AUTOMOTIVE COMPONENTS WUHU

Design method of thick-wall part optical system comprising diffusion hole for eliminating dark area at chamfer

ActiveCN111999887AHigh feasibilityAccurate design resultsOptical elementsScattering effectThick wall

The invention provides a design method of a thick-wall part optical system comprising a diffusion hole for eliminating a dark area at a chamfer. According to the design method, a collimation hole of an existing thick-wall part is changed into a diffusion hole, or a collimation surface is changed into a diffusion surface; by means of the scattering effect of the diffusion hole and the diffusion surface on light, the area, caused by chamfering, of a dark area of the original collimation hole is covered with the light scattered by the diffusion hole, the coverage of the dark area is obtained through accurate calculation of earlier-stage design, and therefore the problems of the dark area and non-uniformity of a conventional optical structure can be well improved and solved. Through the designof combining the primary theory and simulation fine adjustment in the earlier stage, the design result is more accurate, additional design or process adjustment in the later stage is not needed, andthe mold feasibility is further greatly improved; and the final optical effect is more controllable and more uniform.

Owner:MAGNETI MARELLI AUTOMOTIVE COMPONENTS WUHU

A room floor heating pipeline design system

ActiveCN109063382BEasy to presentEasy to understandGeometric CADDesign optimisation/simulationComputer moduleData acquisition

The invention discloses a room floor heating pipeline design system, which comprises a drawing module for drawing the room area; a data acquisition module for acquiring spatial information of the roomarea, information on the construction area of ground heating, set floor heating pipe spacing; a data processing module: wherein according to the data of the data acquisition module, a ground heatingwiring loop is generated in the ground heating construction area. The system of the invention can intuitively and clearly show the design of the floor heating pipeline to the user, and improve the communication efficiency and the service quality before sale. At the same time, it is convenient to guide the construction work, reduce the construction errors caused by reading construction drawings, and improve the construction efficiency.

