Integrated coil assembly with diversifying three-phase coils and method for manufacturing integrated coil assembly

A technology of three-phase coils and manufacturing methods, applied in the direction of manufacturing motor generators, shape/style/structure of winding conductors, electrical components, etc., to achieve the effects of reducing wires, saving space, and improving motor efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] In order to have a further understanding and understanding of the structural features and the achieved effects of the present invention, the preferred embodiments and accompanying drawings are used for a detailed description, as follows:

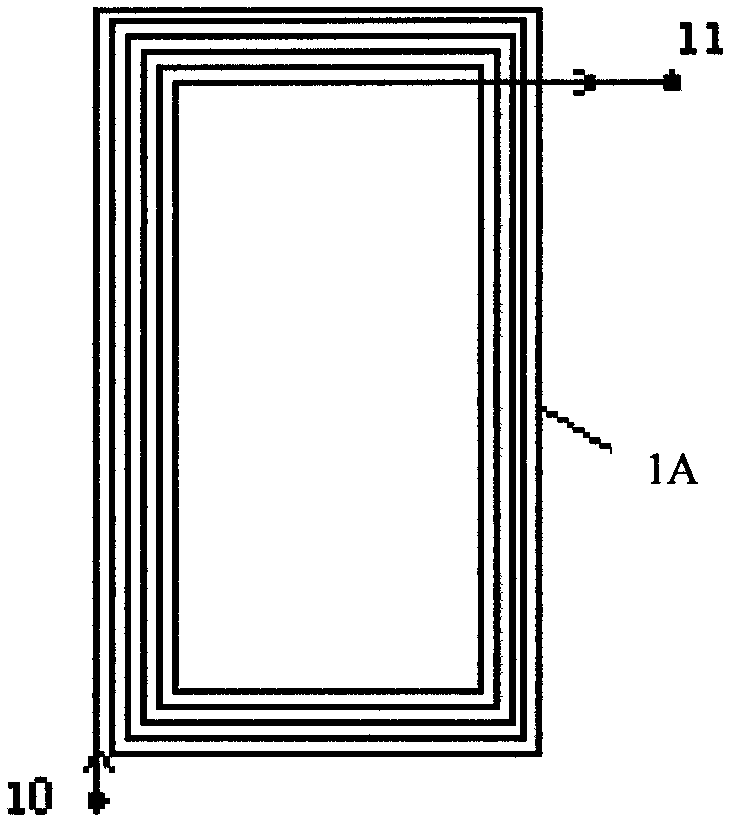

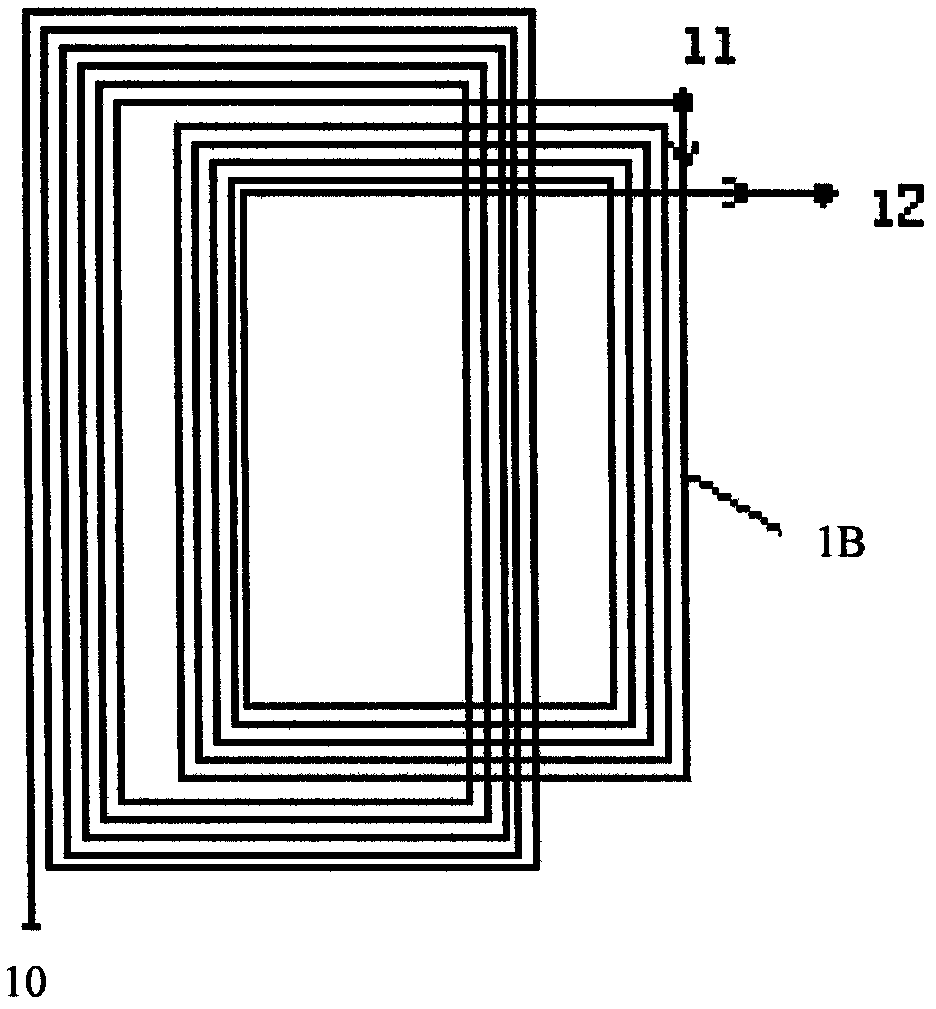

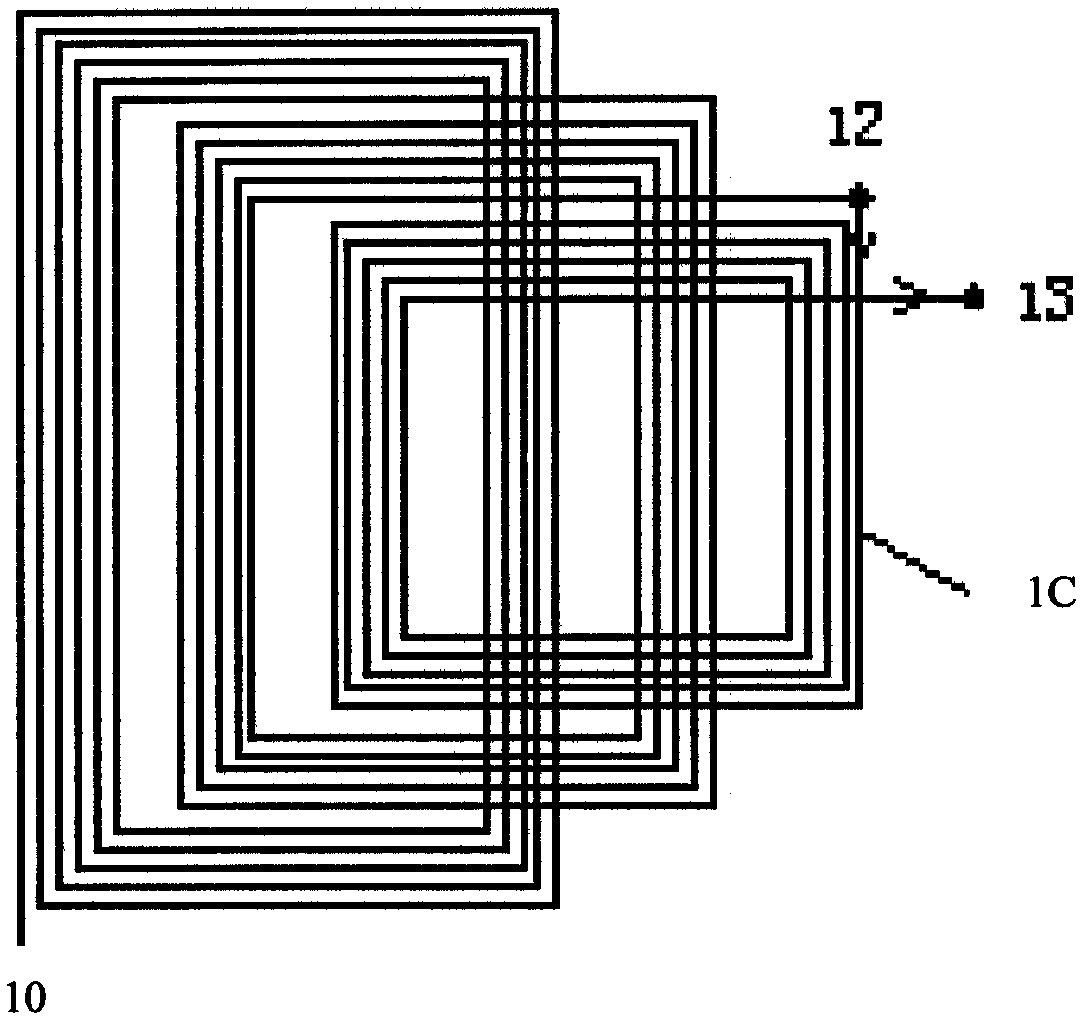

[0048] For a better description of the improved coil set, refer to Figure 1A-Figure 1C , these figures show the winding sequence of a three-phase motor coil set. For a three-phase motor, since there are three phases, the coil therefore contains a three-coil circuit. The number of coil loops per coil is equal to the number of phases. The winding of the coil loop is supported by a winding fixture and a pay-off machine ( Figure 1A-Figure 1C not yet shown). The winding jig and the wire pay-off machine are only used in conjunction with the present invention, and do not constitute any protected part of the present invention, but the winding sequence constituting the coil loop is the part claimed by the present invention.

[0049] The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com