A method for optimal design of parabolic-arc-shaped head structure

An optimization design, parabolic technology, applied in design optimization/simulation, geometric CAD, special data processing applications, etc., can solve problems such as huge impact on pressure performance, inability to obtain structures, and difficulty in manufacturing, to improve mechanical properties, design Accurate results and improved ultimate load effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

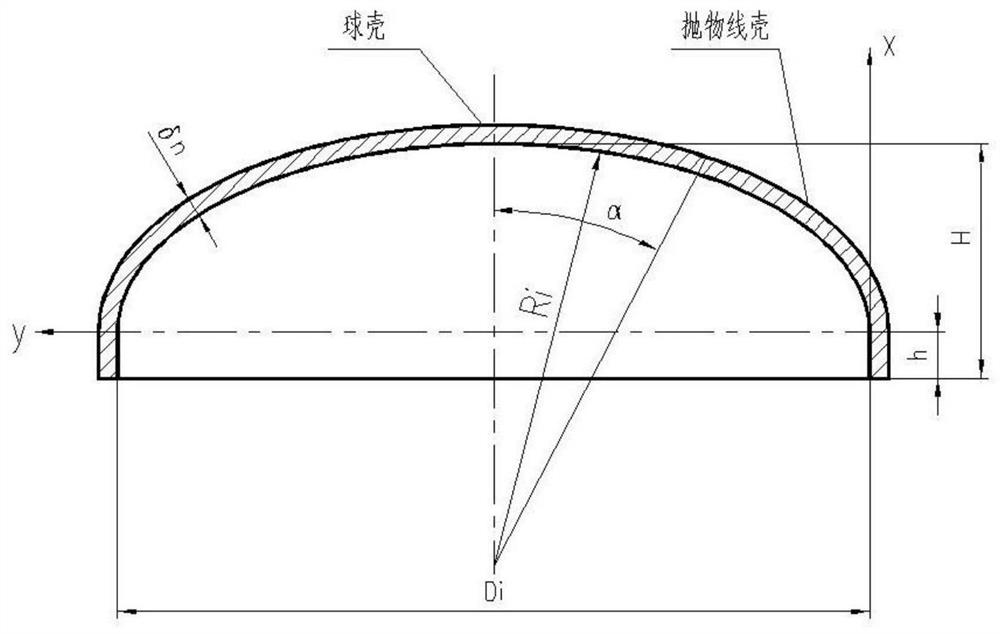

[0017] In order to make the technical means, creative features, goals and effects realized by the present invention easy to understand, the following embodiments of the accompanying drawings will specifically describe the parabolic-arc-shaped head structure optimization design method of the present invention.