Owner:江苏橙智云信息技术有限公司

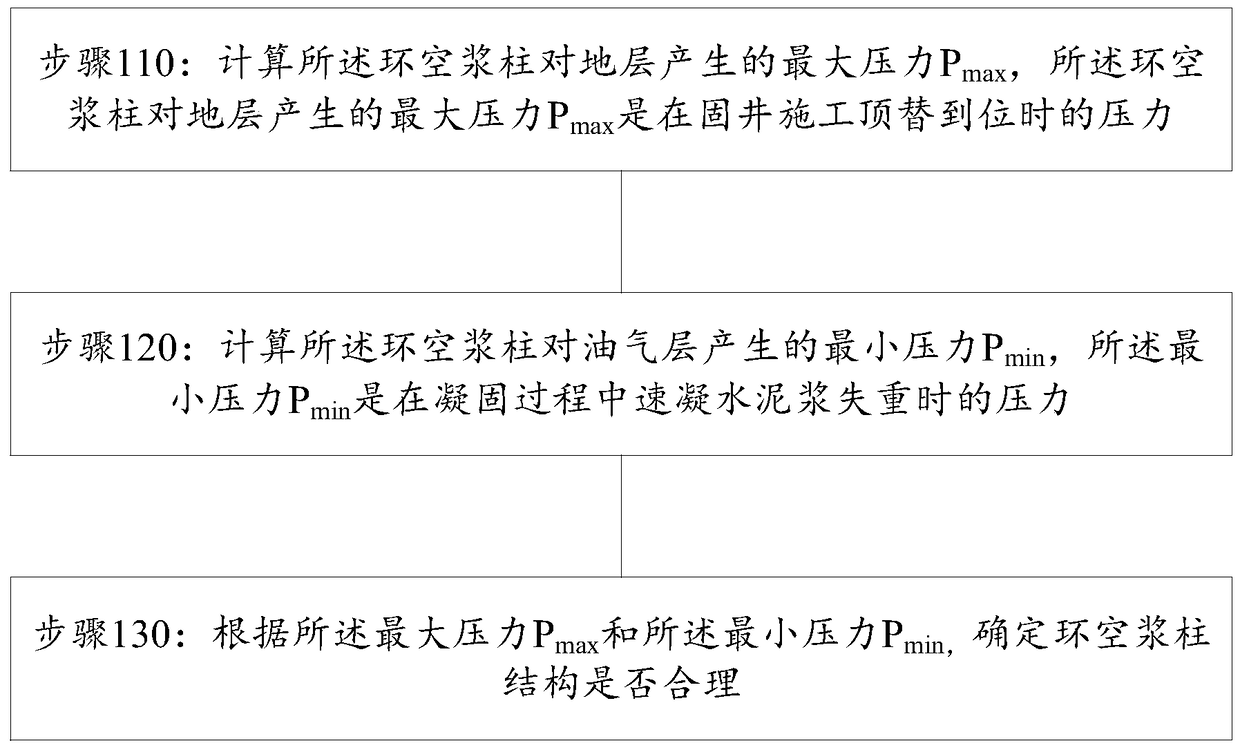

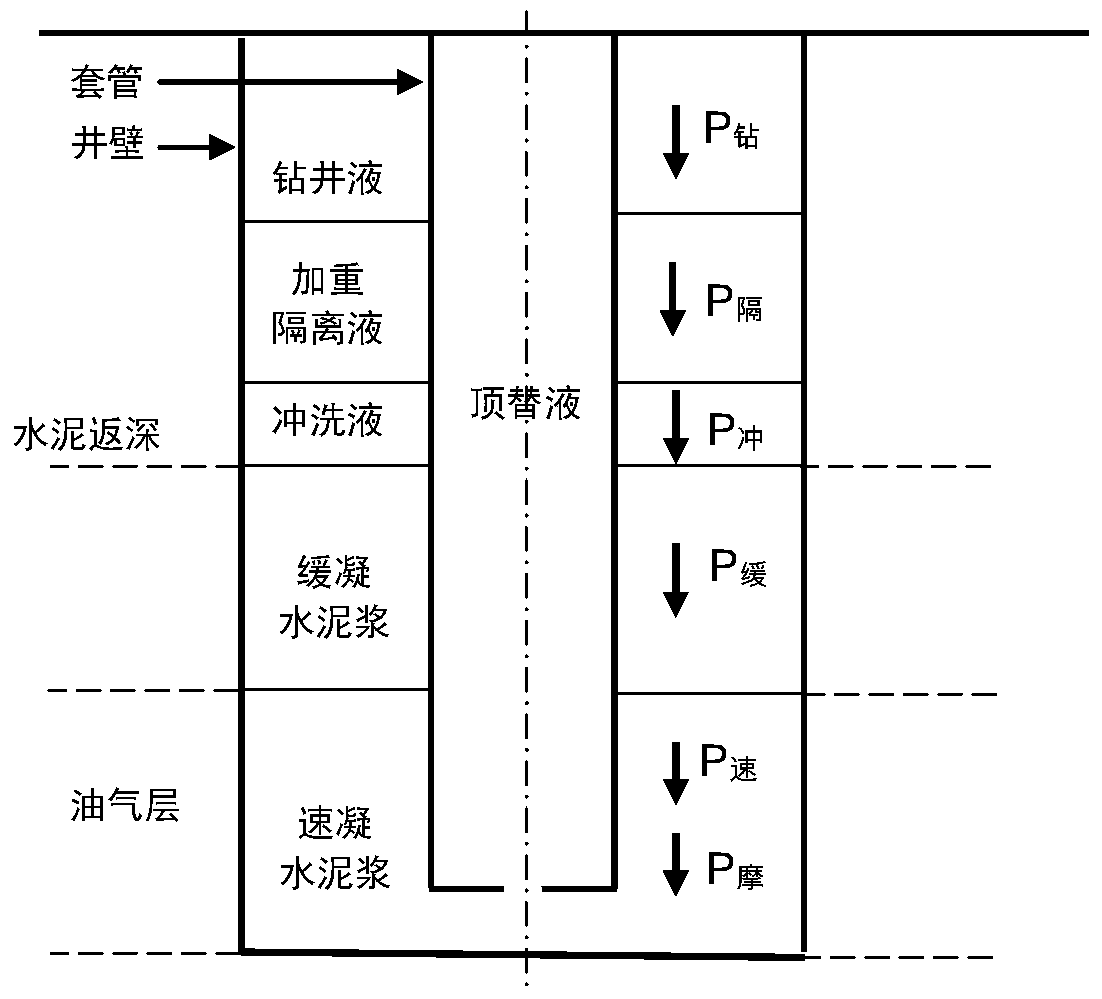

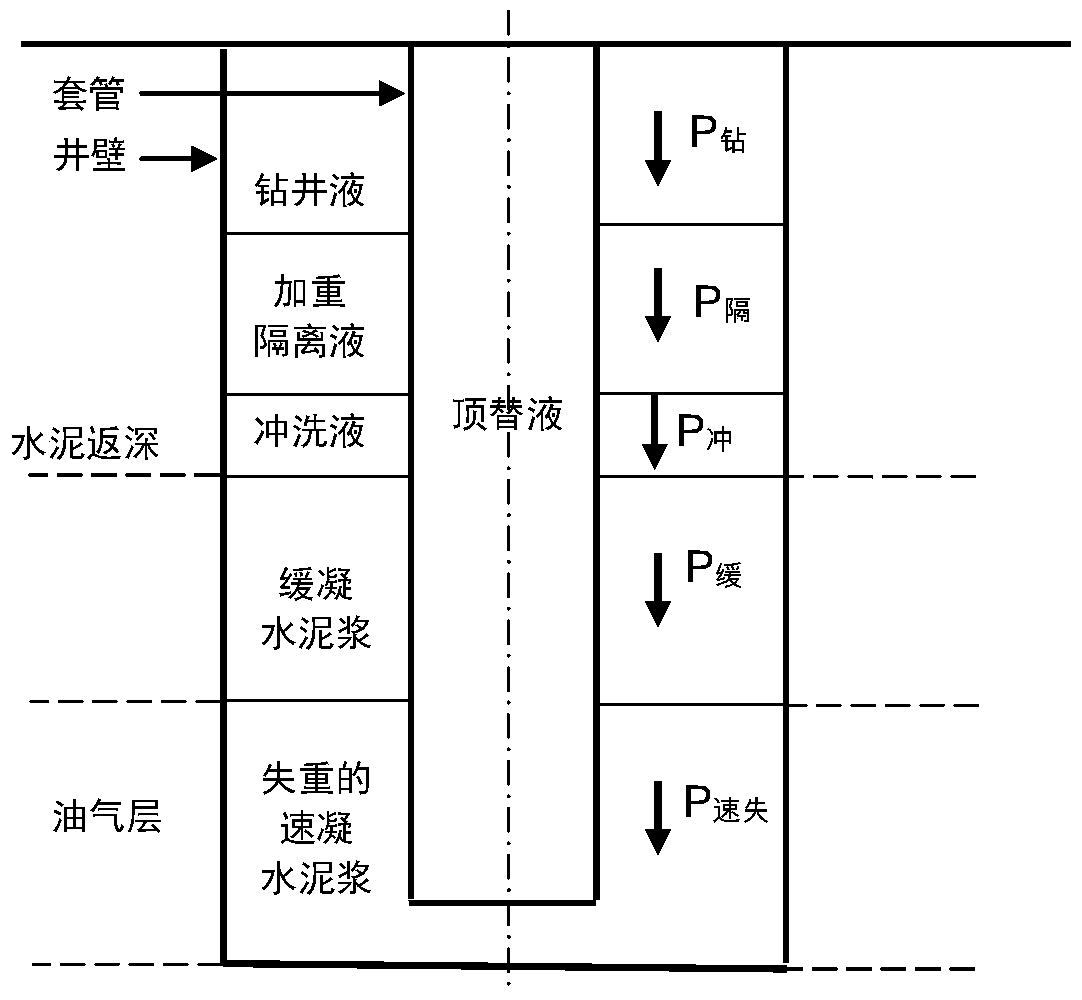

A Design Method for Cementing Annulus Slurry Column Structure

ActiveCN105298440BAvoid pressure leakageScientific and reasonable design methodSealing/packingStructure of the EarthWell cementing

