CAD and WebGl based deepen design method of fabricated construction prefabricated columns and laminated beams

A technology of in-depth design and prefabricated columns, applied in truss structures, geometric CAD, structural elements, etc., can solve problems such as greater impact on design quality and unfavorable industrial production, and achieve information sharing, accurate design results, and maximized collaboration The effect of the design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

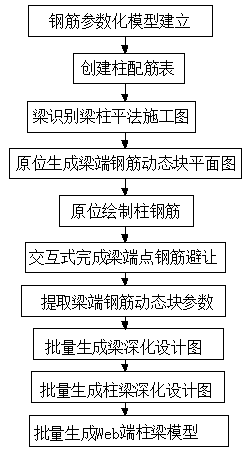

[0068] Such as figure 1 As shown, the implementation example of the present invention provides a kind of prefabricated structure based on CAD and WebGl and composite beam deepening design method, this method is divided into

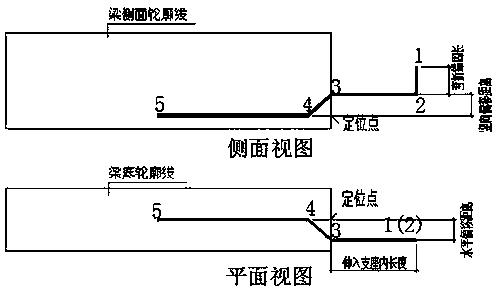

[0069] Step 1: Create in the CAD platform such as figure 2 The parametric model of the dynamic block of the longitudinal reinforcement at 5 nodes is shown, and the change of the anchorage length of the reinforcement, the operation of the horizontal offset of the reinforcement, the operation of the vertical offset and the adjustment of the bending length can be realized through the parameter value;

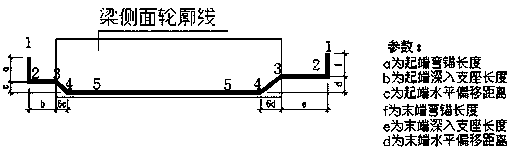

[0070] Create CAD-based platforms such as image 3 The 10-node parametric model of the longitudinal reinforcement shown in the figure can realize the change of the anchorage length at both ends of the longitudinal reinforcement, horizontal offset operation, vertical offset operation and bending length adjustment operation of the longitudinal reinforcement th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com