Prefabricated reinforced concrete structural column for prefabricated buildings

A technology of reinforced concrete for construction, applied in the direction of building structure, building, column, etc., can solve the problems of uncontinuous assembly, hidden quality, poor vibration resistance, etc., achieve industrialization of construction, continuous and fast construction, and improve seismic performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

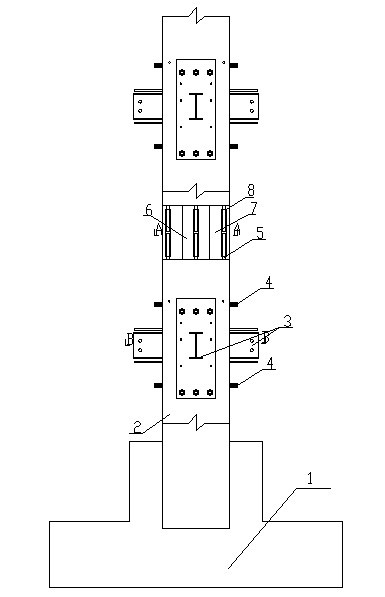

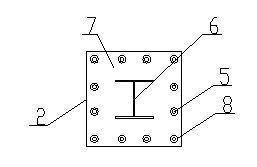

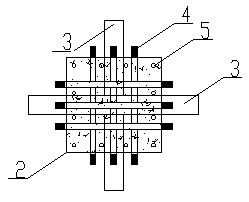

[0021] Embodiment 1: see Figure 1-4 , the prefabricated reinforced concrete structural column 2 for the prefabricated building of the present invention has a rectangular or square cross-section, and the longitudinal force in the concrete (including the connection node position with the beam) is made of the designed load-bearing steel bar 5 as the column reinforcement skeleton, and at the connection node with the beam Parts (take the cross connection beam as an example), there are joints 3 for the cross section of the column protruding from the side (internal connection with the column reinforcement), and at the position of the upper and lower structural steel bars of the connection beam, each has a column protruding from the side of the column with a diameter larger than that of the beam One level of structural steel bar, 4 connecting steel bars with external threads, the protruding thread length is 5cm, the thread reaches the side of the column, the height difference of cross...

Embodiment 2

[0024] Example 2: see Figure 5-16 , as in embodiment 1, the prefabricated reinforced concrete column 2 section shape can be L shape ( Figure 5 ), T-shaped ( Figure 6 ), cross ( Figure 7 ), a glyph ( Figure 8 ), at least one end of the longitudinal end face has protruding connecting steel joints 6 and protruding connecting column reinforcing bars 5; the connecting nodes of columns and beams have profiled steel joints 3 protruding from the side of the columns and connecting reinforcing bars 4 with threads on each side of the connection. The inner skeleton of the concrete column is still the column steel bar 5, and there is no post-cast section of concrete left. For column-to-column connections see Figure 5-8 , column to beam connection see Figure 9-16 ,in Figure 13-16 They are respectively connected cantilever structures.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com