The invention discloses a design method of a well cementation annulus slurry column structure. The design method comprises following steps: calculating the maximum pressure Pmax applied on the stratum by an annulus slurry column, wherein the maximum pressure Pmax is the pressure generated when the slurry is displaced in place during the well cementation construction; calculating the minimum pressure Pmin applied on an oil gas bed by the annulus slurry column, wherein the minimum pressure Pmin is the pressure generated when the rapidly cemented cement slurry loses weight during a cementing process; and determining whether the annulus slurry column structure is reasonable according to the maximum pressure Pmax and the minimum pressure Pmin. According to the design method, various pressures related to the annulus slurry column structure can be quantitatively calculated and contrasted, and the determined slurry column structure can stably press the oil gas bed and can prevent the leakage of the stratum. The design method is more scientific and reasonable.

Owner:PETROCHINA CO LTD

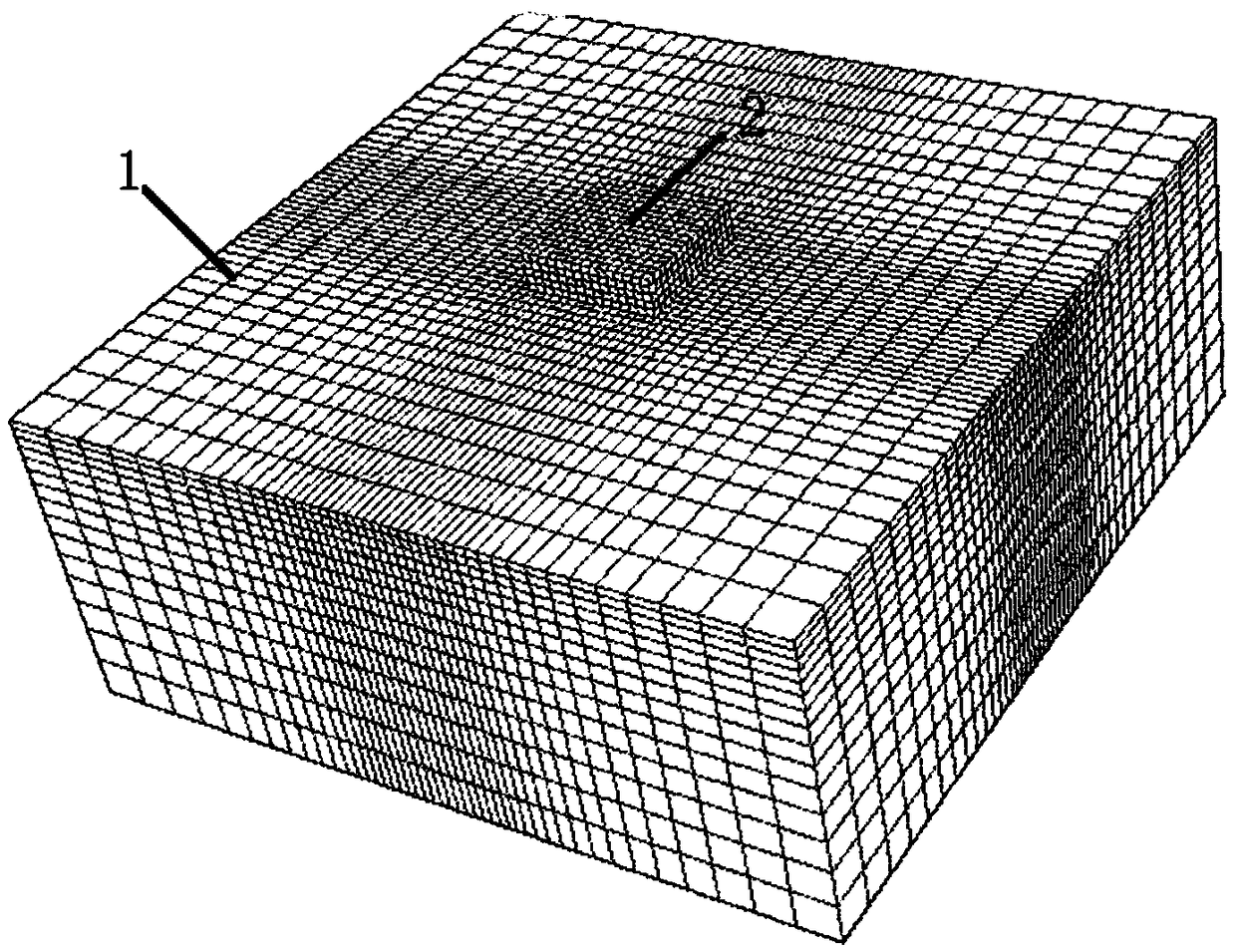

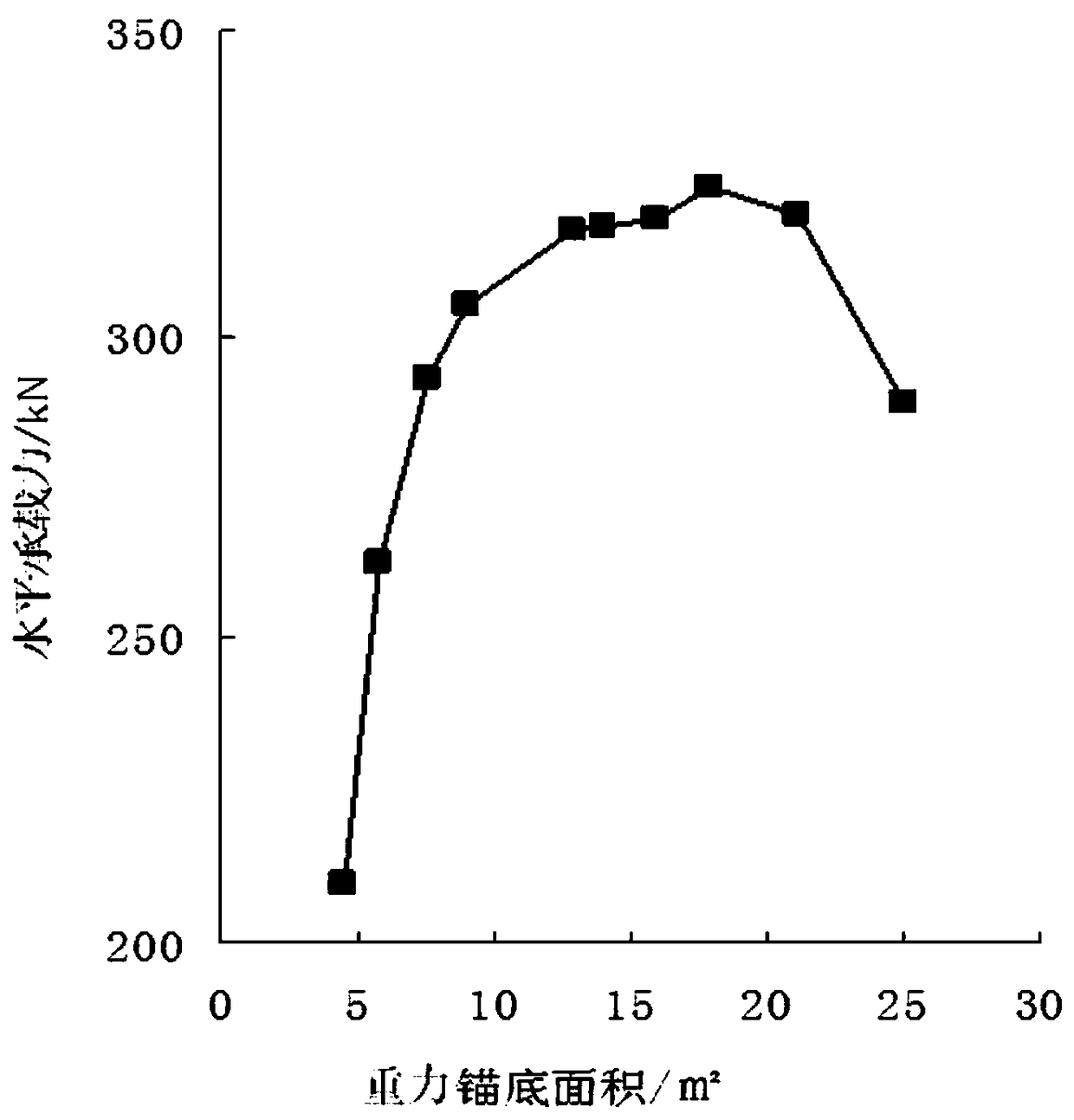

Optimal Calculation Method for Design of Gravity Anchor on Calcareous Rock and Soil

