Robot station design method applied to welding assembly line

A design method and robot technology, applied in welding equipment, auxiliary welding equipment, metal processing equipment, etc., to achieve the effect of reasonable design, reasonable conception, flexible and efficient production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

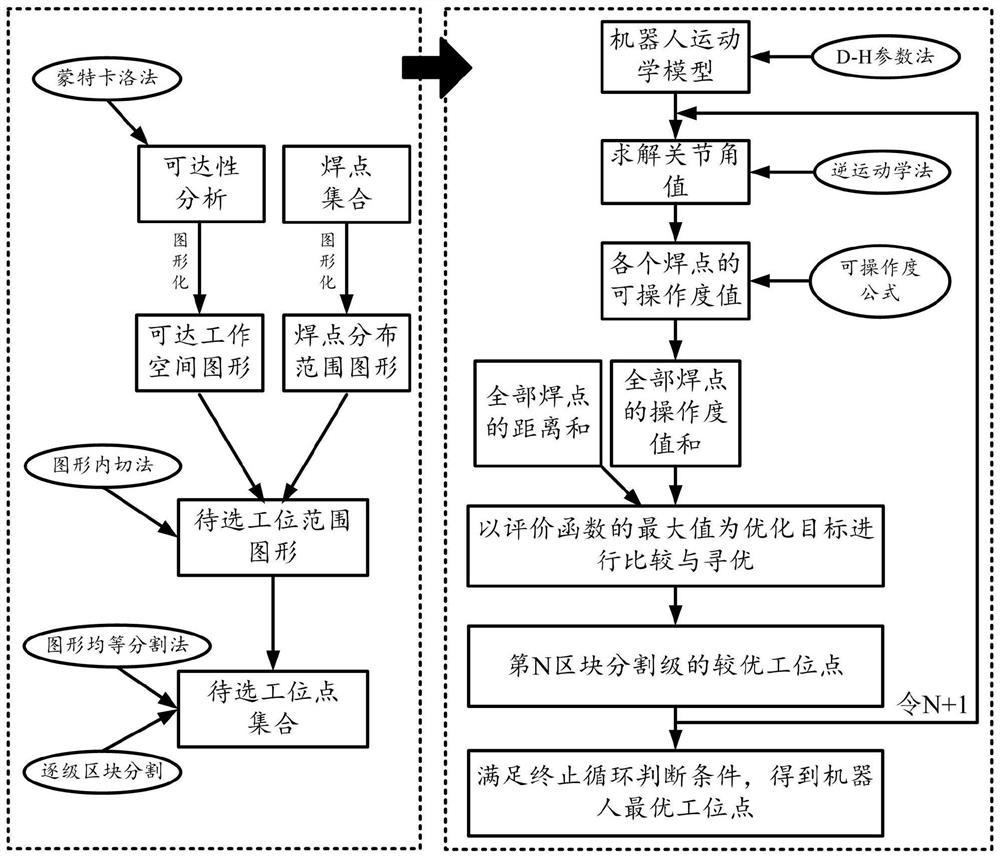

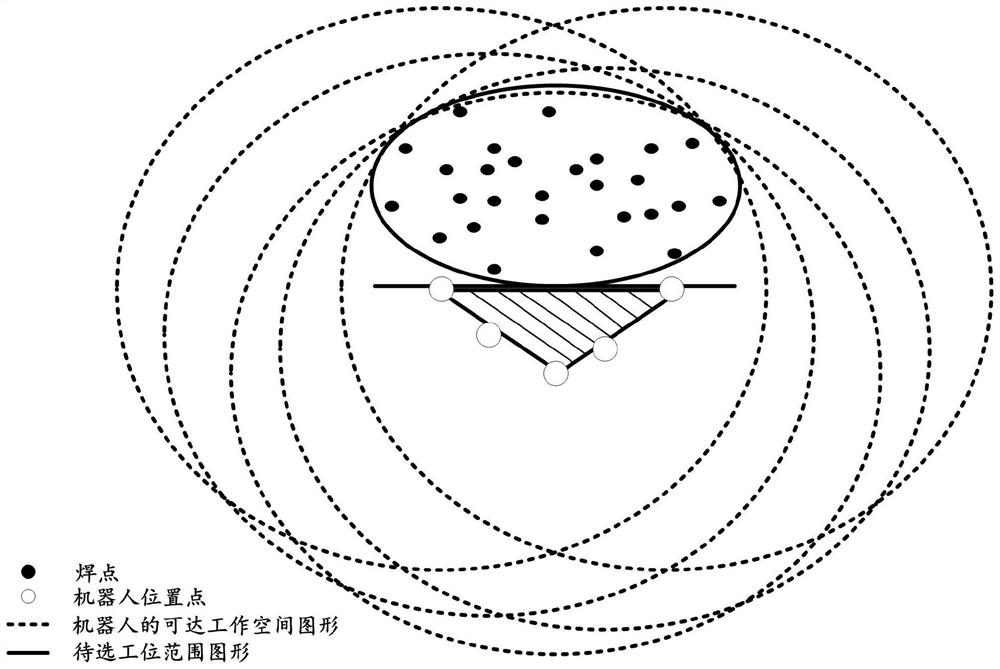

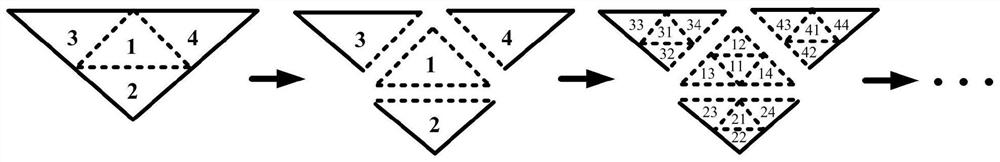

[0019] The invention provides a robot station design method applied to a welding line, which solves the problems of long time-consuming welding movement posture and high energy consumption existing in the placement of traditional robot stations. It should be emphasized that the robot station design method applied to welding lines proposed by the present invention is not only applicable to automobile welding lines, but also applicable to welding lines of other products. The basic content of the design method of the present invention is: at first, determine the reachable work space figure of welding point distribution range figure and robot; The set of station points to be selected is obtained by segmenting blocks step by step; finally, the optimal station point selection is realized by using the evaluation function based on the operability index and the distance index, and the station design of the welding robot is completed. The technical solutions of the present invention wil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com