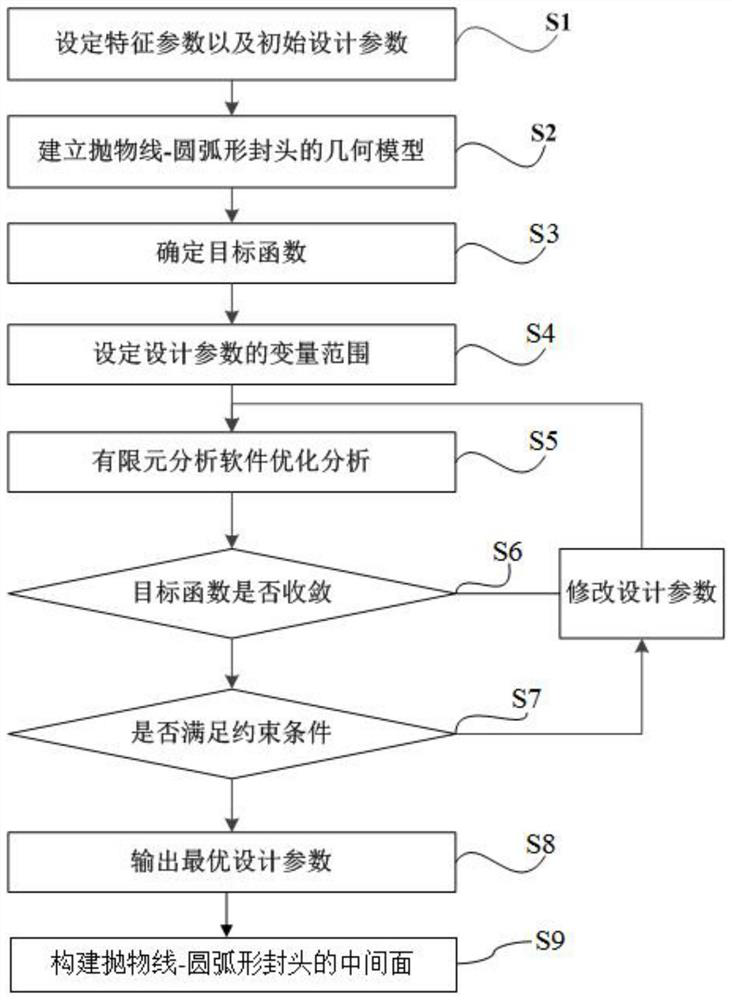

[0018] figure 1 It is a flow chart of the method for optimizing the design of the parabolic-arc-shaped head structure in the embodiment of the present invention.

[0019] like figure 1 As shown, the flow of the parabolic-circular arc head structure optimization design method includes the following steps:

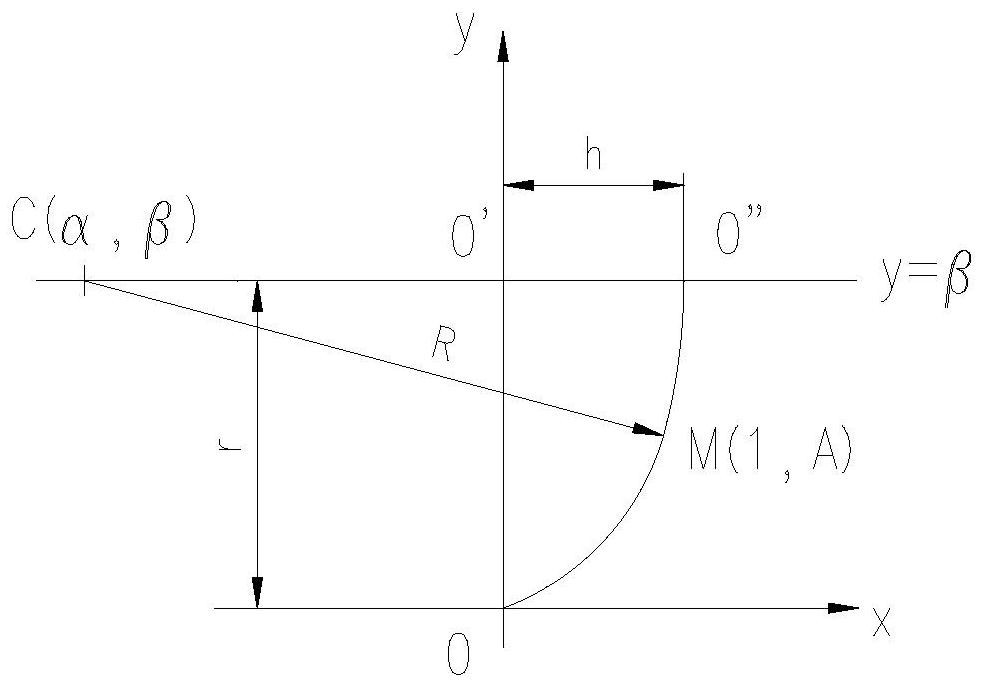

[0020] Step 1: Set the characteristic parameters and initial design parameters of the parabolic-arc-shaped head, the characteristic parameters are the geometric dimensions of the cylinder, and the initial design parameters are the coordinates of the center of curvature and the radius of curvature of the parabolic-arc-shaped head. In this embodiment, the material of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com