InactiveCN106759328BPredicted Horizontal Bearing CapacityEnsure safety and stabilityArtificial islandsUnderwater structuresCalcium in biologyElement model

Owner:TIANJIN UNIV

New Design Method of DC Inductor of Current Source Converter

The invention provides a novel design method for direct-current inductance of a current source converter. The method comprises the following steps: 1, calculating parameters of a system, comprising a converter alternating-voltage amplitude value Vtm, a converter alternating-current phase-A voltage initial phase gamma, a modulation ratio m and a reference current angular displacement initial value theta 0; 2, calculating the maximum value of a volt-second constant according to volt-second balance principles; 3, considering influences of different modulation methods for ripples, finding possible maximum volt-second constants, and taking the maximum value in the possible maximum volt-second constants as C; 4, calculating the direct-current inductance. The novel design method for the direct-current inductance of the current source converter disclosed by the invention overall considers influences of various factors, and design results are very accurate; compared with the traditional design method, the design value of the direct-current inductance can be greatly reduced under same design requirements of the direct-current current ripples to greatly reduce the cost and the size of the direct-current inductance.

Owner:上海中绿新能源科技有限公司

Radiation Performance Analysis Method of High Resolution SAR Satellite

ActiveCN106353777BAccurately image echo signal energyFully reflect space variabilitySatellite radio beaconingSystems designSynthetic aperture radar

The invention relates to a method for analyzing radiation properties of high-resolution SAR (synthetic aperture radar) satellites, and belongs to the technical field of overall designs of SAR satellites. The method has the advantages that radiation property indexes of various satellite-borne SAR working modes are accurately computed, and system design results are inspected and rechecked for the high-resolution SAR satellites and the high-resolution SAR satellites in variable-repetition-frequency modes in particular; echo signal energy starts to be computed point by point along imaging time from single-pulse radar equations, accordingly, time-dependent variation conditions of antenna gain, ground-object back-scattering coefficients, slope distances and radar scattering areas of the SAR satellites can be sufficiently reflected, accurate imaging echo signal energy can be obtained, and the accurate radiation property indexes of the high-resolution SAR satellites further can be obtained.

Owner:BEIJING INST OF SPACECRAFT SYST ENG

Electromagnetic Design Method of Surface-mounted Permanent Magnet Motor

ActiveCN112713729BImprove accuracyTo overcome inaccurate coefficients and other deficienciesManufacturing stator/rotor bodiesSurface mountingMagnetic poles

The invention discloses an electromagnetic design method of a surface-mounted permanent magnet motor, which includes a brief magnetic circuit design and electromagnetic field finite element calculation of the permanent magnet motor. The brief magnetic circuit design is mainly based on the technical requirements of the motor as input, according to the The basic formula of electromagnetic design, which determines the size contained in the stator core of the permanent magnet motor and the preliminary size of the rotor pole; the finite element calculation of the electromagnetic field includes static magnetic field calculation and transient magnetic field calculation, and the static magnetic field calculation is used to determine The radial dimension of the rotor poles, the transient magnetic field calculation described is used to determine the axial length of the motor. The method involved in the invention is not limited by the size of the permanent magnet motor, and overcomes the inaccurate coefficients in the empirical formula of the traditional motor design and calculation process. At the same time, the invention considers the saturation characteristics of the motor in the calculation, and improves the accuracy of the calculation results. It is especially suitable for the design analysis of surface-mounted permanent magnet motors.

Owner:WUHAN MARINE ELECTRIC PROPULSION RES INST CHINA SHIPBUILDING IND CORP NO 712 INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com